R&M Materials Handling HOIST MONITORS User Manual

Page 53

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

53/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

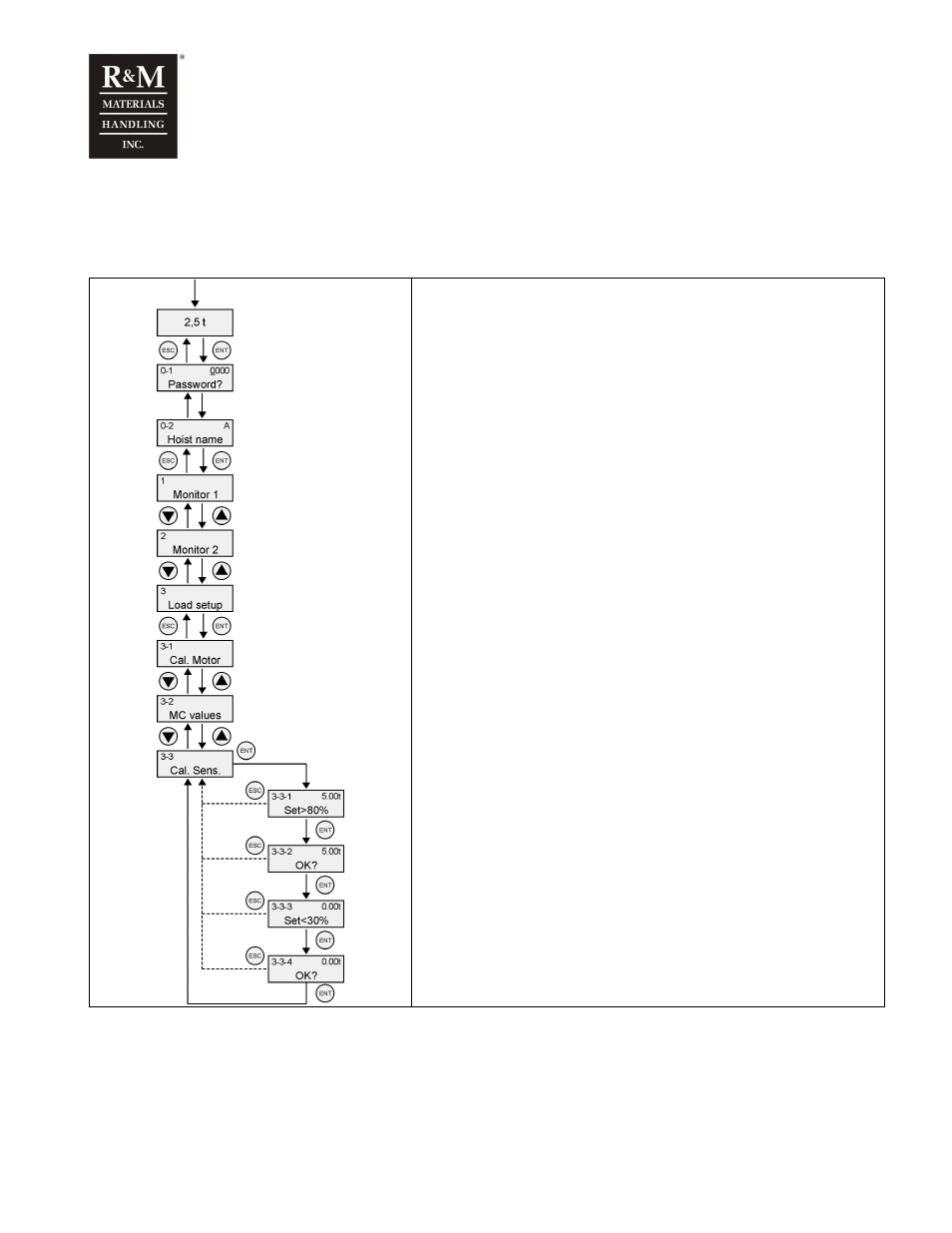

10.3 Load calibration sequence with load sensor

Before carrying out the calibration procedure, make sure that the load sensor amplifier (if

present) is correctly installed and calibrated. Refer to the chapter “Load sensor adjustment”

of this manual for instructions.

Power On

Enter password 0732. Display will jump to menu 3

parameters when one hoist is being calibrated.

If there is more than one Hoist (Multi hoisting mode) then

the hoist must be selected by a “Letter” Name. .

Go to menu 3-3-1.

Hang a higher test-load of 80…130% of the rated load of

the hoist in the hook and make sure the load hangs freely

and steady. Enter the value of the test load (in tons).

Confirm the correct value with the ENT button and wait until

the next text appears.

Hang a lower test-load of less than 30% of the rated load of

the hoist in the hook. Typically this is an empty hook. Make

sure the load hangs freely and steady. Enter the value of

the test load (in tons, empty hook = “0.00t”).

Confirm the correct value with the ENT button. The display

shifts automatically back to “Cal. Sens.” when the values

are accepted.

Run the calibration sequence according to the display instruction.

When the calibration is done, write down the load setup values of parameters 3-4-1, 3-4-2, 3-

4-3 and 3-4-4 in the commissioning table.