Ripping set-up procedure, A warning, Ripping – Sears 113.197611 User Manual

Page 66

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

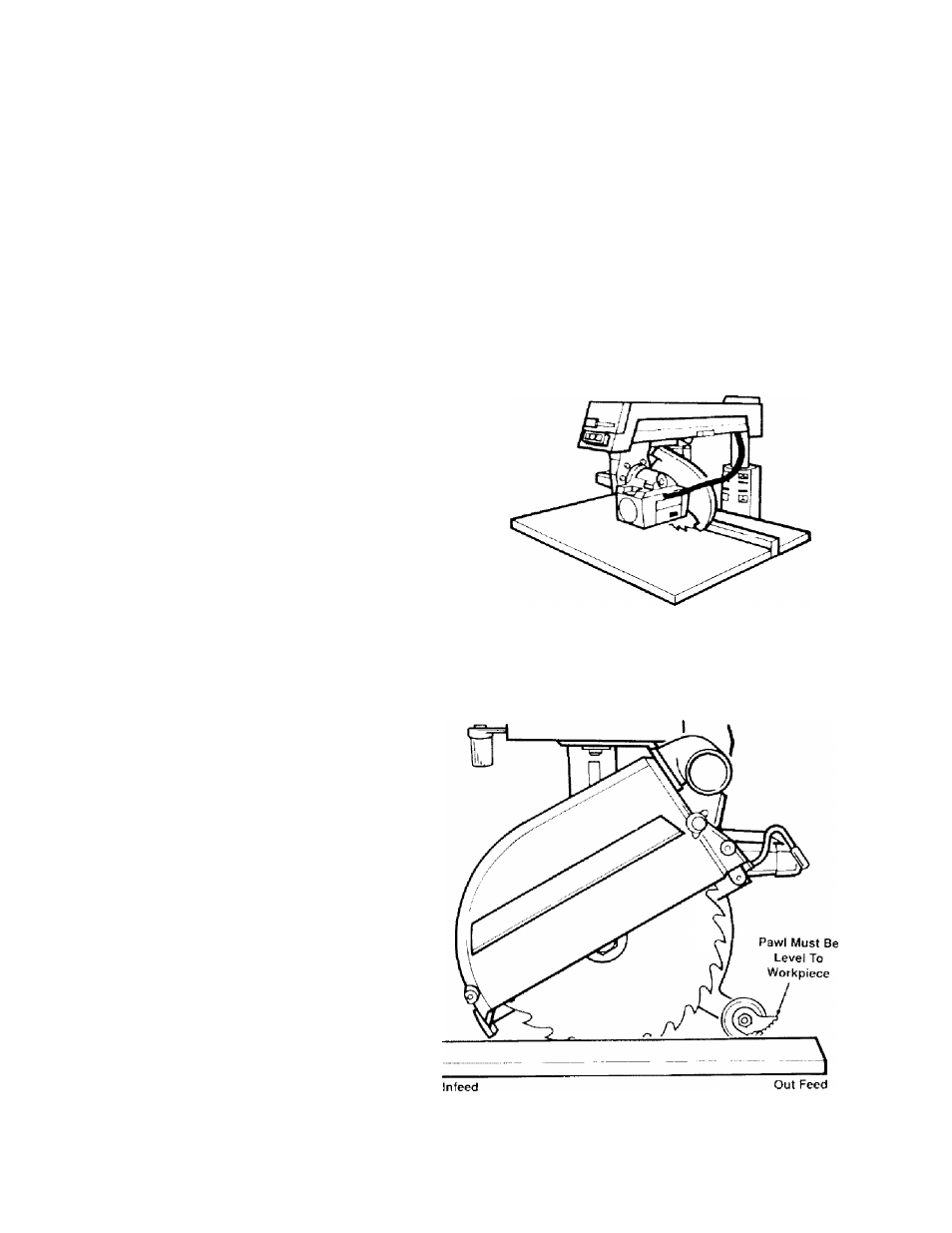

Ripping

Ripping Set-up Procedure

Follow these steps

before

ripping.

These

steps must be repeated each time a dif

ferent thickness workpiece is ripped.

A

kerf must be made for each different

width cut.

1.

Prepare table:

-insert solid (no kerfs) fence

(Note:

Use

auxiliary fence when blade is set

1/2

to 2"

from fence)

-lock table locks.

2. Prepare blade:

-lock radial arm at

0

” miter

-lock motor at desired bevel angle

-lock blade in in-rip position*

-lower blade to just clear table

-lock blade carriage desired distance

from fence.

Make sure widest part of

workpiece will he between blade and fence.

*iise out-rip position only when blade is

set

12

” or more from fence

3. Make kerf:

i) turn saw on

ii) lower blade about

Vie"

into table

iii) turn saw off and remove yellow key.

4. Place workpiece parallel to and up

against blade.

Note:

Workpiece will he be

tween blade and table front.

5. Low'er guard nose until it just clears

top surface of workpiece, then tighten

guard clamp screw.

6

. Lxtwer pawls and spreader so spreader

hangs along side of workpiece, in line

with blade, and one set of pawls rests

level on workpiece surface, then tighten

pawls/spreader wing nut.

7. Test setting: push workpiece toward

outfeed side to see that workpiece moves

freely; push workpiece toward infeed side

to see that pawls grab.

If these conditions

are not met, re-set pawls until they are.

A

WARNING

If workpiece is pushed along fence

with kerfs, workpiece could get

caught on kerf, pinch blade and

c a u s e k i c k b a c k . D o n o t u s e

crosscutting fence for ripping.

66