Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 30

Analog Inputs

30

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

3.

Multiply by the Volts/Hertz ratio

Therefore the command frequency from 0 to 2.5 volts on the analog input will be

15 Hz. After 2.5 volts, the frequency will increase at a rate of 0.16667 volts per

hertz to 7.5 volts. After 7.5 volts on the analog input the frequency command will

remain at 45 Hertz.

Example 2:

Consider the following setup:

•

[Anlg In Config], bit 0 = “0” (voltage)

•

[Speed Ref A Sel] = “Analog In 1”

•

[Analog In1 Hi] = 10V

•

[Analog In1 Lo] = 0V

•

[Speed Ref A Hi] = 50hz

•

[Speed Ref A Lo] = 0hz

•

[Maximum Speed] = 45hz

•

[Minimum Speed] = 15hz

The only change from Example 1 is the [Speed Ref A Hi] is changed to 50 Hz.

The deadband, as it relates to the analog input, can be calculated as follows:

1.

The ratio of analog input volts to frequency (Volts/Hertz) needs to be

calculated. The voltage span on the analog input is 10 volts. The frequency

span is 60 Hz.

2.

Determine the frequency span between the minimum and maximum speed

limits and the Speed Ref A Hi and Lo.

3.

Multiply by the volts/hertz ratio

15 Hz x 0.16667 Volts/Hz = 2.5 Volts

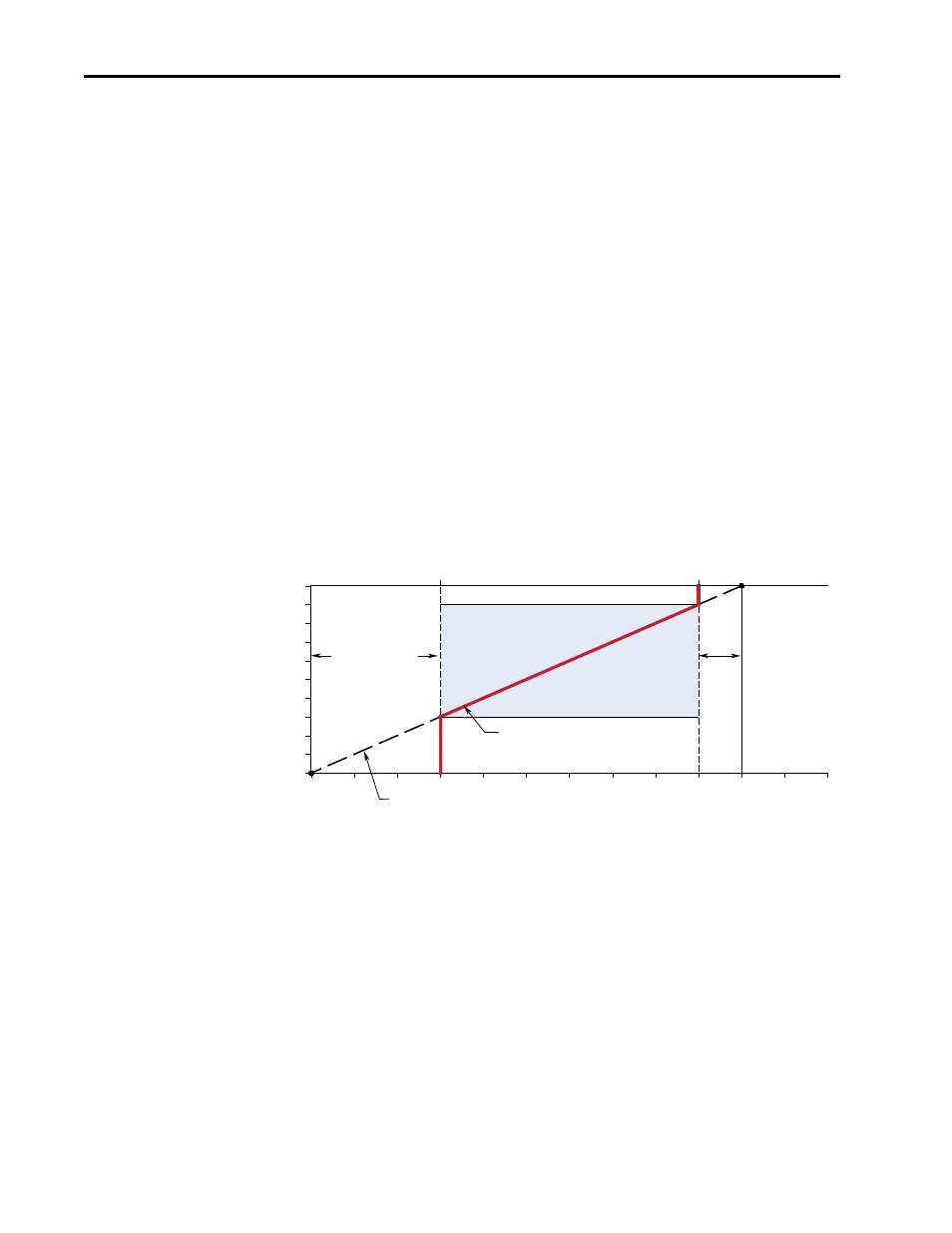

Motor Operating Range

[Maximum Speed]

[Minimum Speed]

Command Frequency

Slope defined by (Analog Volts)/(Command Frequency)

Frequency Deadband

Frequency Deadband

15 Hz

45 Hz

50 Hz

0 Hz

[Speed Ref A Lo]

[Speed Ref A Hi]

10V

0V

[Analog In1 Hi]

[Analog In1 Lo]

0-3 Volts

9-10 Volts

10 Volts/50 Hz = 0.2 Volts/Hz

[Speed Ref A Hi] – [Maximum Speed] = 50 – 45 = 5 Hz and . . .

[Minimum Speed] – [Speed Ref A Lo] = 15 – 0 = 15 Hz

5 Hz x 0.2 Volts/Hz = 1 Volt

15 Hz x 0.2 Volts/Hz = 3 Volts