Eddy current brake installation, Unpacking the eddy current brake – Dynojet 250iPX: Installation Guide User Manual

Page 31

I N S T A L L A T I O N

Eddy Current Brake Installation

Version 2

In Ground Model 200iPX/250iPX Motorcycle Dynamometer Installation Guide

2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EDDY CURRENT BRAKE INSTALLATION

This section will walk you through removing the eddy current brake (or retarder)

from the crate and attaching the brake to your dyno. To route and wire the

temperature sensor cable and the theta controller to the Breakout board refer to

“Routing the Eddy Current Brake, Battery, and Dyno Power Cables” on page 2-39 and

“Wiring the Breakout Board” on page 2-43.

You will need to provide equipment capable of lifting the eddy current brake off the

crate and into position in your dyno room. You will also need a pair of straps. Dynojet

recommends using continuous nylon loop style straps.

To prevent possible injury, unplug all power cords and disconnect the battery.

You will need the following parts:

• 62919004

Eddy Current Brake

• 37620622

Woodruff Key, 3/8 x 1-3/8"

• 62240070

Driveline Assembly

U

NPACKING

THE

E

DDY

C

URRENT

B

RAKE

1

Remove the four bolts securing the brake to the crate.

2

Remove the retarder connector plates, if present.

3

Place the ends of a nylon loop strap through the lifting eyes on either side of the

brake and hook onto the shaft.

4

Using a forklift, lift the eddy current brake from the crate and place the brake in

the pit near the drum module making sure not to hit the driveline assembly.

5

Record the eddy current brake number on the inside cover of this manual.

#

RECORD

Be sure you record the eddy current brake number on the inside cover of this

manual.

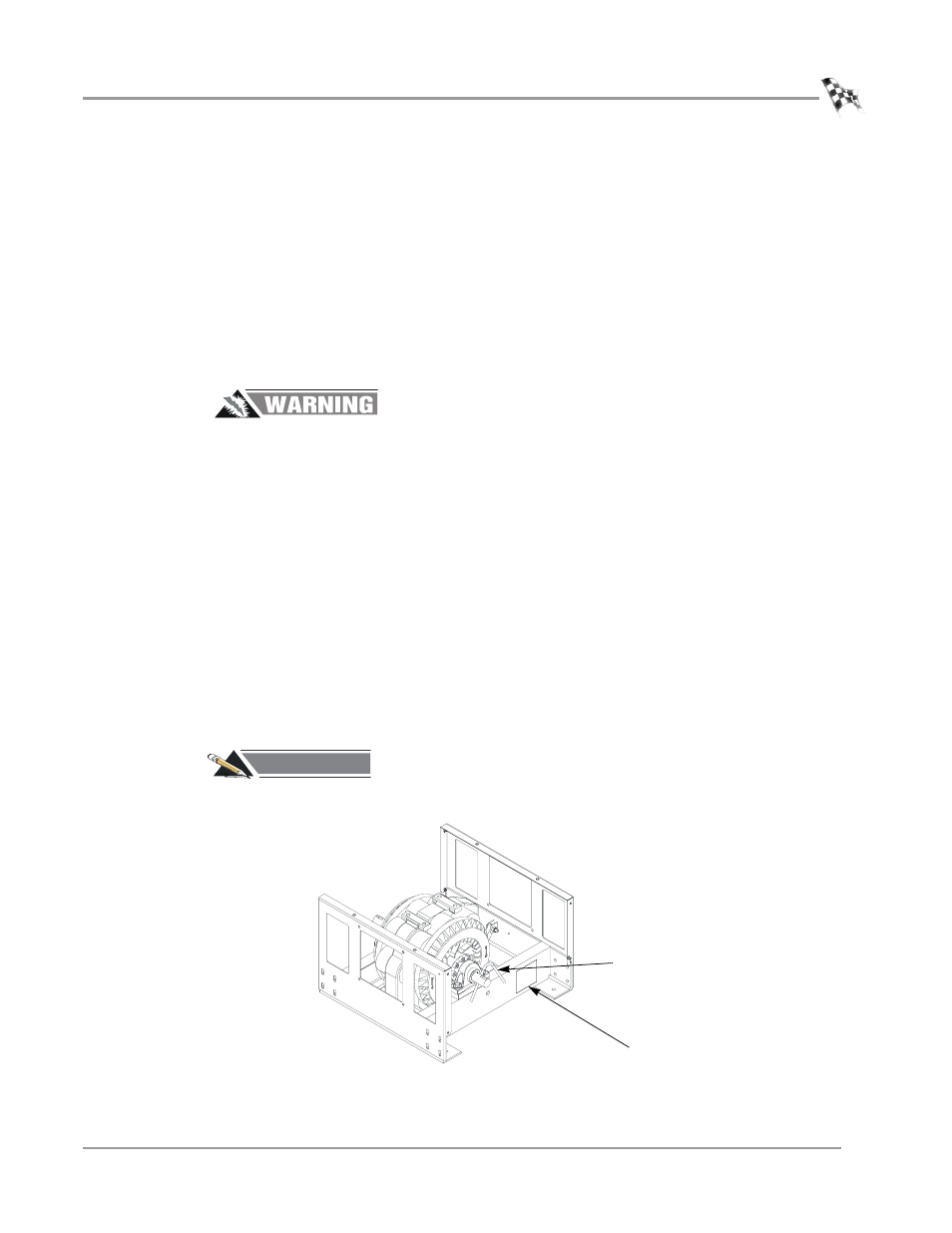

Figure 2-4: Record the Eddy Current Brake Number

eddy current brake number

lifting eye