Manual starting and stopping, How to optimize dribble and preact – Ohaus I150-S Indicator User Manual

Page 59

59

TOLERANCE - set point 2

TOLERANCE - set point 2

TOLERANCE - set point 2

TOLERANCE - set point 2

TOLERANCE - set point 2

1.

Enter the value using the numeric

keypad.

2.

Press

FNCT

, then press

SET2

.

Once entered, the current set points can

be viewed at any time by pressing FUNC-

TION followed by the set point key (1 or

2).

Manual Starting and Stopping

Manual Starting and Stopping

Manual Starting and Stopping

Manual Starting and Stopping

Manual Starting and Stopping

The process will automatically stop when

dribble and preact LEDs turn off. To stop

and restart during a process, or to simply

start:

press

FUNC

then

BTN4

.

How To Optimize Dribble and Preact

How To Optimize Dribble and Preact

How To Optimize Dribble and Preact

How To Optimize Dribble and Preact

How To Optimize Dribble and Preact

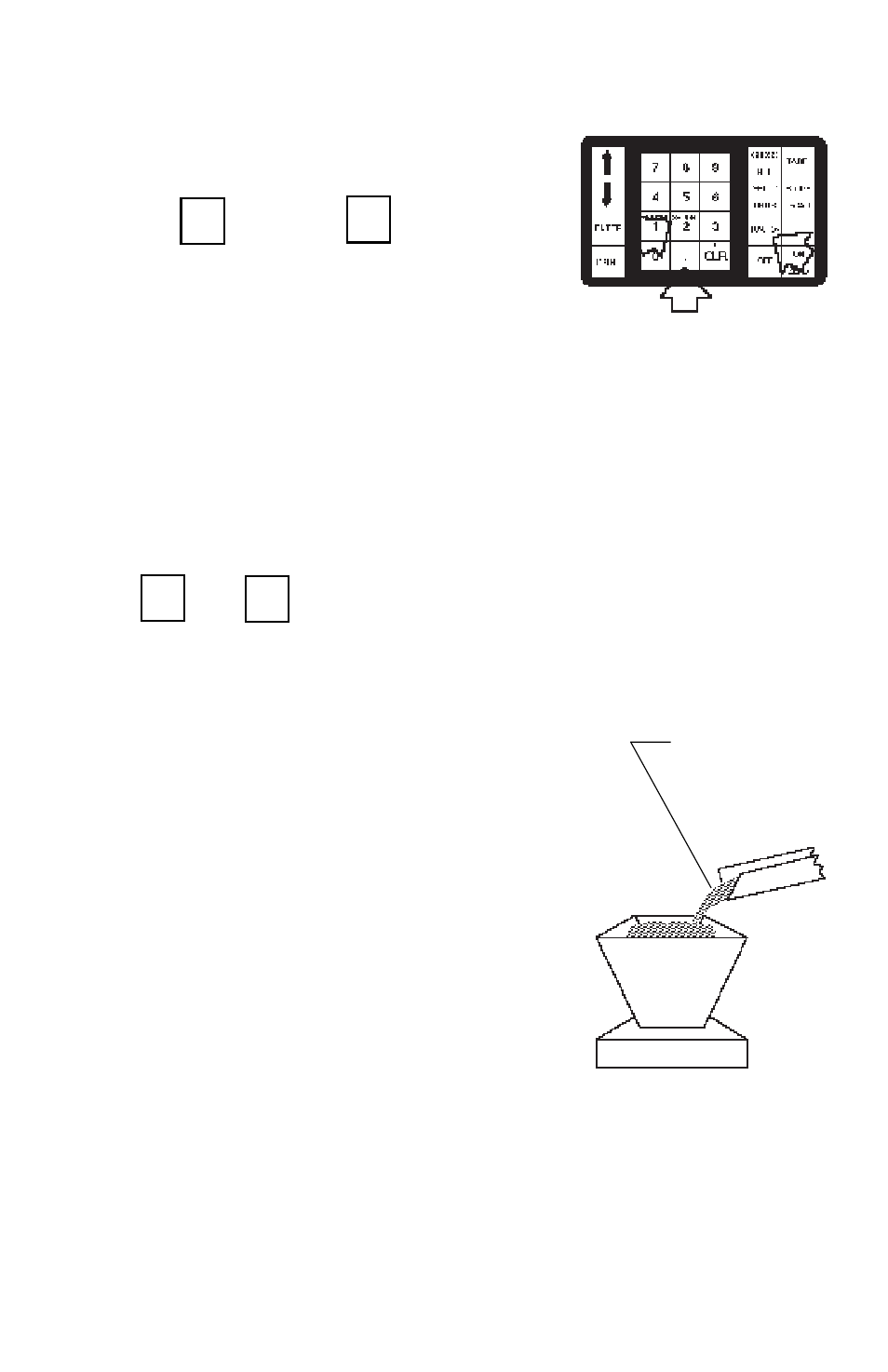

Filling Processes:

Filling Processes:

Filling Processes:

Filling Processes:

Filling Processes:

1.

Enter a value equal to 10% of the

target weight for DRIBBLE, and 0

(zero) for PREACT in the SET pa-

rameter. This will cause the feeder to

change to slow feed when the load

reaches 90% of the target weight,

and stop the feeder when the target

weight is reached.

2.

When the feeder is stopped, material

suspended in air (or the pipeline) will

fall freely into the hopper and cause

an over-fill. The weight of over-shoot

should then be entered for the

PREACT value.

3.

Access the SET parameter in the

scale submenu and change the

PREACT value.

Repeat the procedure as needed to ad-

just DRIBBLE for optimum fill time, and

PREACT for optimum accuracy.

Suspended

material empties

into hopper after

feeder stops.

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION

FUNCTION

SETPOINT

SETPOINT

SETPOINT

SETPOINT

SETPOINT

2

2

2

2

2

4

4

4

4

4