11 overload protection – motor torque, 2 motor torque calculation parameters – R&M Materials Handling HOIST MONITORS User Manual

Page 55

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

55/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

11 Overload protection – Motor torque

11.1 Overload protection instructions

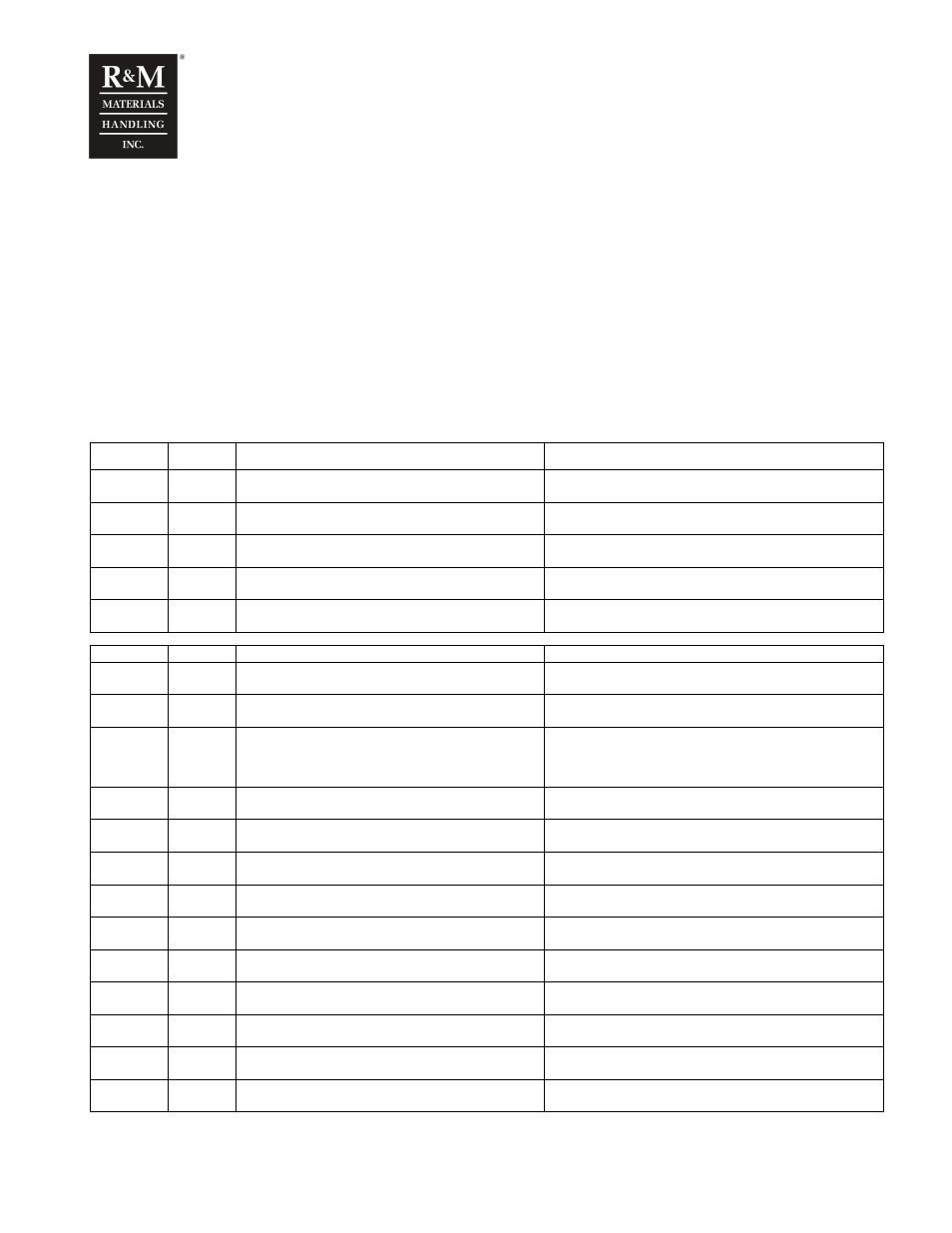

11.1.1 Motor torque calculation-system

The parameters as described in the table “Motor torque calculation parameters” must be checked and

if needed adjusted, before the calibration sequence is carried out. The unit used these values in order to

calculate the actual load. After the calibration has been done, it is recommended to write down the values

of the parameters of group “3-2 MC values” and “4-7 Load param”.

11.1.2 Motor torque calculation parameters

Parameter

Value

Description

Note

4

Start-up

Start-up menu

Accessible with password 4: 8124

4-4

T1

T1 parameters

4-4-1

T1 operat.

B NTC

Determines the type of thermistors in the low speed

windings, connected to the temperature 1 input

Type “B” is presently used as standard

4-5

T2

T2 parameters

Accessible with password 4: 8124

4-5-1

T2 operat.

B NTC

Determines the type of thermistors in the fast speed

windings, connected to the temperature 2 input

Type “B” is presently used as standard

Parameter

Value

Description

Note

4-7

Load param

Load calculation menu

Accessible with password 4: 8124

4-7-1

Load meas.

Motor

Selects the motor torque calculation method

4-7-2

Load rate%

10

Load increase rate for controlling the hoisting in two

step control, speed change to fast speed is allowed

when actual load change within 200ms < parameter 4-

7-2.

See also description in chapter “Sudden load increase

supervision” of this manual for further details

4-7-3

R0_F

0.00 –

1000

Resistance of the fast speed windings at temperature

T0

If accurate measurements can not be performed, one has to

rely on the information given in the motor data files.

4-7-4

R0_S

0.00 –

1000

Resistance of the slow speed windings at temperature

T0

If accurate measurements can not be performed, one has to

rely on the information given in the motor data files.

4-7-5

T0

“nn” C

Temperature T0 “nn” at the time when measurement is

carried out, in degrees Celsius

If accurate measurements can not be performed, one has to

rely on the information given in the motor data files.

4-7-6

Temp_slow

T1

Temperature measurement channel for the motor slow

speed windings

4-7-7

Temp fast

T2

Temperature measurement channel for the motor fast

speed windings

4-7-8

C2F

143

Coefficient 2 for fast speed

Additional motor losses in fast speed windings. Setting is

motor dependent

4-7-9

C2S

236

Coefficient 2 for slow speed

Additional motor losses in slow speed windings. Setting is

motor dependent

4-7-10

C1F

165

Coefficient 1 for fast speed

Iron losses in fast speed windings. Setting is motor

dependent

4-7-11

C1S

255

Coefficient 1 for slow speed

Iron losses in slow speed windings. Setting is motor

dependent

4-7-12

ki

0.0 - 300.0 Reduction factor for current transformer [A/V]

See appendix 3 “Current Transformer Table” of this

manual for the correct setting