Starter motor reassembly – Generac Power Systems TXP User Manual

Page 84

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

At

CAUTION

Never clamp starter motor in a vise or strike motor with a

hammer. Motors contain two ceramic magnets. These magnets

can be broken or cracked if housing is deformed or dented.

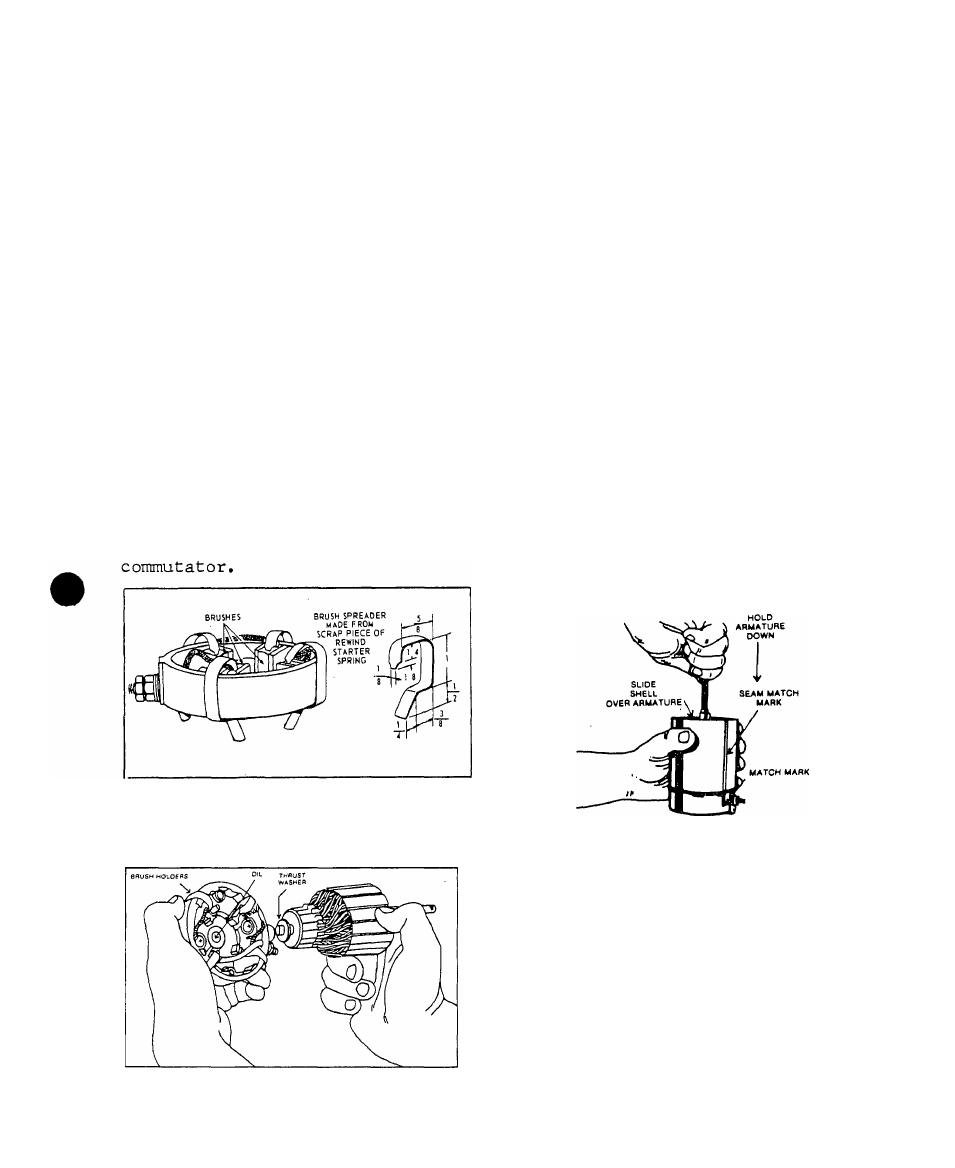

Inspect starter motor parts. Clean all dirt from armature, end cap,

motor support, etc. DO NOT SOAK BEARINGS, HOUSING OR ARMATURE IN A

CLEANING SOLUTION. Clean commutator with fine sandpaper - NOT WITH

EMERY CLOTH. Check brushes for poor seating, weak springs, dirt,

oil or corrossion. Brush spring tension should measure 17 - 25 oun

ces. When worn to 1/8 inch or less, replace brushes. See illustrat

ions below.

S T A R T E R M O T O R R E A S S E M B L Y

Make sure all. parts have been thoroughly inspected. Lightly lubri

cate end cap bearing with No. 20 oil, then reassemble as follows:

1. Insert brushes into their resp

ective holders. A locally fabrica

ted tool, as shown at right, should

be used to hold brushes clear of

2. Install armature into end cap.

Issued 5-78

3. Slide motor shell over armat

ure with notch toward end cap. Line

up marks on end cap and shell. Slide

drive cap oyer end of armature and

install through-bolts and lock wash

ers, Tighten through-bolts to 45-55

inch-pounds. Make sure armature

turns freely, then install starter

drive components as outlined previ

ously.

14.3