Removing the mounting stud from a horn or booster, Removing replaceable tips from a horn – Dukane DPC II Plus 9001:2000 User Manual

Page 123

113

Dukane Manual Part No. 403–566–01

Section 10 – Probes and Probe Stracks

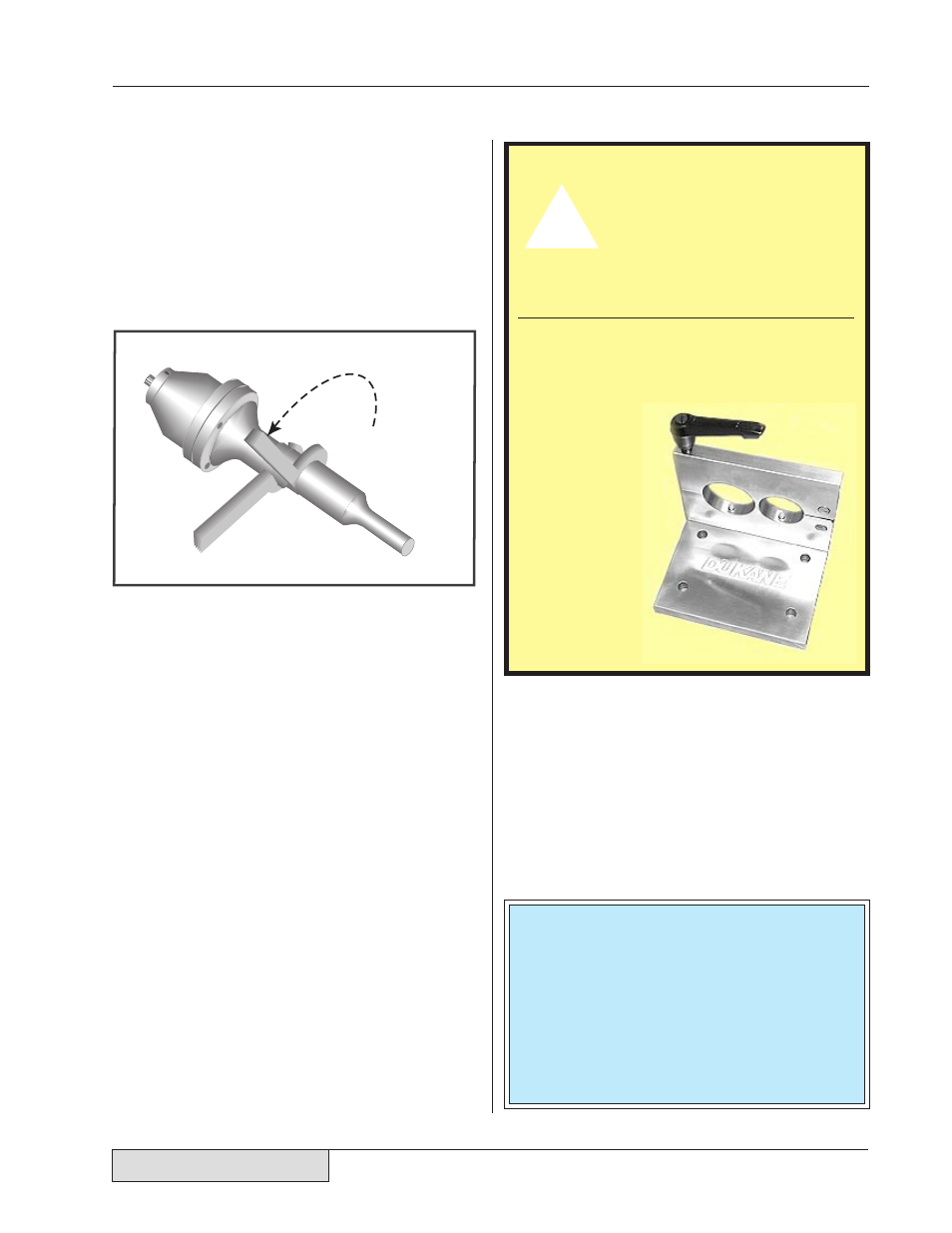

Separating The Horn From A

Booster, Booster From A

Probe Or Horn From A Probe

On all transducers and horns with spanner wrench

holes (see Figures 10–8), use only the correct size

spanner wrench that came with your system to pro-

vide sufficient torque to loosen a joint.

On boosters and horns with wrench flats, use only

the correct size wrench to provide sufficient torque

to loosen a joint when necessary.

Removing The Mounting Stud

From A Horn Or Booster

Only use an allen wrench of the correct size in the

socket head of stud to remove the stud from the

horn or booster.

Removing Replaceable Tips

From A Horn

Use an open end wrench of the correct size to fit

the wrench flats of the detachable tip. Use a span-

ner wrench (on horns with spanner wrench holes)

or an open wrench (on horns with wrench flats) to

provide an opposite force and keep the horn from

turning in your hand. Refer to Figure 10–9 for the

correct tip removal procedure.

Loosen

Figure 10–8

Seperating The Horn From The Booster

NOTE

Do not hold a booster by the mounting rings

when removing the stud from the booster. Use

a spanner or open–end wrench to provide op-

posite force and keep the horn or booster from

turning in your hand when loosening the stud.

Use a spanner wrench on horns and boosters

with spanner wrench holes. Use an open end

wrench on horns and boosters with wrench flats.

ƽ

CAUTION

NEVER clamp a horn or

booster in a vise. The re-

sulting scratches or

gouges in the surface are

stress risers which may re-

sult in cracks.

Dukane has a stainless steel tool vise (Part

No.UFTV20) for clamping 20kHz boosters

and transducers to facilitate disassembly of

stubborn com-

ponents with-

out damage. It

accepts front

slug and

booster tool-

ing diameters

of 1.5 and

1.81 inches

and has re-

placeable anti-

rotation pins.