Bowers Group Sylvac D100S Readouts User Manual

Page 24

Following display:

-3

σ =

_

X - 3

σ = lower regulation or intervention limit

+3

σ =

_

X + 3

σ = upper regulation or intervention limit

-NG = number of stored values smaller than lower tolerance

+NG = number of stored values greater than upper tolerance

%Def = percentage of defective stored values =

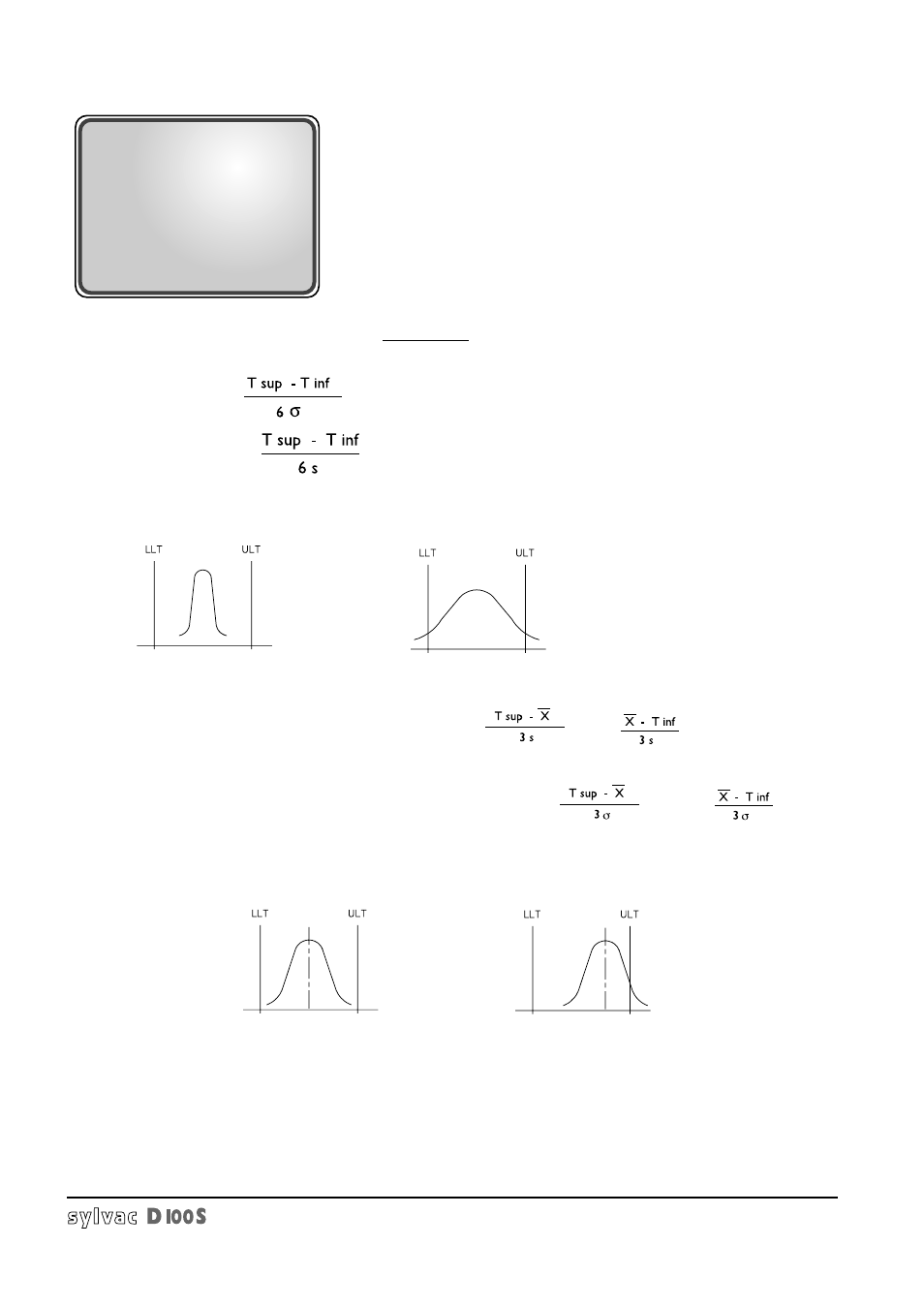

Cp = process capability =

Cm = machine capability =

s given for a sample at time t.

A high Cp will indicate a small dispersion of measured values inside the tolerances:

High Cp

Low Cp:

Cmk = center capability = the smaller value of the 2 formulas

and

Cpk = process capability in relation to spec mean = the smaller value of

and

Cmk/Cpk will formulate capability in a manner that indicates shifts (skewing) in the mean of the distribution away from

the midpoint:

Good Cmk/Cpk:

Poor Cmk/Cpk:

Cp >= 1.33 corresponds to a capable process

Note: some users require a Cp >= 1.66 which corresponds to 10.

These indices of capability are certainly an efficient way of taking decisions but their importance must not be exaggera-

ted. Without process analysis, i.e. without knowing the dispersion, random factors and system influences, the indices

are only of limited value and may lead to erroneous decisions being taken.

-3

σ

= 9.994

+3

σ

= 10.006

-NG

= 1

+NG

= 0

%DEF

= 0.893

Cp

= 1.3311

Cpk

= 1.3102

Cm

= 1.3252

Cmk

= 1.3068

23

(- NG) + (+ NG)

N

x 100