Assemble starter motor drive, Testing the starter motor, Starter motor disassembly – Generac Power Systems TXP User Manual

Page 83

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

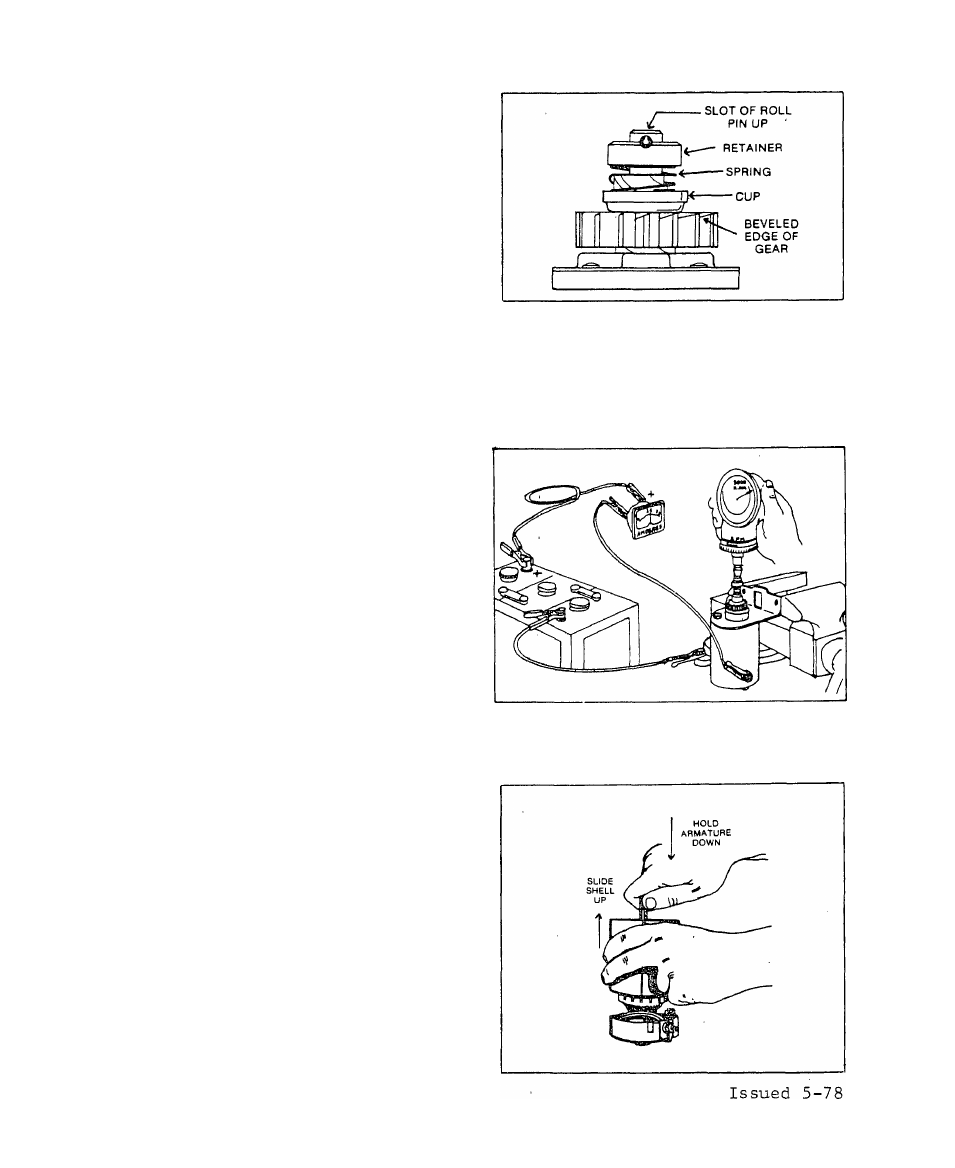

A S S E M B L E S T A R T E R M O T O R D R I V E

Install pinion gear with beveled

edge away froin starter. Install

clutch and gear onto shaft, follow

ed by cup, spring and retainer.

Press or drive roll pin through the

slot on retainer and through hole

in

armature

shaft.

Position

slot

of

roll pin up as shown. Roll pin must

be centered within 1/32 inch. Press

plastic

cap

into

position

until

it

locks into place,

T E S T I N G T H E S T A R T E R M O T O R

To check the starter motor, the following equipment is needed:

1. Tachometer capable of reading 10,000 rpm

2, A 12 volt battery

3* Ammeter capable of reading 50 Amperes

Connect

starter

motor,

battery

and

ammeter as shown at right. Insert

tachometer

into

starter

motor

and

energize motor. Motor should run

at 6200.rpm (minimum) and current

draw should not exceed 16 amperes

(maximum), DISREGARD SURGE CURRENT,

S T A R T E R M O T O R D I S A S S E M B L Y

To disa-ssemble the starter motor, first remove the starter drive as

outlined previously. Then remove the mounting bracket from the

starter motor shell by removing the two through bolts.

Push down on armature shaft and

slide the shell up and off. Remove

armature from end cap.

14.2