5 basic functions – R&M Materials Handling HOIST MONITORS User Manual

Page 21

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

P.: (937) 328-5100

FAX: (937) 325-5319

21/105

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

5 Basic Functions

5.1 General

The basic functions assure the safe functioning of the hoist. The hoist-monitoring unit constantly performs

a number of checks to determine if all conditions are safe in order to proceed the motion. In case the

hoist-monitoring unit detects a potentially unsafe situation, the motion will be stopped. Depending on the

kind of fault, both hoisting and lowering is prevented or in other cases driving in the opposite direction is

allowed.

In addition to the basic functions, a wide scale of optional functions can be installed. Refer to the section

“Optional functions” or contact a manufacturer’s representative for further details.

The basic functions of the hoist-monitoring unit are:

•

Overload protection

•

Hoist motor overtemperature supervision

•

Supply phase supervision

•

Run and fault supervision

•

Starting and stopping through slow speed

•

Sudden load increase supervision

The basic functions are factory set according to specific hoist and customer’s demand.

It is possible that few basic functions can’t be used in every hoist. (e.g. Insulated network, inverter

drive)

The additional optional functions of the hoist-monitoring unit are:

•

Lifetime counters

•

Remote display

•

Multicare

•

Multi function input Options

•

Potentional Free Relay Options

•

Analog Output

When during run one of the supervised safety features value exceeds the limit, the unit will stop the

motion. Re-starting is only possible after the reason for the fault is terminated. Note that some faults are

direction dependent and running in the opposite direction will terminate the fault. Refer to the sections

that describe the supervisions for details.

The hoist-monitoring unit is equipped with two LEDs that provide operational information as follows:

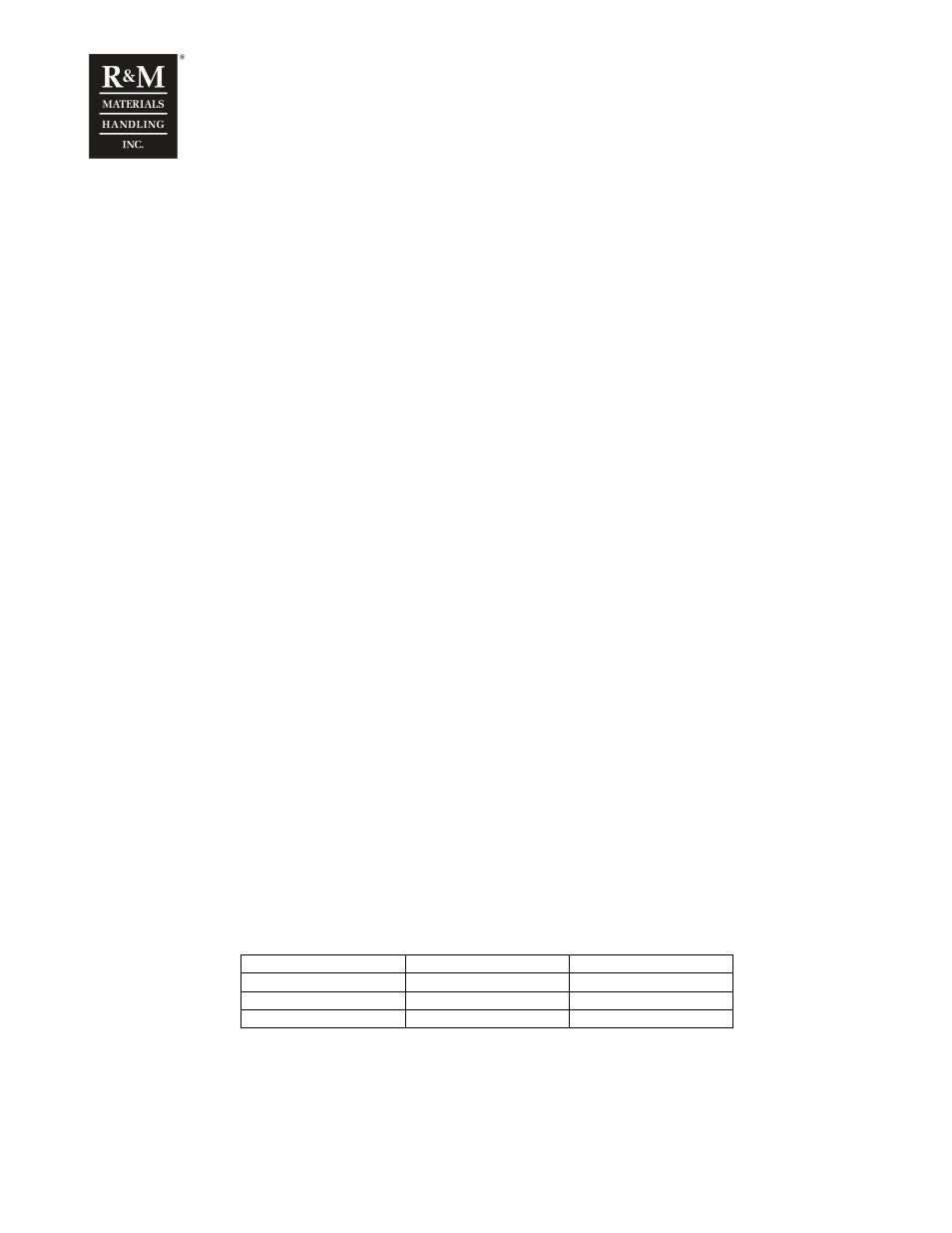

Action / LED

Green LED

Red LED

Illuminated continuously

OK, not running

Fault

Blinking

OK, running

Warning

Not illuminated

Fault

OK

OK state means that the hoist control unit is working normally and no fault or error has been detected.

Running the hoist is possible.

Warning means that a condition-monitoring value has exceeded the design value. Running the hoist is

possible, but safe operation can not be guaranteed.