Metrohm 789 Robotic Sample Processor XL User Manual

Page 115

3.8 Dosing and liquid handling

Metrohm Sample Processor, Operation

107

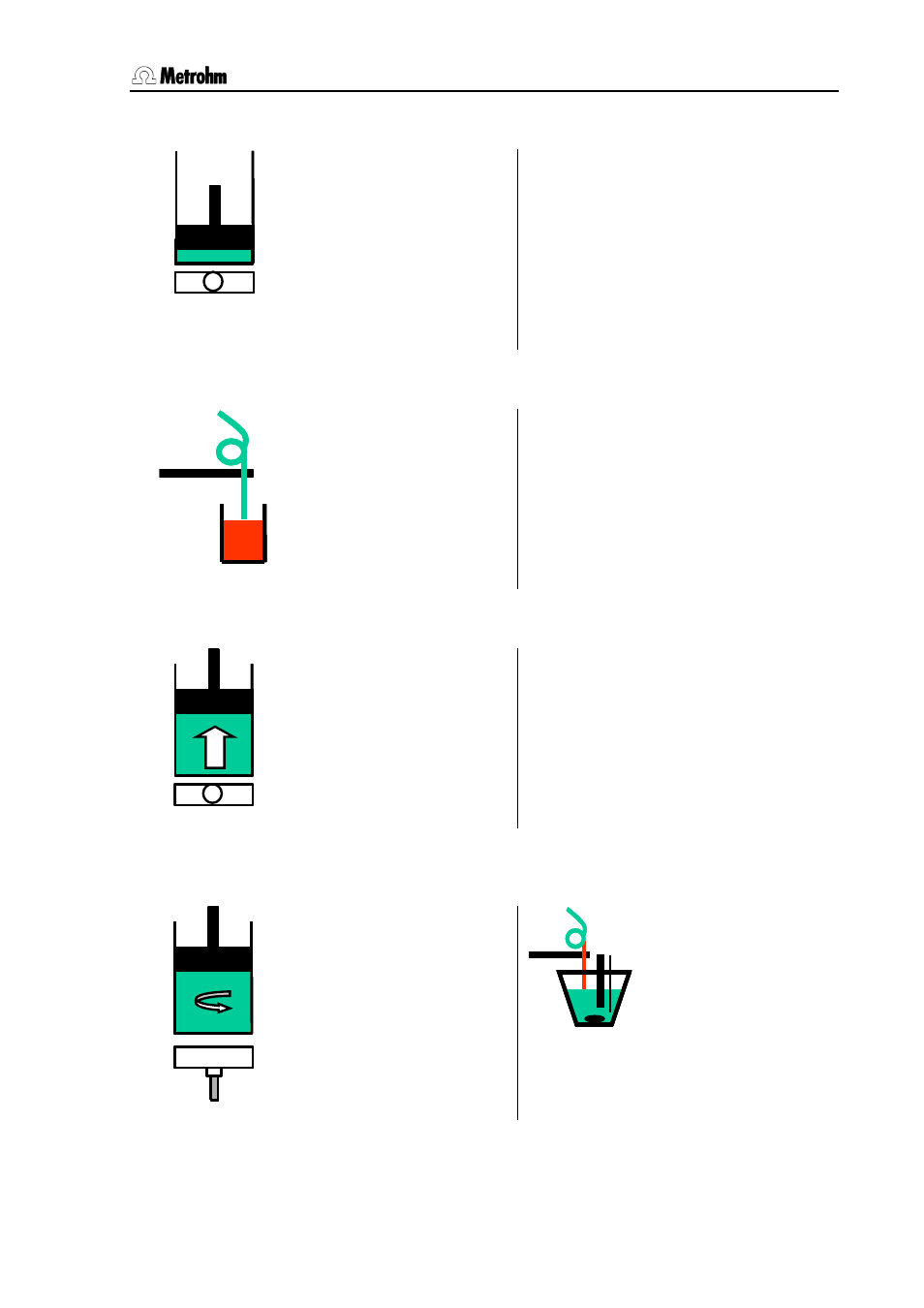

Formation of separating bubble (air gap)

11

Command sequence:

LIFT: 1 : shift mm

DOS: 1.1 : -0.5 mL

In order to prevent the carrier liquid and

sample solution from mixing a separating

bubble, must be formed that occupies a

length of at least 5 mm in the pipetting

tubing. However, the separating bubble

must also be measured out with sufficient

accuracy. This is why a Dosing unit with

max. 20 mL cylinder capacity should be

used for pipetting.

Move to sample

Command sequence:

MOVE: 1 : sample

LIFT: 1 : work mm

The (dissolved or liquid) samples can be

contained in open beakers on the rack or

in sealed vials. In the latter case instead

of the pipetting tubing a suitable injec-

tion needle should be connected to Dos-

ino Port 1 with a normal piece of tubing

(2 mm dia.).

Aspirate sample

11

Command sequence:

DOS: 1.1 : -5.0 mL

WAIT: pause 3 s

LIFT: 1 : shift mm

DOS: 1.1 : -0.2 mL

Aspiration of the sample should be car-

ried out at a reduced filling rate

(<10 mL/min). The appropriate setting

can be made under

>Dosing

unit def.

With non-aqueous samples an additional

small air bubble may be drawn into the

pipetting tip in order to prevent the sam-

ple solution from dripping.

Move to target

222

Before the pipetting tubing

containing the measured

out sample is moved, the

corresponding Dosino port

must be closed.

Command sequence:

DOS: 1.2 : port mL

MOVE 1 : ext.1

LIFT: 1 : work mm

The titration cell should

be filled with solvent

before the sample is

added so that the

sample can be pipet-

ted directly into the liq-

uid (tip immersed).