R&M Materials Handling HOIST MONITORS User Manual

Page 31

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

31/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

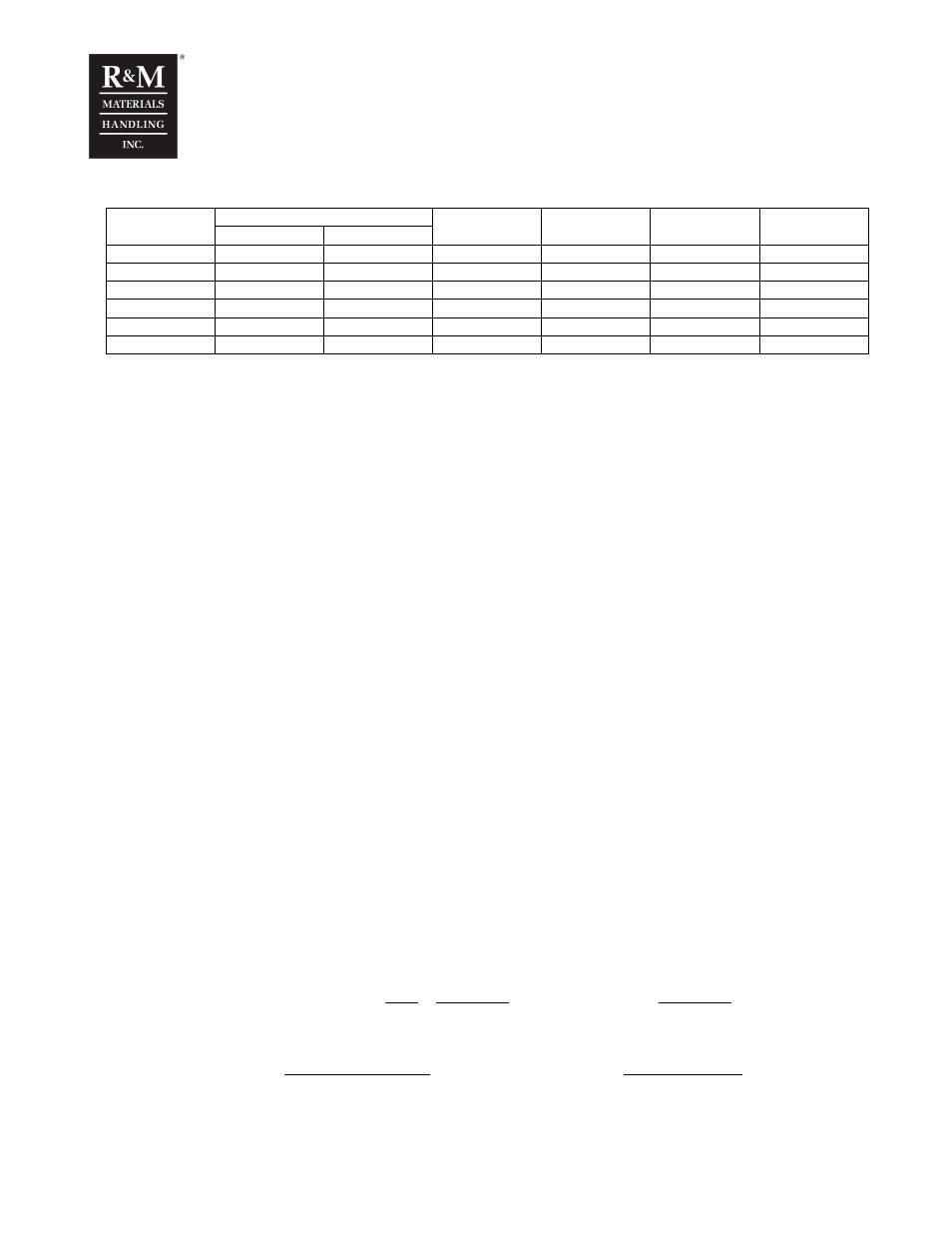

Relation between the hoist duty class and the primary monitoring items:

Hoist duty class

Class code

ISO

FEM

Starts [n]

Par. 1-1-2

Run time [hr.]

Par. 1-1-3

SWP / SRT3 [hr.]

Par. 2-13

SWP / SL3 [n]

Par. 2-17

3

M3

1Bm

480.000

3.200

400

10.000

4

M4

1Am

1.134.000

6.300

800

24.000

5

M5

2m

3.000.000

12.500

1.600

64.000

6

M6

3m

7.500.000

25.000

3.200

160.000

7

M7

4m

18.000.000

50.000

6.300

378.000

8

M8

5m

42.000.000

100.000

12.500

750.000

6.2.1 Starts counter

The Starts counter counts the number of instants the hoist is started. A start is counted when the run

command output (either hoisting or lowering) is activated, and the run feedback becomes active. If only

run command input is activated then a start is not counted.

The maximum allowed number of starts is directly related to the theoretical lifetime of the hoist. When the

Starts counter reaches the design limit value, an adequate overhaul must be performed. See the specific

actions from the hoist GO manual. The hoist-monitoring unit will not prevent running the hoist when the

Starts counter reaches the design limit value, but it will give a warning signal, indicating that safe usage

of the hoist is no longer guaranteed.

6.2.2 Run Time counter

The Run Time counter records the total amount of hours the hoist has been running, either upwards or

downwards.

The Run Time counter is not load dependent. The maximum allowed run time is directly related to the

theoretical lifetime of the hoist. When the Run Time counter reaches the design limit value, an adequate

overhaul must be performed. See the specific actions from the hoist GO manual. The hoist-monitoring

unit will not prevent operating the hoist when the Run Time counter reaches the design limit value, but it

will give a warning signal, indicating that safe usage of the hoist is no longer guaranteed.

6.2.3 Safe Working Period counter (SWP%)h

The theoretical lifetime of the hoist is presented as Safe Working Period (SWP). The SWP is based on a

calculation, including the running hours and the load in the equation. The hoist-monitoring unit displays

the SWP in percentage of the initial value. A new hoist is given a SWP value of 100%, which is in respect

to the initial SWP-hours value according to the hoist duty class. When the SWP counter reaches zero, a

general overhaul must be performed, after which the hoist shall be given a new SWP. See the specific

actions from the hoist GO manual. The hoist-monitoring unit will not prevent running the hoist when the

SWP reaches zero, but it will give a warning signal, indicating that safe usage of the hoist is no longer

guaranteed.

∑

+

=

+

∆

+

∆

=

1

1

3

1

.

3

n

i

i

i

i

n

load

nom

load

SR

ts

tf

SRT

∑

+

=

+

=

1

1

3

1

.

3

l

k

k

l

load

nom

load

SL

(

)

%

100

3

_

3

3

_

%

⋅

−

=

SRT

D

SRT

SRT

D

SWPRT

(

)

%

100

3

_

3

3

_

%

⋅

−

=

SL

D

SL

SL

D

SWPHC

SWP% = min {SWPRT%, SWPHC%}