Positioning the media sensors – Printronix SL4M User Manual

Page 44

44

Chapter

2

Positioning the Media Sensors

3.

Remove the printhead alignment tool (yellow screwdriver) from the tool

clip.

4.

Use the printhead alignment tool to turn the printhead alignment dial.

Turn the printhead alignment dial UP for THICKER stocks and DOWN for

THINNER stocks.

5.

Close the pivoting deck by rotating the deck lock lever fully clockwise.

6.

Run a print test, such as the checkerboard or gray scale.

See “Printer Tests” on page 145.

7.

If necessary repeat steps 4 to 6 until the desired alignment is achieved.

8.

Lower the media cover.

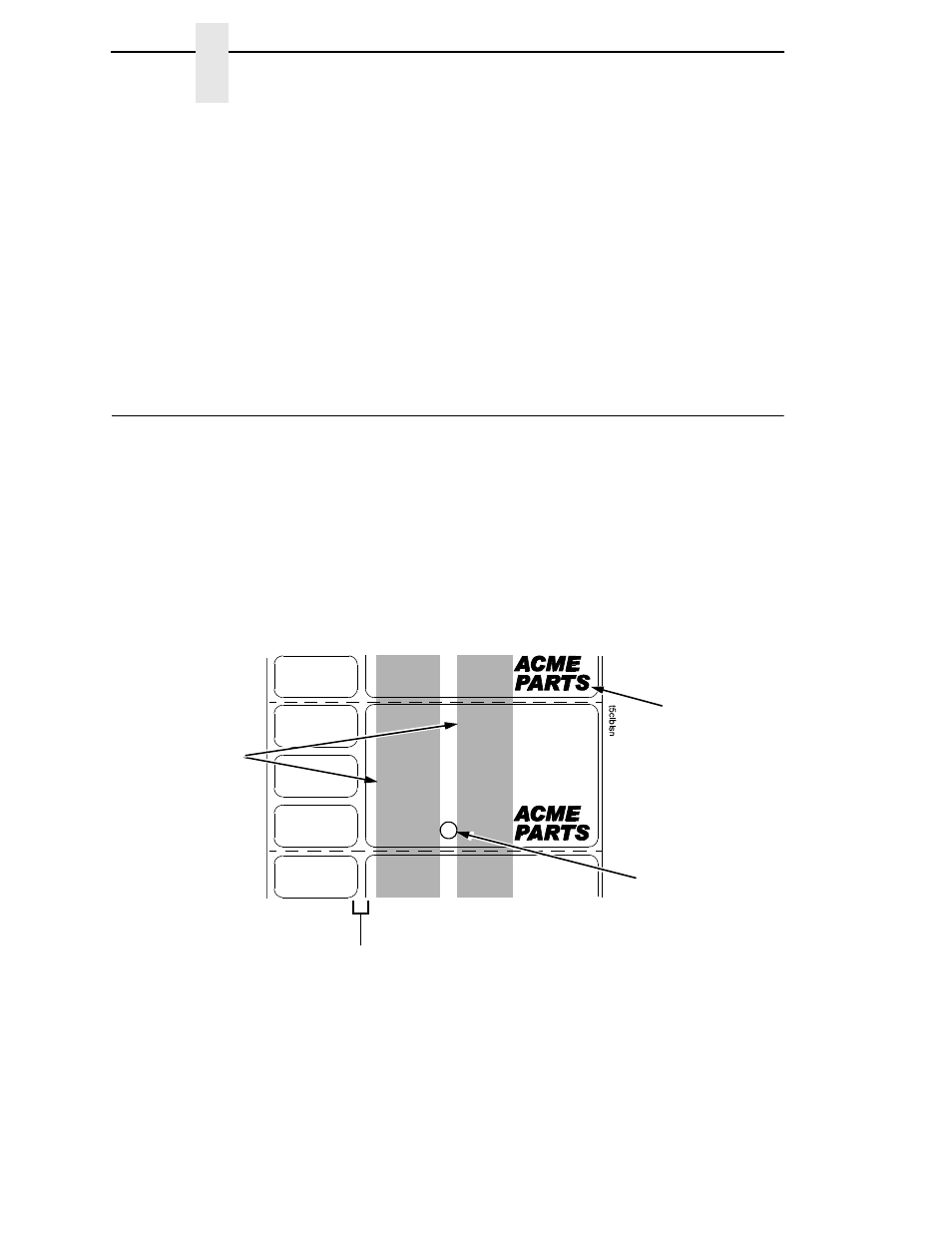

Positioning the Media Sensors

Your printer is equipped with a media sensor assembly that detects the

top-of-form position on media with label length indicators (gaps, notches,

holes, or black marks). These sensors also detect when a Paper Out

condition exists.

See page 221 for media and label length indicators.

The media sensors should not be placed in the path of media features that

could cause false gap detection or paper out faults. Such features are dark

pre-printing, rounded die-cut label corners, vertical gaps associated with

side-by-side labels, and extraneous cut-outs, as shown below.

Vertical Gap and

Rounded Die-cut

Label Corners

Extraneous Cut-out

Dark Pre-printing

Position the media

sensors in either of

the grey shaded

areas.