Square blade to table for ripping, Alignment and adjustment – Sears 113.197611 User Manual

Page 43

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Alignment and Adjustment

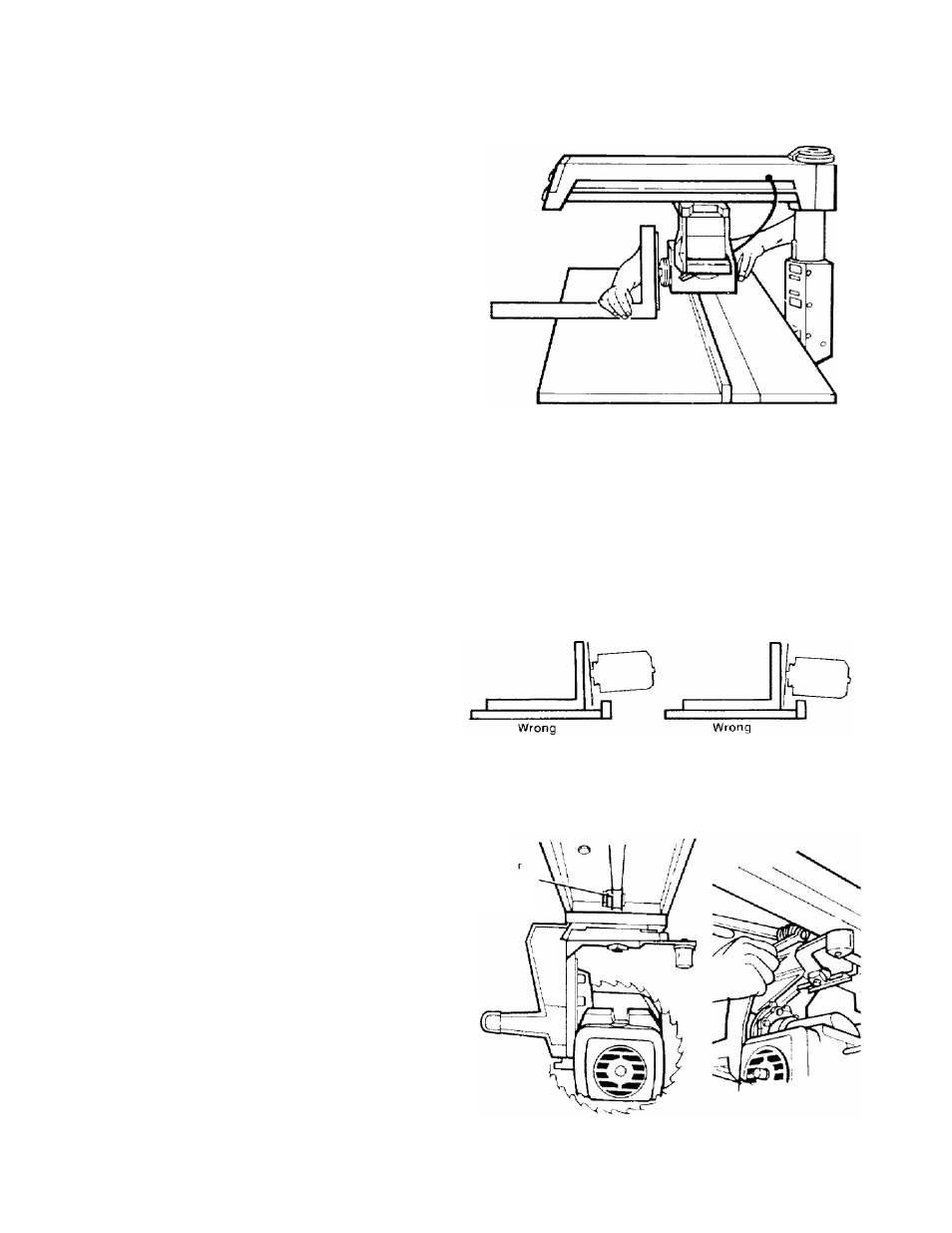

Square Blade to Table for Ripping

The goal of this adjustment is to make the

blade perpendicular to the table so that

rip cuts will be accurate; otherwise all rip

cuts will have a slight bevel angle.

1

. Ixtck blade in out-rip position (blade

towards table front, motor towards

column). Lock rip lock.

2. Raise radial arm to allow clearance for

square.

3. Place square so long edge is on table

and short edge is against blade (not on a

tooth), beside blade collar.

4. There should be no gap between blade

and square. Note:

Not all blades are per

fectly flat. Check different points along

blade surface by making quarter turns and

looking for gap each time. Consider overall

fit of blade.

If there is no gap, no adjust

ment is needed.

fV

Motor

n

Í]

Correct

5. If there is a gap, adjust rear carriage

bearing (which is visible when you go to

rear of saw and look up under radial arm-

carriage bearing rides on central track):

i) hold bolt in place and loosen nut on

bearing

ii) rotate bolt until gap closes

iii) hold bolt in place and tighten nut.

6

. Re-check alignment and adjust as

needed.

Rea

Carriage

Bearing

43