R&M Materials Handling HOIST MONITORS User Manual

Page 19

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

19/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

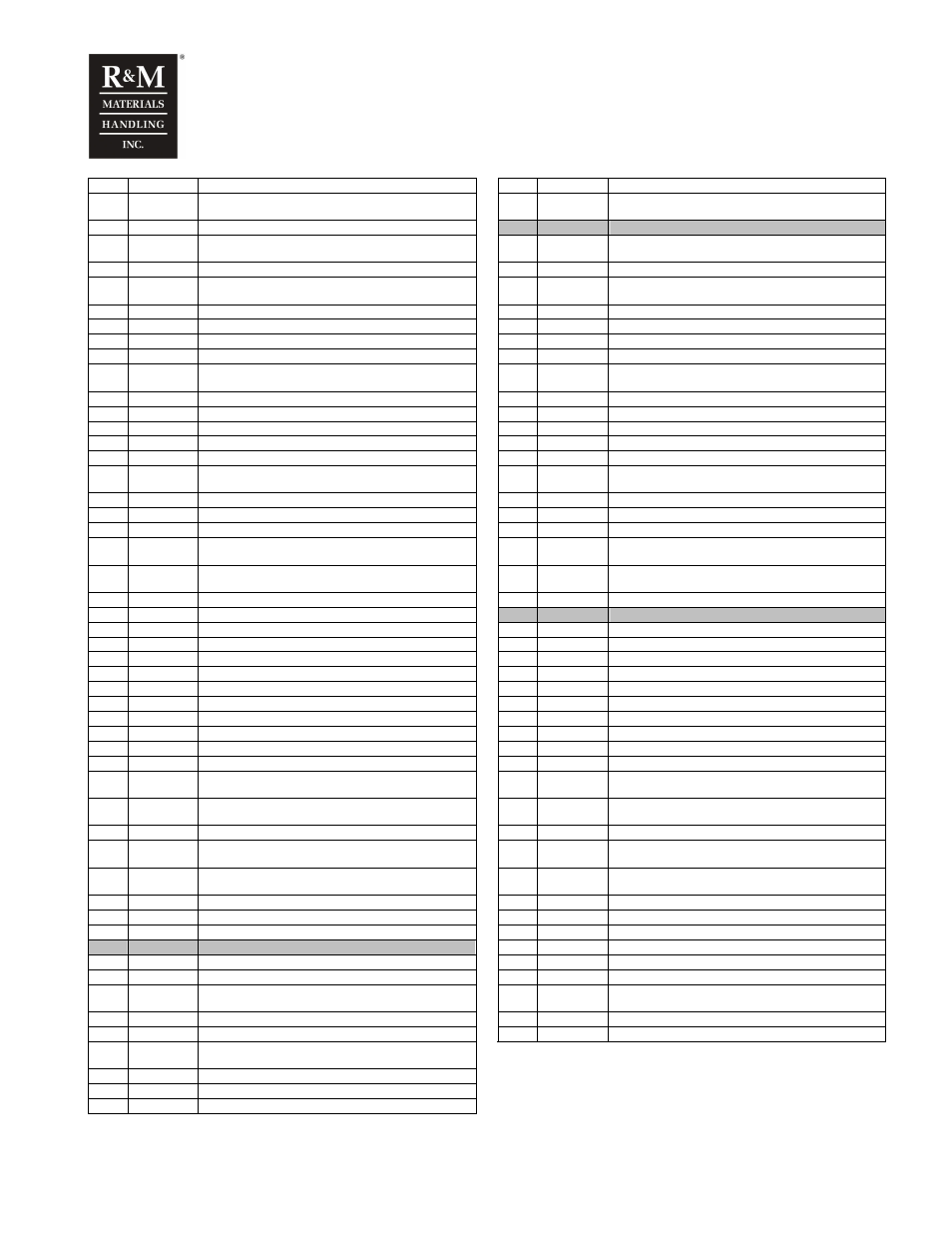

4-3

ROUT

Relay output parameters

5-3

Reset log

Resets the fault log by pushing the ENT button..

4-3-1

ROUT oper. Selects the function of the relay output

5-3

Reset log ?

The reset action must be confirmed by pushing the ENT

button once more

4-3-2

ROUT logic

The operation logic of the relay:

6

Design

Design values menu. Accessible password level 6

4-3-3

ROUT LoadX The load limit to switch the relay is entered here

6-1

Hoist name

Identifying letter of the hoist-monitoring unit, A, B, C, D

or E.

4-3-4

TempX meas The temperature measurement operation

6-2

Unit No

The serial number of the hoist.

4-3-5

TempX lim

The temperature limit

6-3

Class

Mechanical class for the hoist according to the FEM /

ISO duty classes.

4-4

T1

Temperature measurement channel 1 parameters

6-4

Nom. Load

Rated load of the single hoist connected to the unit

4-4-1

T1 operat.

Selects the function channel 1.

6-5

Nominal ED Rated ED value of the hoist

4-5

T2

Temperature measurement channel 2 parameters

6-6

Sp ratio

Speed ratio.

