13 faults and warnings, 1 faults, 1 fault codes and description – R&M Materials Handling HOIST MONITORS User Manual

Page 66

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

66/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

13 Faults and warnings

13.1 Faults

Fault means that the hoist control unit has detected a situation that prevents the hoist from running. The

hoist control unit stops the motion, indicates the fault text on the display and illuminates the red LED

continuously on both the unit and display. Depending on the detected situation and parameter settings,

only hoisting or only lowering is allowed, or running the hoist is totally prevented by the hoist-monitoring

unit.

The fault messages shown on the display are given in the table below. The messages appear when the

corresponding fault is detected. The message disappears automatically when the corresponding fault

situation is cleared. Also it is possible to clear the message and return to the original display by pushing

the ENT–button. However, as long as the fault is active, the red LEDs are illuminated and the fault

message can be read from the status mode.

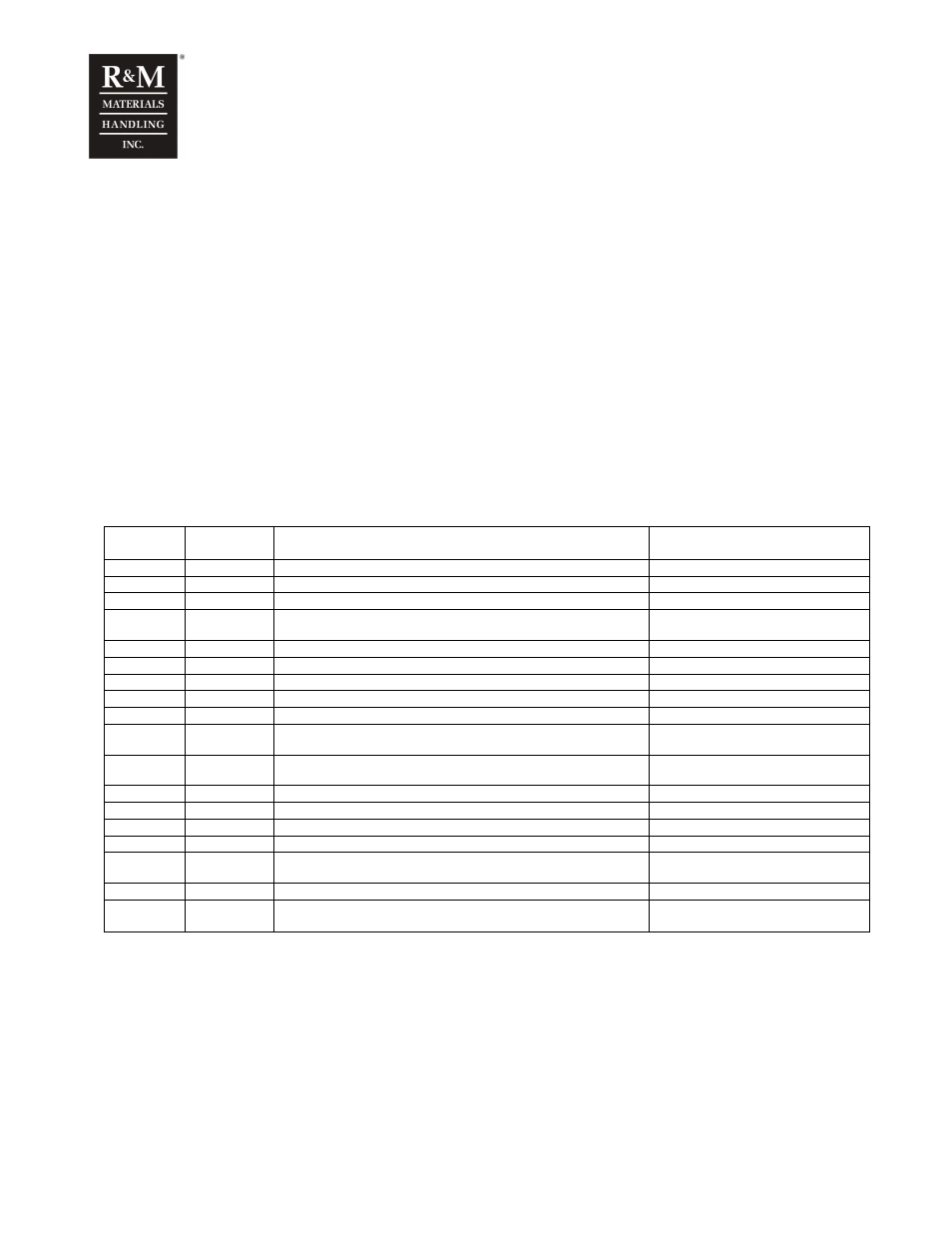

13.1.1 Fault codes and description

Fault name

Code

(Fault Logger)

Description

Running

Hoist OL

F_OL

Hoist overload

Hoisting prevented, lowering allowed

Motor OT

F_OT

Hoist motor overtemperature

Hoisting (and lowering) prevented

Int. relay

F_SR

A fault detected in the internal safety relay

Running prevented

RUN act.

F_Run

A fault detected in controlling the direction outputs, only in two-step

control

Running prevented

Run FB

– *)

The hoist stops although the unit controls it to run

Controls to stop, new start possible

Brake

F_Br

Hoist brake does not open, only in motor based load calculation

Lowering prevented

Br wear

F_Brw

Hoist brake worn-out, only when the sensor applied

Hoisting (and lowering) prevented

Sensor ch.

F_SCh

Measurement signal out of acceptable range

Hoisting prevented

Curr.meas.

F_Ain

Measurement signal out of acceptable range

Hoisting prevented

Supply vol

F_SPh

Main supply fault, one phase missing, only when main supply

measured

Running prevented

Phaseorder

F_Sor

Main supply fault, incorrect phase order, only when main supply

measured

Running prevented

Mparameter F_MP

Internal parameter reading or writing fault

Running prevented

Cparameter

F_CP

Internal parameter reading or writing fault

Running prevented

CAN bus

F_CAN

CAN bus communication fault, only in multi hoisting

Running prevented

Bridge OL

F_BOL

Overload in calculated bridge load, only in multi hoisting

Hoisting prevented, lowering allowed

Bridge RS

F_BRS

Fault in multi hoisting, requests for running or stopping not

simultaneous

Running stopped, new start possible

Slack Rope

– *)

Slack rope function is active

Lowering prevented

No Signal

– *)

Communication fault between unit and display or

Internal processor fault

Running possible

Running prevented

– *)These faults are not collected into the fault logger (parameter 5-2)