Most frequent problems and solutions – Printronix P8000 Series Cartridge Ribbon Printer User Manual

Page 289

Printing a Hex Dump

289

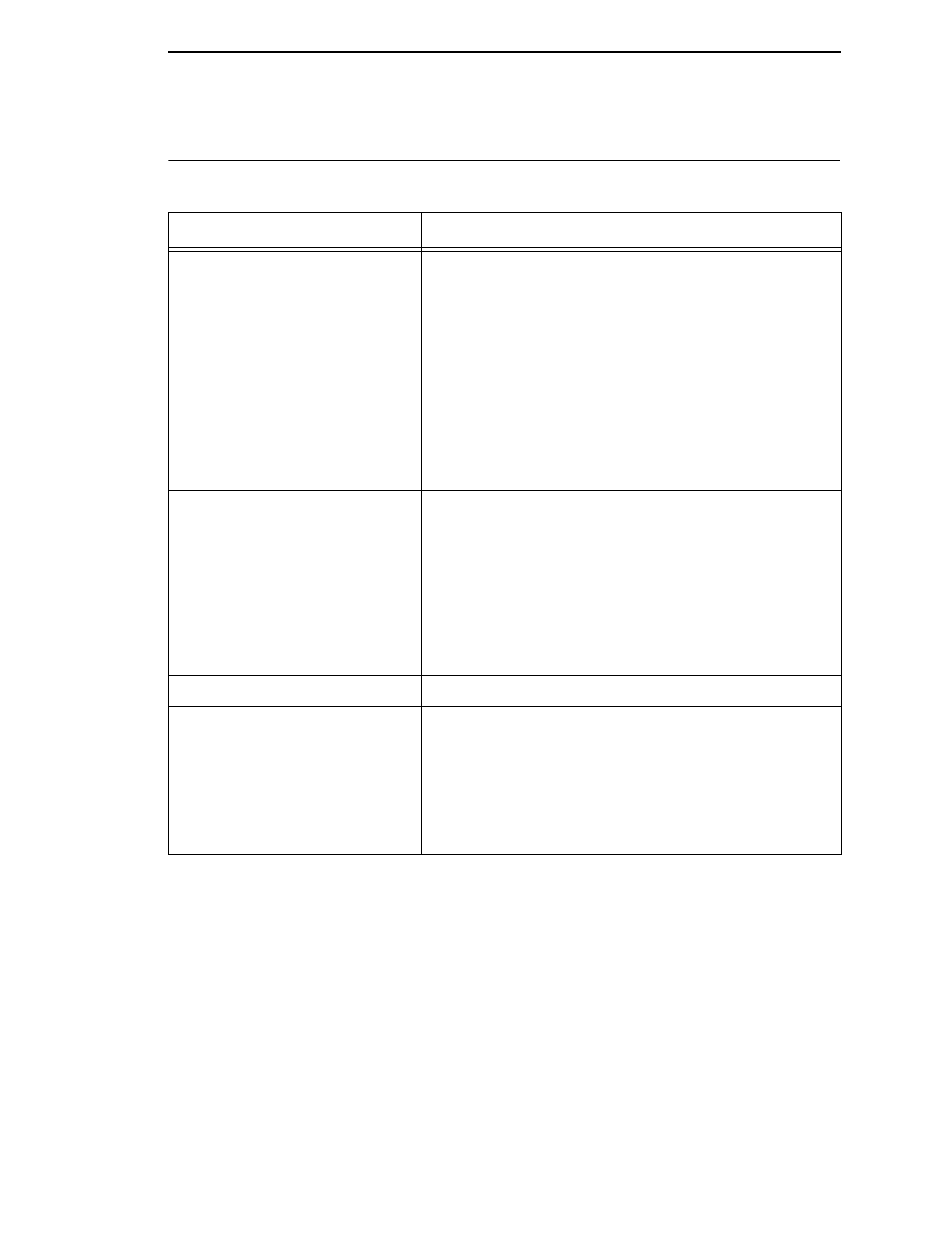

Most Frequent Problems and Solutions

Problem

Corrective Action

Poor print quality

•

dark print

•

light print

•

light print on half of the page

•

missing dots or characters

•

smeared print

•

wavy vertical lines

•

Adjust the forms thickness lever setting. Print quality

can be affected if it is too loose or too tight.

•

Adjust the paper tension horizontally by moving the

right tractor. Print quality can be affected if it is too

loose or too tight.

•

Make sure the ribbon threads between the

hammerbank cover and ribbon mask, as shown on the

ribbon path diagram on the pedestal models. Turn the

ribbon cartridge knob clockwise to ensure that the

ribbon tracks correctly in the ribbon path.

•

Be sure to use an approved ribbon.

Torn or damaged forms

•

Reset the forms thickness lever for thicker paper.

•

Adjust the paper tension horizontally by moving the

right tractor. Too high a paper tension can cause

tearing of the tractor feed holes.

•

Check the paper slot for foreign material.

•

For thick, multipart forms, set the OPEN PLATEN @

BOF to enable. Refer to the Printer Control Menu in

the User’s Manual.

Loss of forms position

•

Set the forms thickness lever for thicker paper.

Lost dots (incompletely formed

characters)

Horizontally or vertically

misaligned character positions

Erratic character height

Vertically misaligned print

•

Lower the forms thickness lever.

•

Adjust the paper tension horizontally by moving the

right tractor. Print quality can be affected if it is too

loose or too tight.

•

Clear the paper path of any obstructions.

•

If problems persists, contact a service representative.

Most Frequent Problems and Solutions