Adjust carriage bearings, Miiqnrngni anci mujuslitieni – Sears 113.197611 User Manual

Page 44

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

I S

Jb

.^ml

^¡i^l ■ ■ W Jb ^N

b

MIIQnrnGni anCi MujUSliTieni

11

^

s

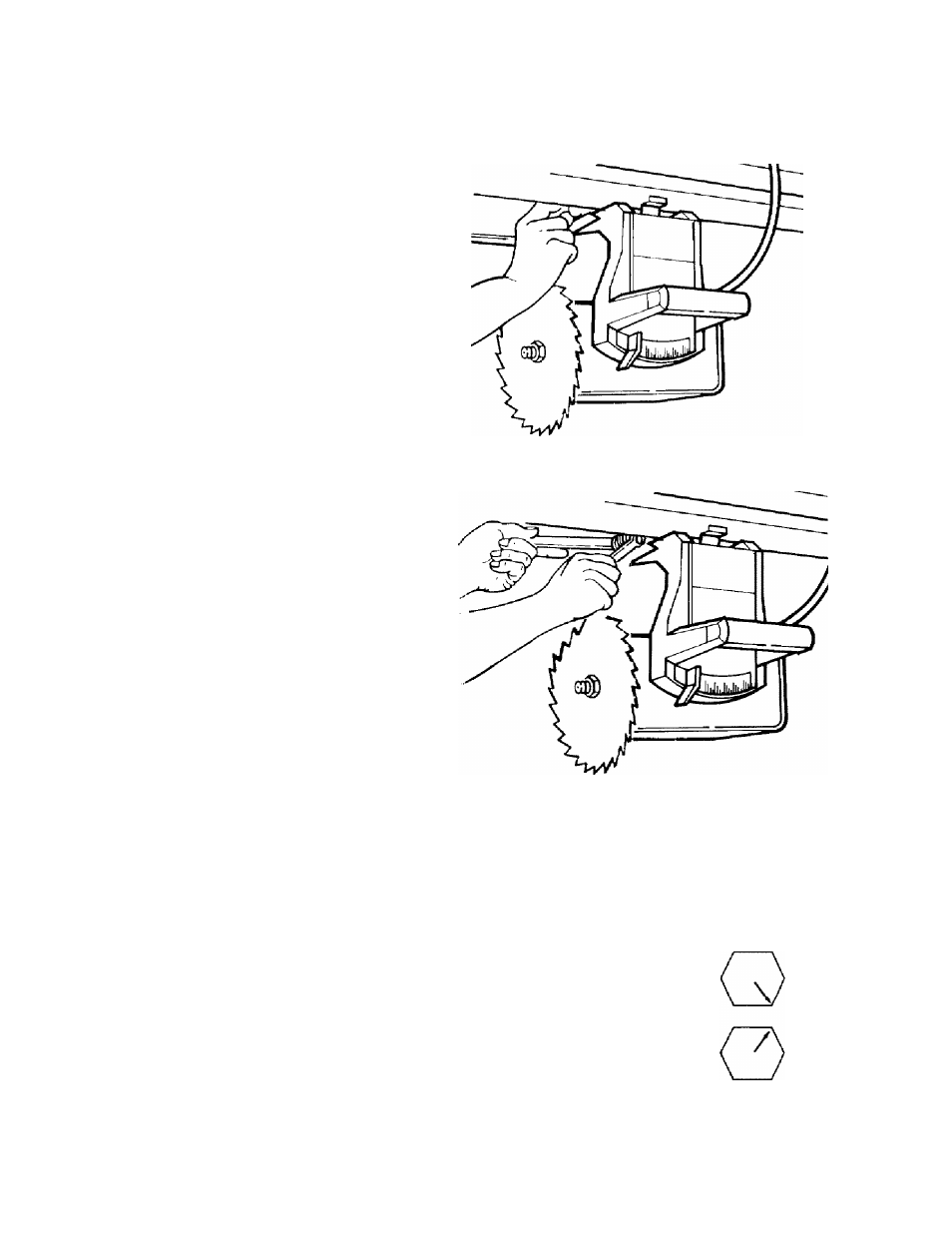

Adjust Carriage Bearings

The goal of this adjustment is to eliminate

looseness between the carriage bearings

and the radial arm. The blade carriage

should roll freely along the entire length

of the radial arm, but with some resistance.

1. With blade still locked in out-rip posi

tion, unlock rip lock and move blade car

riage to rear as far as it will go.

2. From front of saw, look up under

radial arm to identify front carriage bear

ing. With thumb and index finger, get

pinch-hold inside groove of bearing.

Apply force to bearing and at same time,

pull blade carriage forward. Force should

not

stop bearing from turning while car

riage is moving.

3. If you can stop bearing from turning

while carriage is moving, adjust bearings:

i) position blade carriage for good access

to front and rear bearings

ii) lock rip lock

hi) hold front bearing bolt in place and

loosen nut

iv) rotate bolt a few degrees, then tighten

nut.

Note:

Carriage bearings have eccentric

bolts. High side of each bolt is marked by

an arrow. Adjust rear carriage bearing

same amount, but in opposite direction, as

you adjust front carriage bearing.

Note:

Do not overtighten. Overtightening

can cause blade carriage to move with dif

ficulty and will reduce life of track and

bearings.

4. Before proceeding to next section,

repeat steps to Square Blade to Table for

Ripping, because adjusting carriage bear

ings affects that alignment.

\

\

OK

____ / Both Arrows Point Up

/

\

OK

/ j

Both Arrows Point Down

'

\ WRONG

/

)

One Arrow Points Up

■vl----/ One Arrow Points Down

44