Air brake, Routing the air brake cable and air hose – Dynojet 250iPX: Installation Guide User Manual

Page 85

A C C E S S O R I E S

Air Brake

Version 2

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

3-3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AIR BRAKE

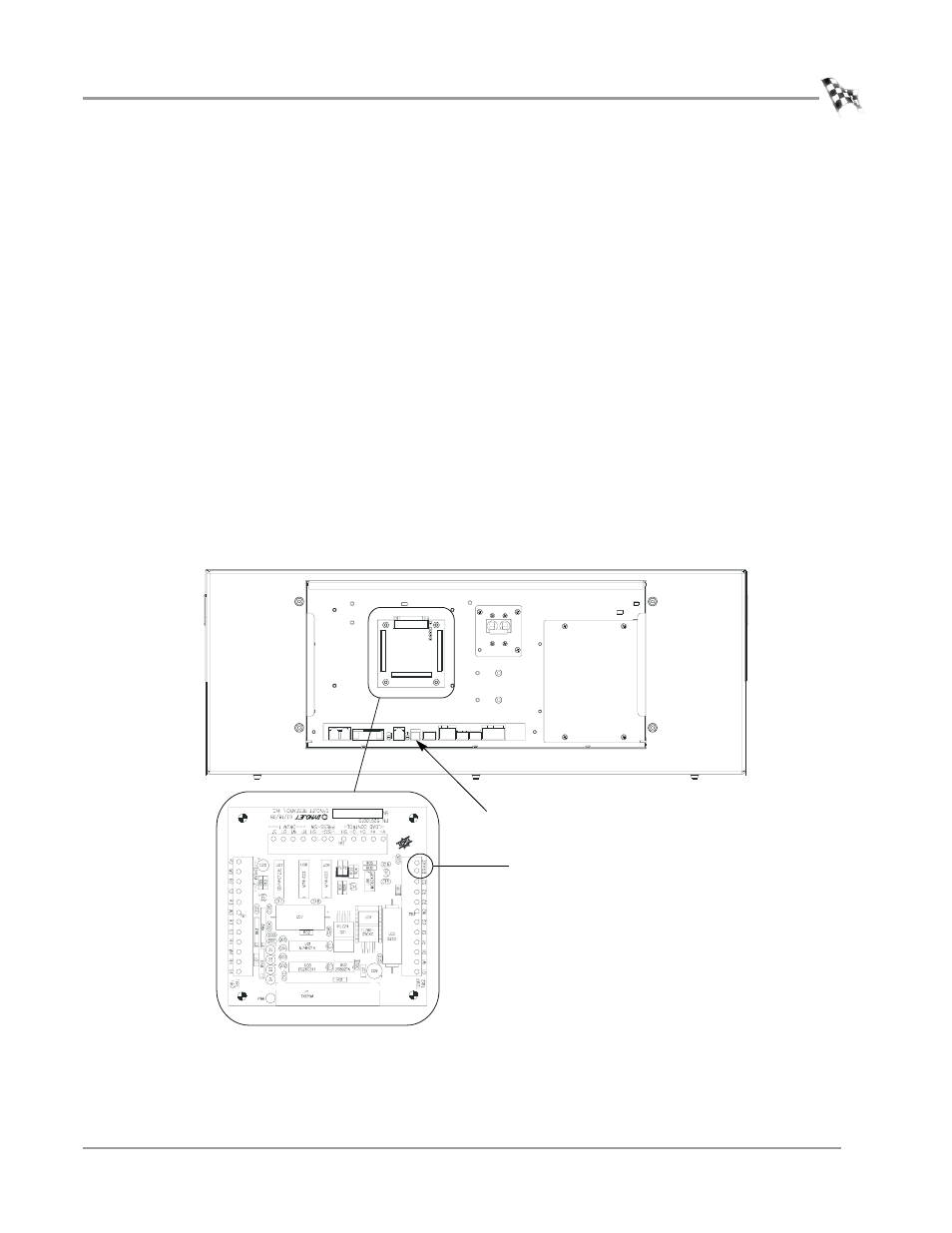

The optional air brake (P/N 63920005) comes installed and ready to use. You will

need to provide an air hose nipple (1/4-inch NPT) to connect your clean, dry shop air

supply (60 psi, 415 kilopascal, max constant line pressure) to the dynamometer. Once

air pressure is connected and the air brake cable is routed, the air brake is ready to

use.

Note: For information on installing the air brake, refer to the Air Brake and EEC

Kit Installation Guide for Model 200i/250i and 200iP/250iP Motorcycle

Dynamometer, P/N 98123114.

R

OUTING

THE

A

IR

B

RAKE

C

ABLE

AND

A

IR

H

OSE

1

Open the CPI front panel to access the breakers and Breakout board.

2

Route the air brake cable from the air brake solenoid to the CPI.

Note: The CPI end of the air brake cable splits in two.

3

Connect the cable with the two black wires to the Breakout board wiring block

labeled Brake.

4

Attach the 4-pin connector to port P7 on the CPI board.

Figure 3-2: Route the Air Brake Cable

PD149

P7 on the

CPI board

brake wiring block

on breakout board