6 monitoring items – R&M Materials Handling HOIST MONITORS User Manual

Page 30

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

30/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

6 Monitoring Items

6.1 General

In order to read the monitoring items and to program the unit, the hoist-monitoring unit is equipped with a

display. The monitoring items of the hoist-monitoring unit consist of variable read-only values. These

monitoring items are of great advantage when efficiently planning maintenance, preventive repairs,

troubleshooting and general overhauls. In addition, the monitoring values will accurately show the usage

of the hoist.

The values are stored in the memory of the hoist-monitoring unit. The stored values remain also during

power-off situations. After power-off situation the previously stored values are taken into account when

new values are calculated.

The condition monitoring items can only be read after a correct password has been given. The

manufacturer will provide a personal password with each delivery that has been acquired with this

option.

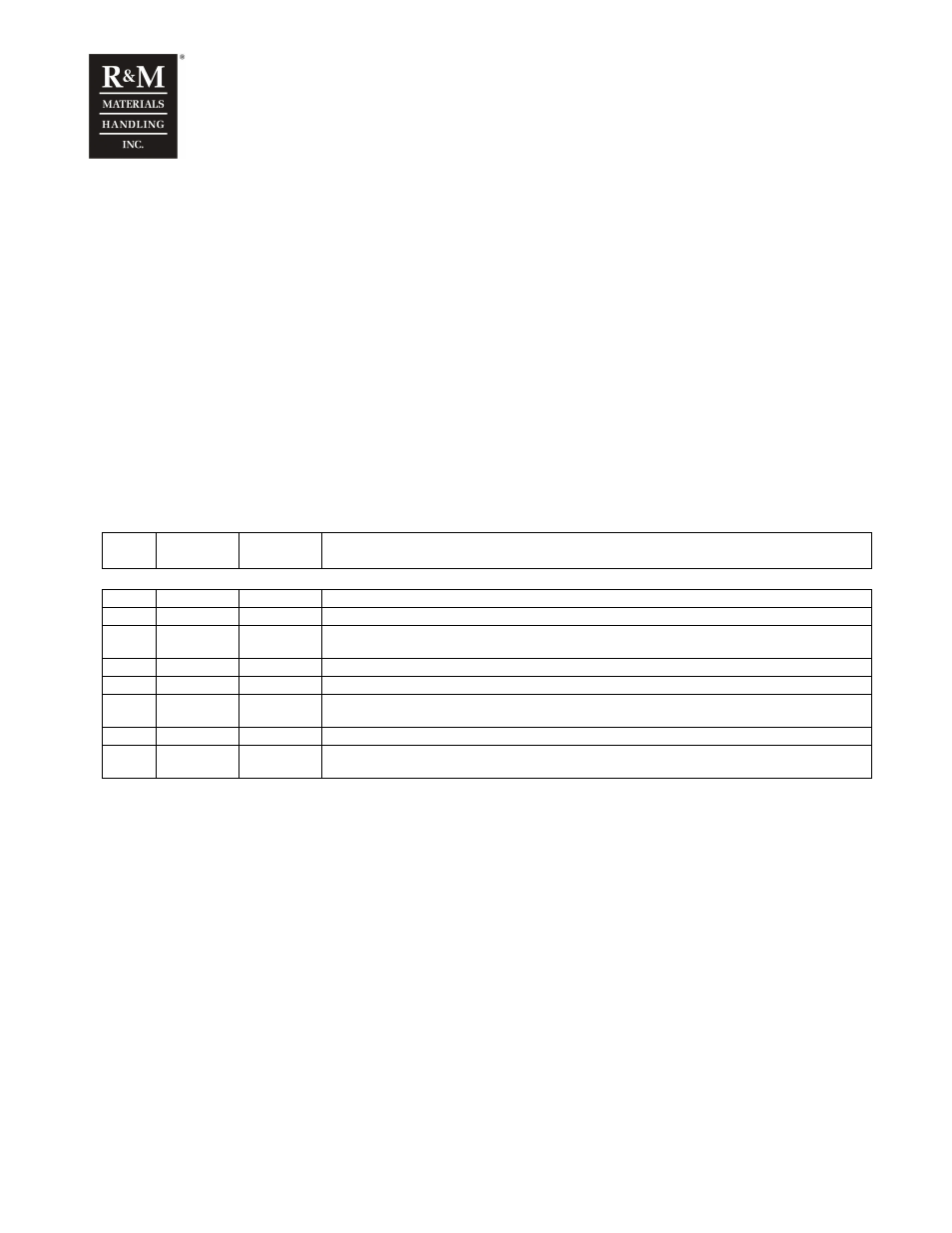

1

Monitor 1

Read only menu for condition monitoring values and measured values.

Accessible with the customer’s password.

Param. Name

Value

Description

1-1

Cond mon

Condition monitoring menu

1-1-1

SWP%

“n” %

Remaining Safe Working Period of the hoist in percentage, starting from 100%. When the SWP

counter descends to 0% (or even negative), a General Overhaul must be carried out.

1-1-2

Starts

“n”

Total number of starts of the hoist in either up or down direction. *1)

1-1-3

Run time

“n” h

Total running time of the hoist in hours. *2)

1-1-4

Cycles

“n”

Total number of hoisting cycles. *1). The number increases by one, when a load value increase

more than 20% of the rated load is lifted.

1-1-5

Mean load

“n.n” t

Average of the handled load during the recorded cycles.

1-1-6

Br SWP%

“n” %

Remaining Safe Working Period of the brake in percentage. The SWP for the brake is calculated

according to the number of Starts and E-stops (also stops at limit switch).

6.2 Primary monitoring items

The primary monitoring items are according to the ISO and FEM regulation. Depending on the hoist duty

class, the hoist is given an initial Safe Working Period (SWP). The SWP counts down according to a

calculation, which includes the running time with a certain load. Also the total run-time (independent on

the load) and the amount of starts are directly related to the hoist’s duty class and theoretical lifetime.

The primary monitoring items, related to the FEM and ISO regulations are:

-

Hoist Safe Working Period counter (SWP%)

-

Starts counter

-

Run Time counter

Monitoring items can only be read if the hoist-monitoring unit is equipped with a display, either

mounted on the unit or in the pushbutton station.