Process limits menu – Dukane DPC II Plus 9001:2000 User Manual

Page 99

89

Dukane Manual Part No. 403–566–01

Section 8 – Process Limits Menu

Process Limits Menu

The Process Limits Menu allows you to define

upper and lower bounds for suspect parts or for

bad parts. The limits are available in both units

of time and units of energy depending upon the

welding method chosen in Process Control setup.

In addition, if a dual–pressure welding method

is selected, total time and/or total energy limits

are also available for suspect or bad parts. The

same memory location is used for suspect and

bad part limits. The difference is that exceeding

a bad part limit terminates the weld cycle. Ex-

ceeding a suspect limit allows the weld cycle to

continue until it finishes normally or exceeds a

Total limit. There are 12 different limit settings

which are broken down as follows:

1a. There are two possible

BAD

PART

UPPER

TIME

LIMITS

(one for each pressure level).

1b. There are two possible

BAD

PART

UPPER

ENERGY

LIMITS

(one for each pressure level).

1c. There is one

TOTAL

BAD

PART

UPPER

TIME

LIMIT

and one

TOTAL

BAD

PART

UPPER

ENERGY

LIMIT

.

This makes a total of six

BAD

PART

UPPER

LIMITS

.

2. There are six

BAD

PART

LOWER

LIMITS

.

During a dual–pressure mode welding cycle how-

ever, only six of the limits (eight in mixed mode)

are applicable. In single pressure mode, this drops

to two usable limits at any one time since the

totals are available only in dual mode. For ex-

ample, you can set both upper time and energy

limits, but only the upper time limit is recognized

in the weld by time mode.