4-5-1

T2 operat.

Selects the function channel 1.

6-7

Max ST

Maximum allowed number of starts

4-6

AOUT

Analogue output parameters

6-8

Max E-stop

Maximum allowed number of interrupted hoists

(emergency stops)

4-6-1

AOUT oper. Selects the function of the analogue output

6-9

Max RT

Maximum allowed run-time in hours

4-6-2

Zero load

Sets the voltage level with zero-load. Range 0…10V

6-10

D SRT3

Designed running hours, power three.

4-6-3

Nom. Load

Sets the voltage level with rated load. Range 0…10V

6-11

D SRT8

Designed running hours, power eight.

4-7

Load param Load calculation parameters

6-12

D SL3

Design constraint for hoisting cycles, power three

4-7-1

Load meas.

Selects the load calculation method:

6-13

D SL8

Design constraint for hoisting cycles, power eight

4-7-2

Load rate%

Load increase rate for controlling the hoisting in two step

control.

6-14

MaxST MFI1 Max number of MFI1 starts.

4-7-3

R0_F

Resistance of fast speed windings at temperature T0

6-15

MaxRT MFI1 Max running time for MFI1.

4-7-4

R0_S

Resistance of slow speed windings at temperature T0

6-16

MaxST MFI2 Max number of MFI2 starts.

4-7-5

T0

Resistance measuring temperature T0

6-17

MaxRT MFI2 Max running time for MFI2.

4-7-6

Temp_slow

Temperature measurement channel for the motor slow

speed windings.

6-18

Max Br

Max number of braking actions.

4-7-7

Temp_fast

Temperature measurement channel for the motor fast

speed windings.

6-19

Max Control Max number of Control (starts)

4-7-8

C2F

Coefficient 2 for fast speed

6-20

Password

Set password level 1 (4digits).

4-7-9

C2S

Coefficient 2 for slow speed

7

GO-setup

GO-settings menu. Accessible password level 7

4-7-10 C1F

Coefficient 1 for fast speed

7-1

Cycles

Number of hoisting cycles

4-7-11 C1S

Coefficient 1 for slow speed

7-2

MFI1 RT

MFI1 running time

4-7-12 ki

Reduction factor for current transformer [A/V]

7-3

MFI1 ST

MFI1 starts

4-7-13 Acc-t slow

Acceleration time from stop to slow speed.

7-4

MFI2 RT

MFI2 running time

4-7-14 Acc-t fast

Acceleration time from slow speed to fast speed.

7-5

MFI2 ST

MFI2 starts

4-8

Hoist ctrl

The selection for the hoist control method

7-6

RT slow

Run-time in slow speed

4-9

Slack rope

Slack rope function parameters

7-7

RT fast

Run-time in fast speed

4-9-1

SR select

Selects the slack rope function

7-8

No. OT

Number of hoist motor overtemperature incidents.

4-9-2

Load limit

The slack rope limit

7-9

No. OL

Number of hoist overload incidents

4-10

Single sup

7-10

E-stops

Number of emergency stops

4-10-1 OT run ?

Selects the action when the motor temperature exceeds

the limit or when “Fault, Br wear” occurs

7-11

ST up

Number of starts in up direction

4-10-2 OT limit

When NTC type sensor is applied the limit value for the

hoist motor overtemperature

7-12

ST down

Number of starts in down direction

4-10-3 Supply sup

Selects the supply voltage supervision.

7-13

ST fast

Number of starts to fast speed (two step control only)

4-11

Comm hoist The settings for common hoisting (multi-hoist

applications)

7-14

Max ED

Maximum ED value

4-11-1 Hoist cnt

The number of units connected with CAN bus. Range:

1…5

7-15

Over ED

Number of cases where ED value has exceeded the

rated ED value

4-11-2 Run sup.

Common hoisting supervision

7-16

SRT3

Load sum with hoist running time, third power

4-11-3 B OL

Bridge overload protection

7-17

SRT8

Load sum with hoist running time, eight power

4-11-4 B nom load

Rated load of the bridge

7-18

SL1

Load sum with hoist cycles, the first power (mean load)

5

Service

Start- menu. Accessible password level 5

7-19

SL3

Load sum with hoist cycles, the third power

5-1

S limits

The limit values to indicate the need for service.

7-20

SL8

Load sum with hoist cycles, the eight power

5-1-1

S Run time

Run time service limit

7-21

Power on

The total power on time for hoist control unit

5-1-2

S starts

Service limit for the number of starts

7-22

Temp Index

The power on time weighted with the hoist control unit

temperature

5-1-3

S SWP%

Service limit for SWP%

7-23

Max load

The maximum value of the measured load

5-1-4

S Br SWP% Service limit for the hoist brake service life

7-24

Br Count

The brake wear counter.

5-2

Fault log

The logger for the latest fault situations, the number

“n” indicates the number of faults in the logger

5-2-1

F_”XXX”

The latest fault.

5-2-2

F_”XXX”

The second latest fault.

5-2-“n” F_”XXX”

The “n” latest fault (highest number is 30).