Ohaus I150-S Indicator User Manual

Page 63

63

Using Stored Average Piece Weights:

Using Stored Average Piece Weights:

Using Stored Average Piece Weights:

Using Stored Average Piece Weights:

Using Stored Average Piece Weights:

1.

Place parts on the load receiver.

2.

To recall a stored ID code and aver-

age piece weight:

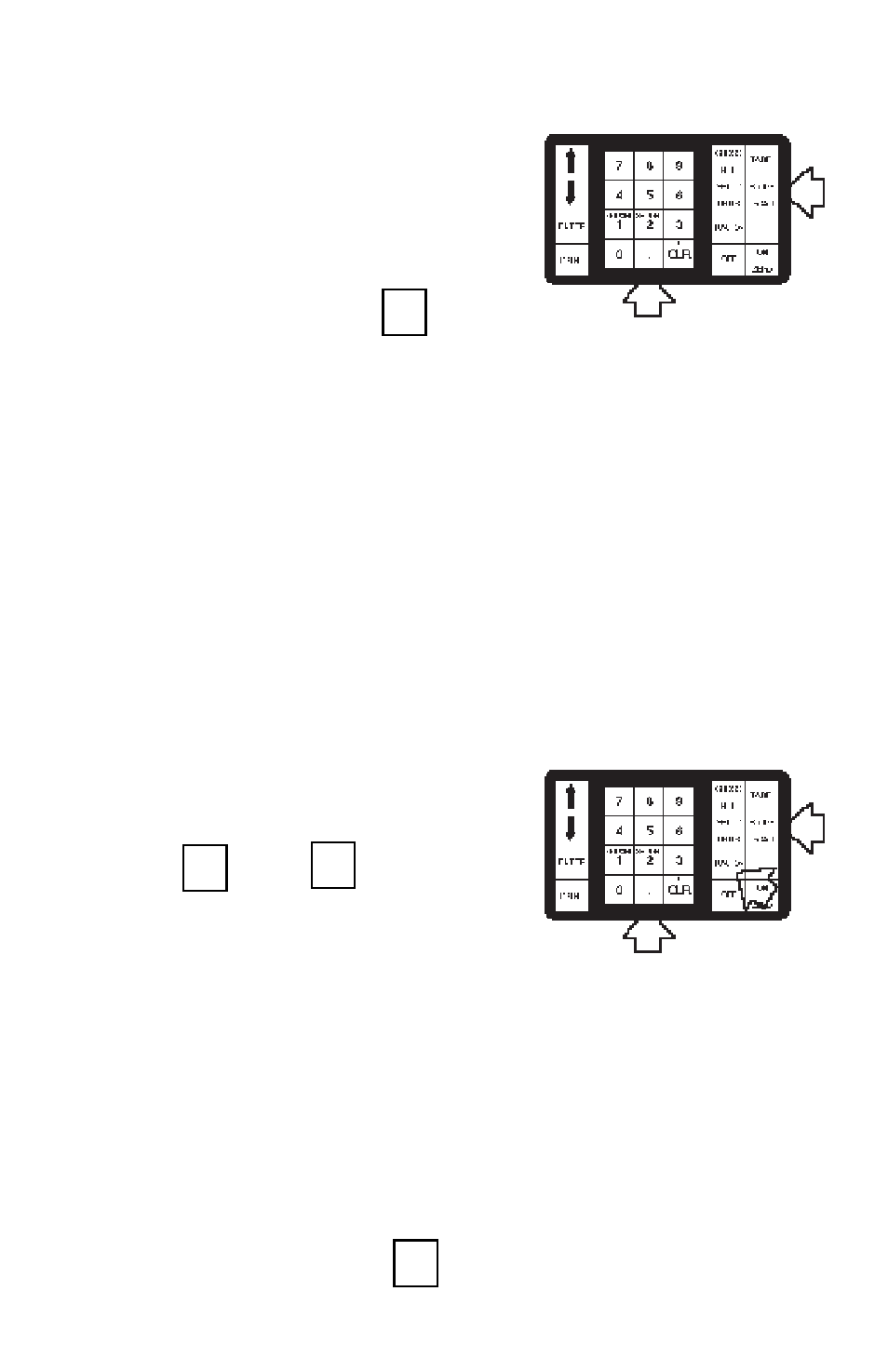

Enter the desired ID code using the

numeric keypad, then press

RECL

.

The display will show the current number

of parts on the load receiver. To change to

a different ID and average piece weight,

repeat the procedure with a new ID code.

In-Out Operation:

In-Out Operation:

In-Out Operation:

In-Out Operation:

In-Out Operation:

The I150 must be connected to a printer,

computer or terminal (using the RS-232

interface) in order to use this feature.

NOTE: IN-OUT must be selected in the

STORE parameter of the scale submenu.

1.

Place a container on the load re-

ceiver. The container may be full or

empty.

2.

Enter an ID code (up to six digits)

using the numeric keypad.

3.

Press

FUNC

, then

STORE

.

The ID code and container weight will

be stored together. The following will

be output via the RS-232 interface:

XX:XX:XX

(time) *

XX/XX/XX

(date) *

ID:

XXXXXX

(ID code)

IN:

X.XXXX lb

(current load)

* Only if time and date are enabled.

4.

Fill or empty the container as needed.

5

Enter the ID code that was stored with

the desired weight, then press

RECC

.

Enter stored ID Code,

Press RECALL.

Enter ID Code up to 6 digits,

Press FUNCTION then STORE.

STORE

STORE

STORE

STORE

STORE

RECALL

RECALL

RECALL

RECALL

RECALL

STORE

STORE

STORE

STORE

STORE

RECALL

RECALL

RECALL

RECALL

RECALL

STORE

STORE

STORE

STORE

STORE

RECALL

RECALL

RECALL

RECALL

RECALL

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION