Issued 3-78 – Generac Power Systems TXP User Manual

Page 72

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

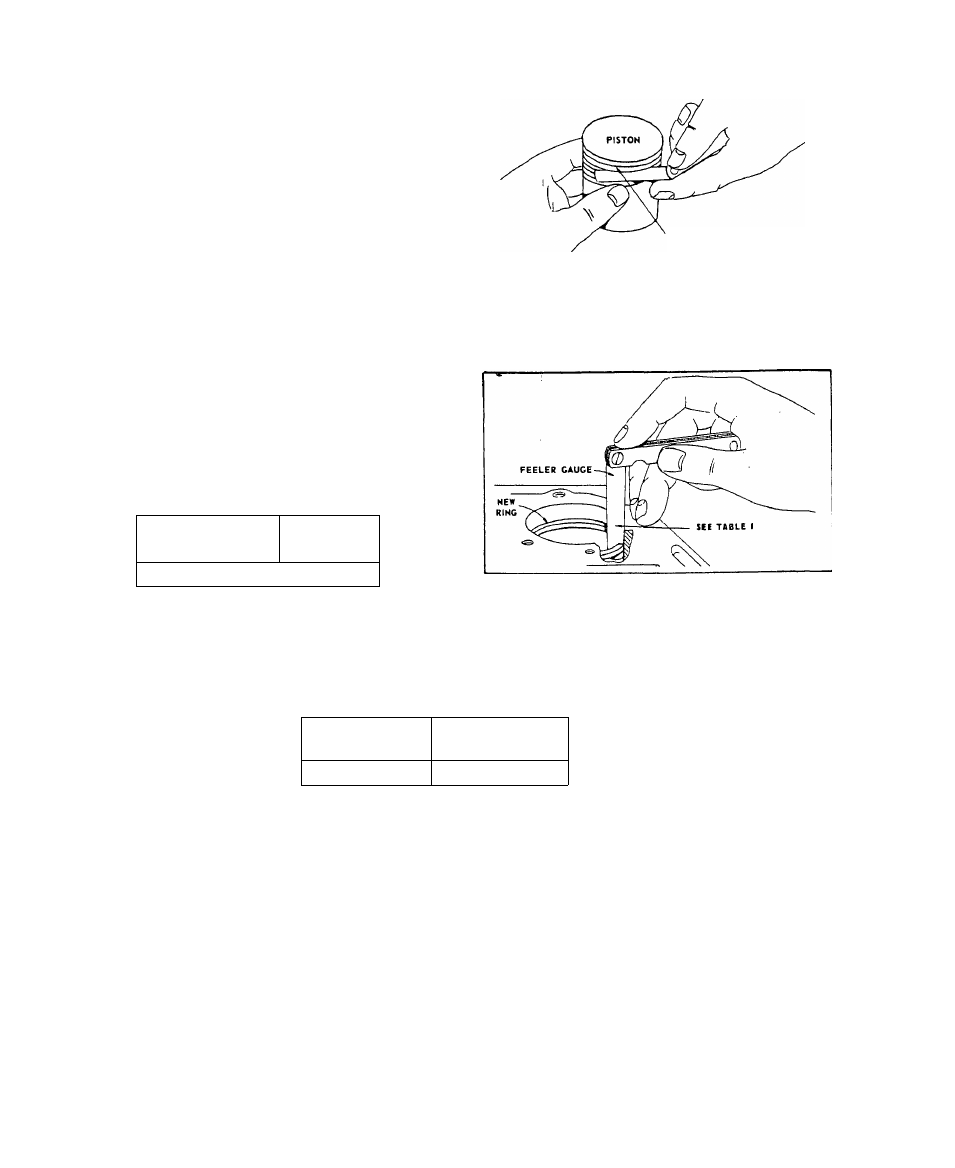

CHECK PISTON

If the piston is not to be replaced

or cylinder is not to be re-sized,

piston should be checked. Clean car

bon from top ring groove. Install a

NEW ring in the groove. If a 0.007

inch (or larger) feeler gauge can

be inserted in the space above the

ring, piston is worn and should be

replaced.

CHECK RINGS

Clean all carbon from rings and from

cylinder bore. Install old rings down

into the cylinder bore, one at a time,

one inch into the bore. Check ring gap

with feeler gauge. If gap’is greater

than shown in CHART below, replace the

ring.

COMPRESSION

RING

OIL RING,

6.035 . 1 0.045

NEW PISTON RING

CHECK CONNECTING ROD

Replace rod if crankpin bearing is scored or worn. DO NOT ATTEMPT TO

FILE OR FIT THE ROD. The following CHART shows rejection sizes of crank-

pin bearing and piston bearing holes.

CRANKPIN

BEARING

PISTON PIN

BEARING

1.252.

0.802

CHECK PISTON PIN

Replace the piston pin if it is more than 0,0005 inch out-of-round.

1 0 . 2

Issued 3-78