Cylinders – Generac Power Systems TXP User Manual

Page 75

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

CYLINDERS

11

INSPECTION

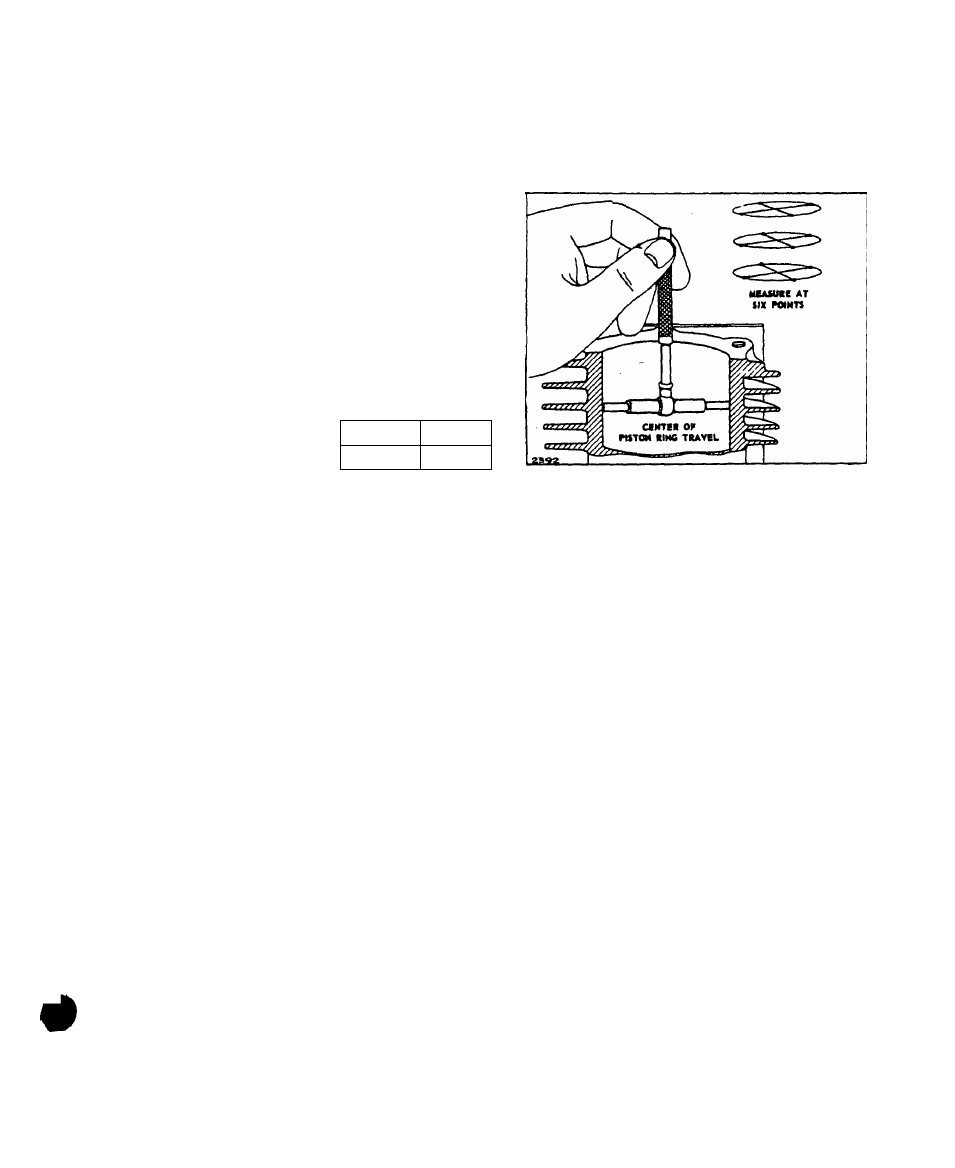

Inspect cylinders for cracks, bro

ken fins, stripped bolt holes, and

scoring of cylinder walls. Use an

inside micrometer or telescoping

gauge to determine size of cylind

er bore. Measure at-right angles

as shown at right. If bore is more

than 0,003" oversize, or more than

0.0025" out-of-round, it must be

resized. The following CHART lists

STANDARD cylinder bore diameters.

STANDARD CYLINDER

BORE DIAMETERS

MAX,

MIN.

3.4375

3.4365

RESIZING

ALWAYS RESIZE TO EXACTLY O.OlO", 0.020", or 0.030" OVER STANDARD SIZE,

AS SHOWN IN THE PRECEDING CHART, If resizing is done accurately, stan

dard oversize pistons and rings will fit perfectly and proper clearan

ces will be maintained. Cylinders can be resized with a hone. Use the

stones and lubricants recommended by the hone manufacturer to produce

the correct cylinder wall finish, (NOTE;- An acceptable honing oil can

be made by mixing 4 parts SAE 30 oil with 1 part kerosene.) If a bor

ing bar is used, a hone must be used after the boring operation to pro

duce the proper cylinder wall finish.

A

CAUTION

If cylinders are to be resized at a "Job Shop", do not take pistons

with the cylinders. If pistons and cylinders are sized to match,

seizure will occur. Oversizing must be doné to exact oversizes spec

ified in CHART.

HONING

Honing can be done with a portable electric drill. However, it is easier

to hone with a drill press. Before starting the honing operation, clean

cylinder walls thoroughly.

Issued 4-78

11.1