Auto stop disable enable, Auto stop, Ground detect – Dukane DPC II Plus 9001:2000 User Manual

Page 78: Mpc probe, Enable, Trigger method, Auto, Stop option, And for a parameter called scrub time ( t, And press

68

Dukane Manual Part No. 403–566–01

DPC

™

II Plus and EZ Welder System – User’s Manual

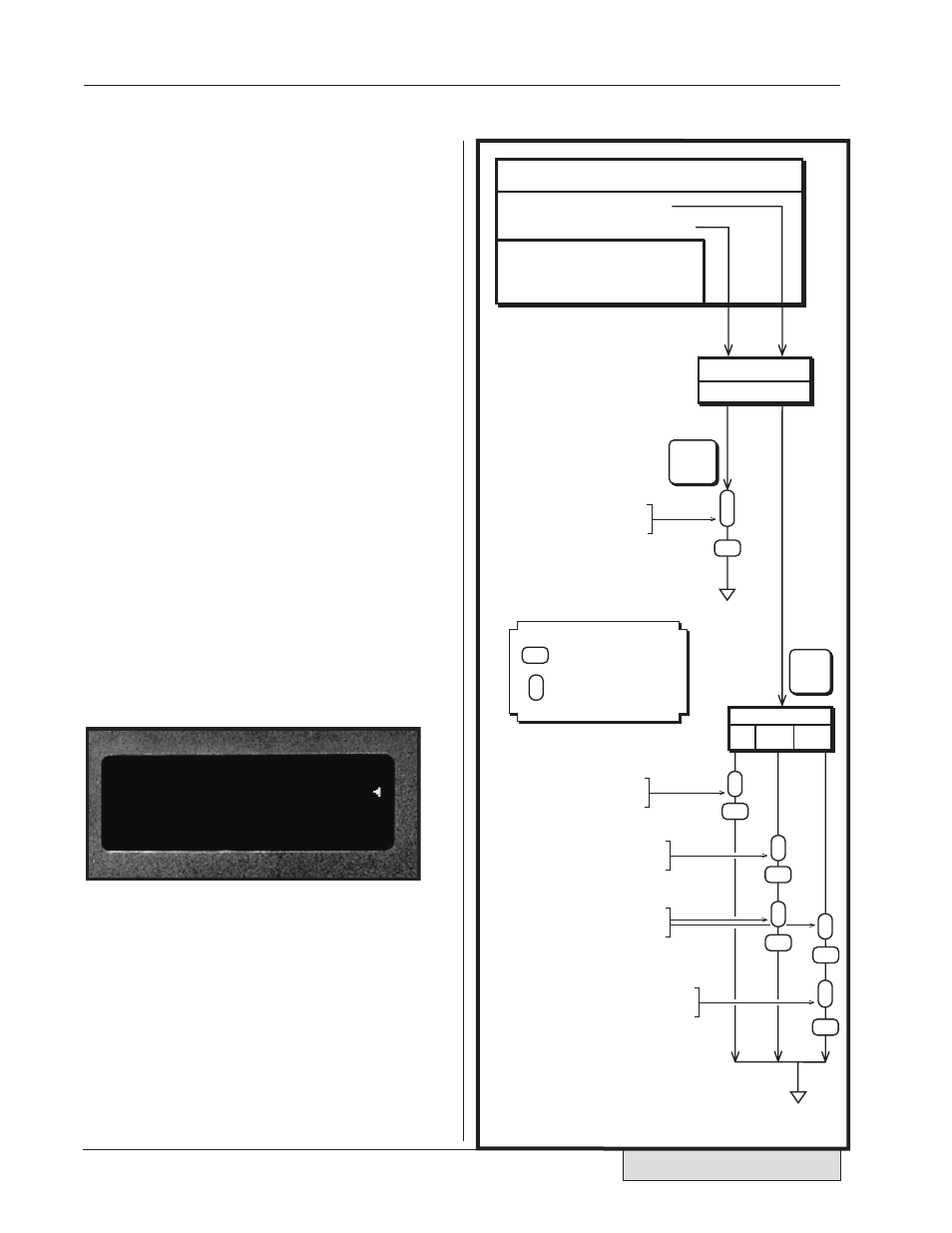

MPC Probe

The cable connection diagram for connecting the

Multi–Probe Controller module is shown in Sec-

tion 3 in Figure 3–6. The flow chart for the Pro-

cess Control menu with a Multi–Probe Controller

installed is shown in Figure 7–12. If you do not

have a Power Output module installed, the Energy

Weld Method menu will not be displayed.

The Multi–Probe Controller (MPC) flow chart

adds three options to the basic Hand Probe flow

chart shown in Figure 7–7.

1. An

AUTO STOP

option is included which can

be enabled or disabled.

2. A delay time value (T

delay

) can be entered for

untimed operation.

3. A weld method called

GROUND DETECT

is now

available. This method requires values to be

entered for the maximum weld time (T

max

) and

for a parameter called scrub time (T

scrub

).

AUTO

*

STOP Option

This menu is shown in Figure 7–13. To use this

option, move the SH704 jumper block to JU715

(see Figure 5–12). Use the down arrow key to se-

lect

ENABLE

and press

ENTER

to continue.

When Auto Stop is enabled, a signal on pin 9 of the

HD–15 SYSTEM IN connector will be recognized.

This permits external automation equipment to stop

the welding cycle. If Auto Stop is set to disable, then

the signal will be ignored. If the SH704 jumper block

is left in the End–Of–Weld factory default position

(JU716), only the welding is stopped. Any pro-

grammed Hold or Afterburst (discussed later) will

still be executed regardless of the Auto Stop mode.

AUTO STOP

DISABLE

ENABLE

UNTIMED MPC PROBE

ENABLE or DISABLE

AUTO STOP

TIMED

MPC

PROBE

UNTIMED

MPC

PROBE

WELD METHOD

TIME ENERGY

GND.

DETECT

TRIGGER METHOD

TIMED MPC PROBE

RTW

RTW

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

T

we

ld

E

we

ld

T

max

T

max

T

scrub

T

dela

y

T

we

ld

RTW = Ready To Weld

LEGEND

= Front Panel ENTER Key

(Section 4.3 – Menu Keys)

ENTER

= Parameter Value Entry

T = Time

E = Energy

Maximum

E

weld

Minimum

E

weld

= 12,000 Joules

= 1 Joule*

Maximum

T

max

Minimum

T

max

= 30.000 Seconds

= 0.001 Second*

Maximum

T

weld

Minimum

T

weld

= 30.000 Seconds

= 0.001 Second*

Maximum

T

delay

Minimum

T

delay

= 30.000 Seconds

= 0.000 Second

Maximum

T

scrub

Minimum

T

scrub

= 0.150 Seconds

= 0.001 Second

* These values can be set to zero, but will not produce any

output. The values listed represent the resolution and are

the smallest values that will produce any output signal.

Figure 7–12

Multi–Probe Controller Flow Chart

Figure 7–13

MPC Probe Auto Stop Mode Menu

* AUTO refers to Automation not automatic