Bevel lock, Carriage bearings, Arm and column – Sears 113.197611 User Manual

Page 77: Miter lock, Maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Maintenance

Bevel Lock

If the motor can be moved by hand when

the bevel lock is locked, if the lock offers

little resistence when being locked, or if

the space between the lock lever and cast

ing is different from approximately

V i b ,

adjust according to step 10 in Mount

Motor section of Assembly.

Carriage Bearings

The carriage should roll freely but with

some resistance for the entire length of

travel. If the carriage moves too freely or

with too much resistance, adjust the bear

ings according to the instructions in Align

ment and Adjustment.

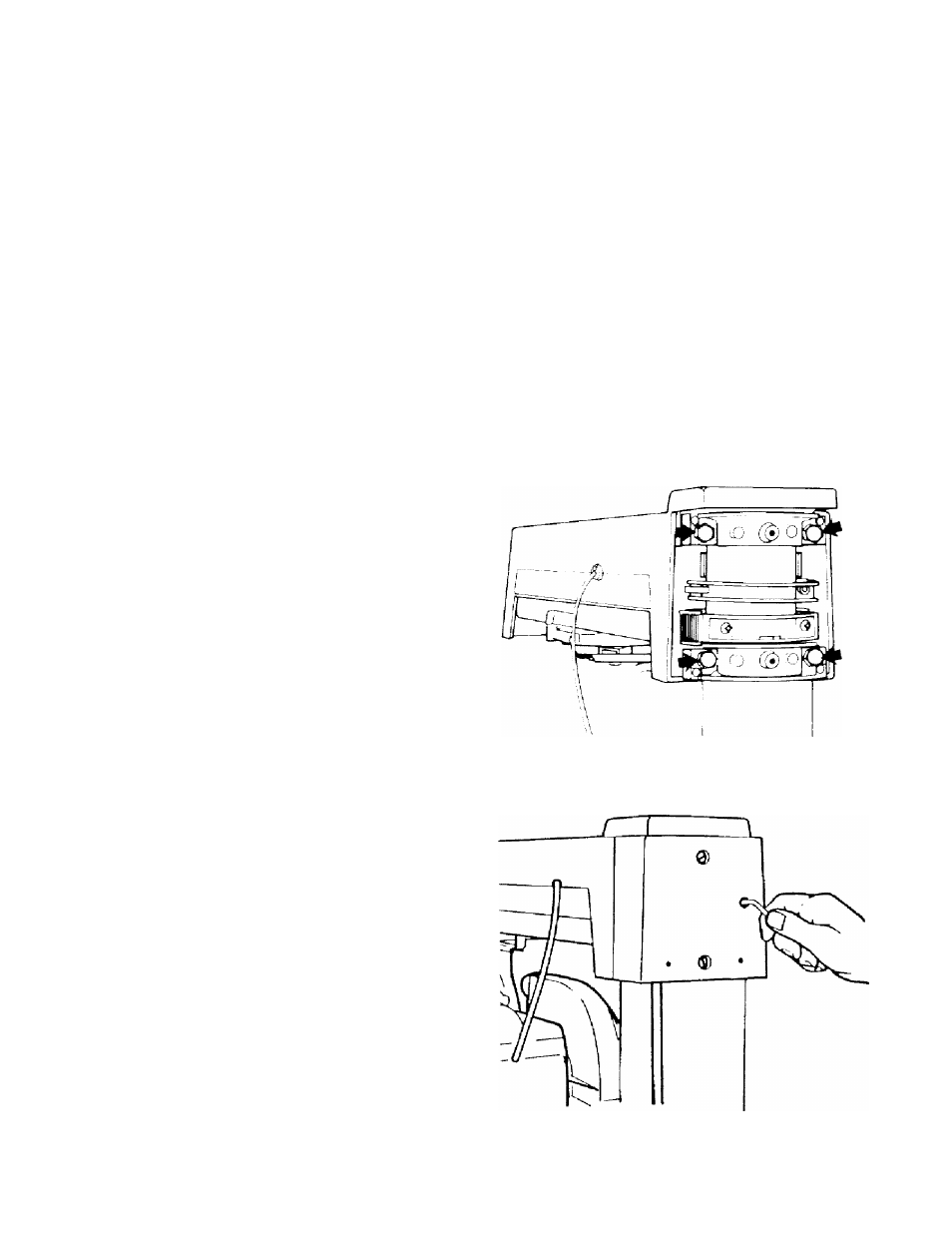

Arm and Column

If you can move the end of the radial arm

up and dow'n w'hen the arm is unlocked bc-

tw'ecn

0

and 45° miter, adjust:

1

. Remove rear arm cover.

2

. Evenly tighten top two hex head tap

ping screws, then tighten bottom two hex

head screws, but not as tightly as the top

ones.

3. Re-install rear arm cover.

Miter Lock

If the radial arm caji be moved side to side

by hand when locked between

0

and

4 5

°

miter, adjust:

1

. Unlock miter lock and move radial arm

to any non-indexed position.

2. Tighten socket cap screw, in rear of

arm cover, one quarter turn.

3. Lock miter lock and try to move radial

arm. If arm still moves, slightly tighten

socket cap screw. If lock is too difficult to

lock, slightly loosen socket cap screw.

77