Generac Power Systems TXP User Manual

Page 76

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

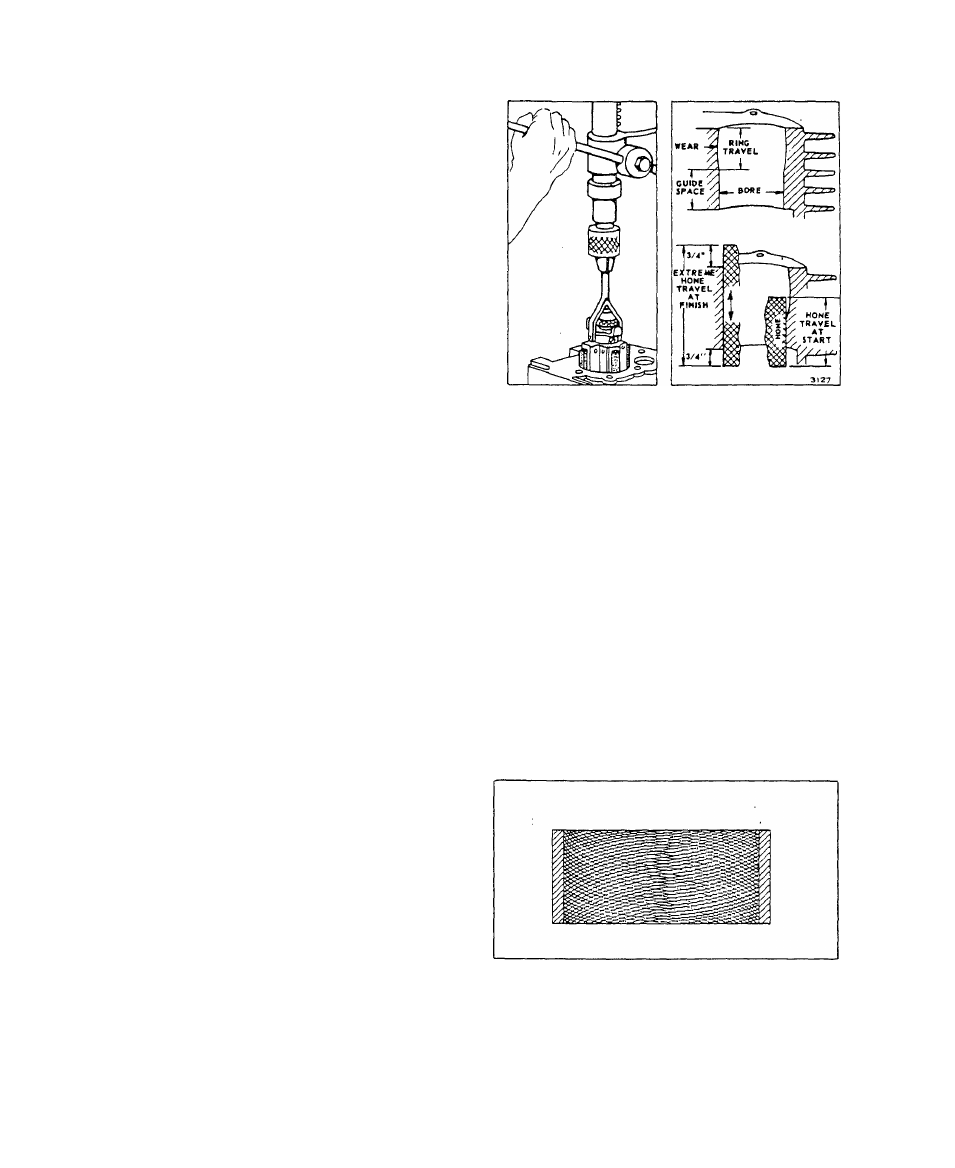

Fasten cylinder to honing plate.

Use a level to align drill press

spindle with bore. Oil surface of

drill press table liberally. Set

plate and cylinder on drill press

table. DO NOT ANCHOR TO TABLE. If

using portable drill, set plate

and cylinder on floor. Install

hone drive shaft into chuck of

drill press or portable drill. In

sert hone into cylinder. Connect

drive shaft to hone and.set stop

on drill press so that hone can

extend only 3/4 inch to 1 inch

from top or bottom of cylinder.

If using a portable drill, set a

wood block inside cylinder as a

stop for the hone.

With hone in center of cylinder bore, tighten adjusting knob until

stone fits snugly against cylinder wall. DO.NOT FORCE. Hone should

run at 300 to 700 rpm. Lubricate hone as previously recommended.Be

sure that cylinder and hone are centered and aligned with drive

shaft and drill spindle. Start the drill. As the hone spins, move

it up and down at lower end of cylinder, (Cylinder is probably not

worn at bottom, but will guide the hone to straighten the bore.)

As bottom of cylinder enlarges, gradually increase stroke lengths

until hone travels full length of cylinder bore. DO NOT EXTEND HONE

MORE THAN 3/4 to 1 INCH AT EITHER END OF CYLINDER BORE. As cutting

tension decreases, stop hone and tighten adjusting knob. Check the

cylinder bore diameter frequently with an accurate micrometer. Hone

about 0.0005 inch larger than required to allow for shrinkage when

cylinder cools. When within 0.0015 inch of desired size, change

from rough stone to finishing stone.

CYLINDER FINISH AND CLEANER

The finished cylinder wall should

have a crosshatch appearance, as

illustrated at right. This will

permit proper lubrication and ring

break-in.

After

honing,

clean

entire

cylinder

thoroughly

with

a

brush,

soap

and hot water. Do NOT use kerosene or gasoline - solvents of this

type will not remove all of the honing grit.

1 1 . 2

Issued 4-78