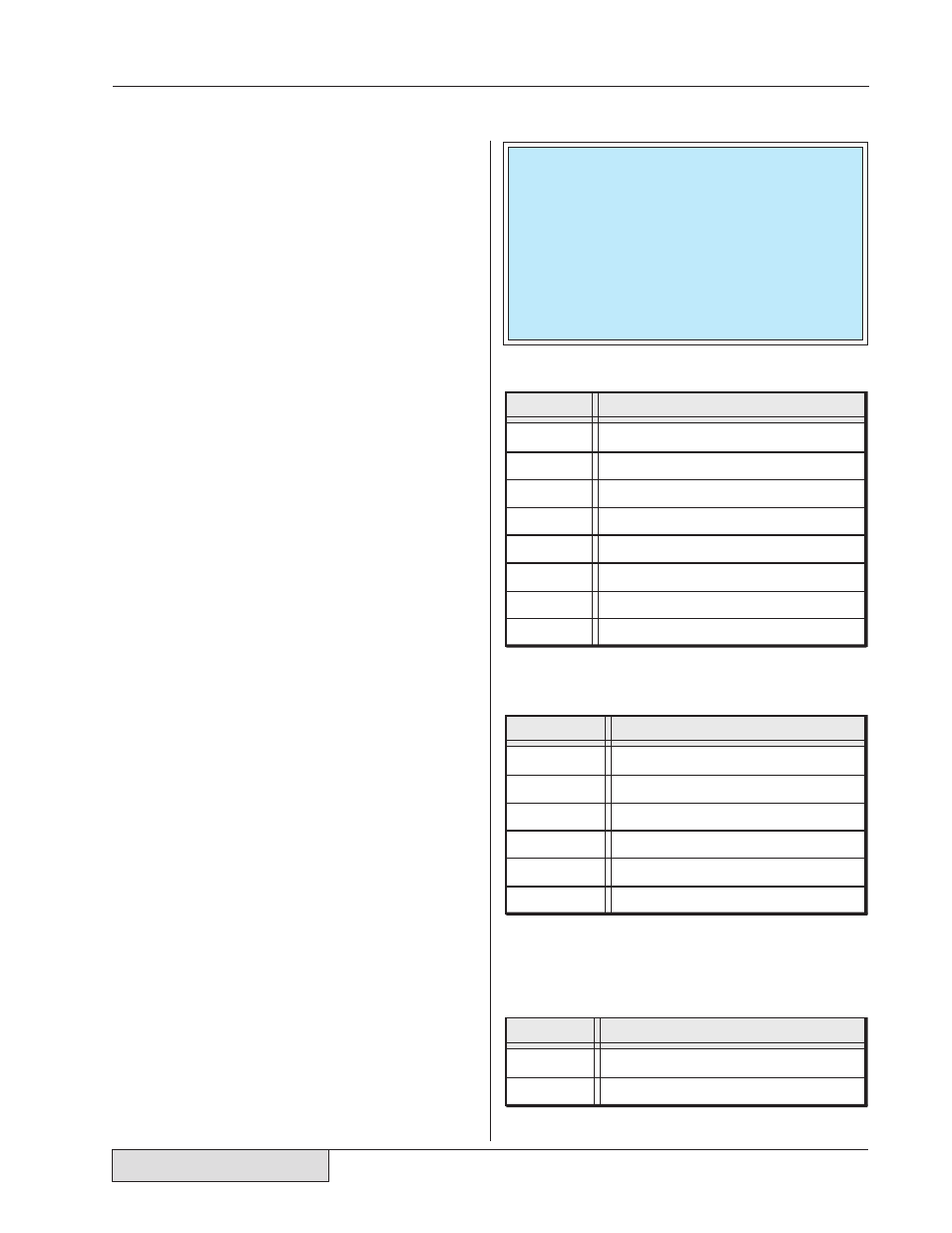

Table 8—I summarizes the 8 limits recognized in

a dual–pressure, mixed–mode welding cycle.

Table 8—II summarizes the 6 limits recognized in

a dual–pressure, uniform–mode welding cycle.

Table 8—III lists the 2 limits recognized in a single–

pressure welding cycle.

A Bad Parts Counter is also available in the Utili-

ties menu which is covered in the next section.

Cycle State

Parameter Limit Type

P1 T(E)

U

P1 Upper T

IME

(E

NERGY

) Limit

P2 Upper E

NERGY

(T

IME

) Limit

Total Upper T

IME

Limit

Total Upper E

NERGY

Limit

P1 Lower T

IME

(E

NERGY

) Limit

P2 Lower E

NERGY

(T

IME

) Limit

Total Lower T

IME

Limit

Total Lower E

NERGY

Limit

P2 E(T)

U

Total T

U

Total E

U

P1 T(E)

L

P2 E(T)

L

Total T

L

Total E

L

Cycle State

Parameter Limit Type

P1 T(E)

U

P1 Upper T

IME

(E

NERGY

) Limit

P2 Upper T

IME

(E

NERGY

) Limit

Total Upper T

IME

(E

NERGY

) Limit

P1 Lower T

IME

(E

NERGY

) Limit

P2 Lower T

IME

(E

NERGY

) Limit

Total Lower T

IME

(E

NERGY

) Limit

P2 T(E)

U

Total T(E)

U

P1 T(E)

L

P2 T(E)

L

Total T(E)

L

Cycle State

Parameter Limit Type

P1 T(E)

U

P1 Upper T

IME

(E

NERGY

) Limit

P1 Lower T

IME

(E

NERGY

) Limit

P1 T(E)

L

Table 8—

I

Recognized Limits in a Dual–Pressure

Mixed–Mode Welding Cycle

Table 8—

II

Recognized Limits in a Dual–Pressure

Uniform–Mode Welding Cycle

Table 8—

III

Recognized Limits in a Single–Pressure

Welding Cycle

DEFINITION

A

mixed

mode is a dual–pressure weld cycle in

which one unit of measurement (e.g. time) is

used for Pressure 1 and the other unit of mea-

surement (e.g. energy) is used for Pressure 2.

A

uniform

mode is a dual–pressure weld cycle in

which the same unit of measurement (e.g. time)

is used for both Pressure 1 and Pressure 2.