Stack assembly, Attaching a replaceable tip to a horn – Dukane DPC II Plus 9001:2000 User Manual

Page 117

107

Dukane Manual Part No. 403–566–01

Section 10 – Probes and Probe Stracks

Stack Assembly

Attaching A Replaceable Tip

To A Horn

1. Inspect all horn and tip surfaces for stress

cracks, chips, or gouges. Any of these irregu-

larities will affect operation and could lead to

further equipment damage. Contact the Du-

kane Ultrasonics Tooling Department concern-

ing damaged horn components.

2. Apply an extremely thin layer of a high tem-

perature, high pressure silicon grease to the

back surface that mates with the horn. The

grease will allow both surfaces to intimately

mate and become acoustically transparent

which improves the energy transfer. Do not

apply any grease to the threads. We recommend

Dow–Corning #4 (or #111 as an alternate). A

small packet of Dow–Corning #4 is supplied

with the system. If you cannot use a silicon–

based grease in your facility, a petroleum–

based grease may be used. However, it is likely

to leave carbonaceous deposits on the surface,

and require more frequent joint maintenance.

Failure to follow these instructions, may re-

sult in the mating surfaces bonding and diffi-

culty removing the tip from the horn.

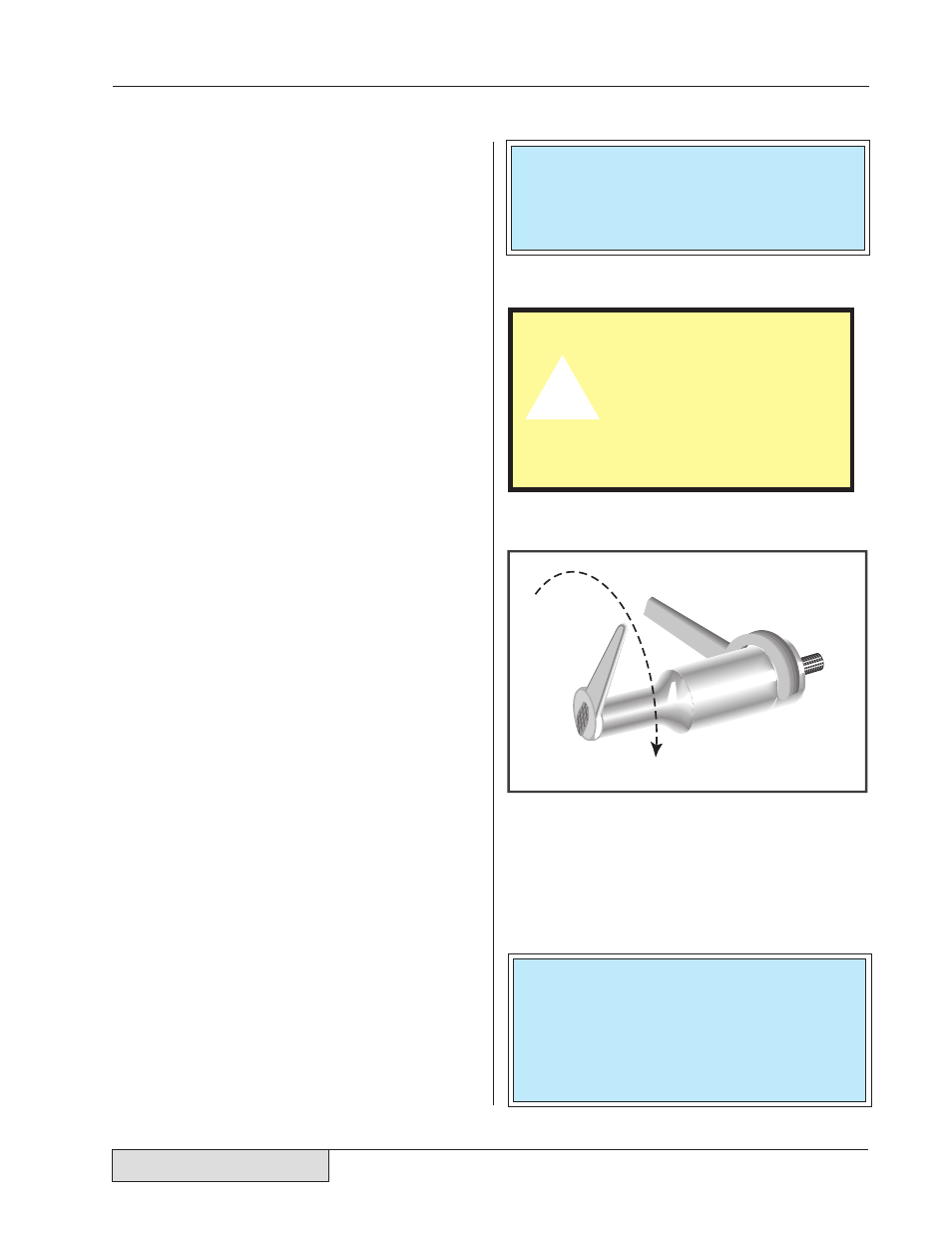

3. Thread the tip into the horn and tighten to the

torque specifications below using an open end

wrench of the correct size to fit the wrench

flats of the tip. This is illustrated in Figure 10–

3. If necessary, use a spanner wrench (on horns

with spanner wrench holes) or an open end

wrench (on horns with wrench flats) to keep

the horn from turning in your hand. A canvas

strap wrench is permissible if it does not gouge

or scratch the horn.

•

70 inch-lbs for an 8mm threaded tip

•

100 inch-lbs for a 3/8" x 24 threaded tip

•

160 inch-lbs for a 1/2" x 20 threaded tip

Tighten

Figure 10–3

Replaceable Tip Installation

CAUTION

NEVER clamp the horn

in a vise. The resulting

scratches or gouges in

the surface are stress

risers which may result

in cracks.

ƽ

NOTE

Dukane Part No for the 20kHz spanner

wrenches is 721–68

Dukane Part No for the 40kHz spanner

wrenches is 721–44

NOTE

Do not apply any grease to the threads of the

replaceable tip. This may cause the tip to loosen

from the horn resulting in inconsistent operation.