Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 198

Stop Modes

198

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

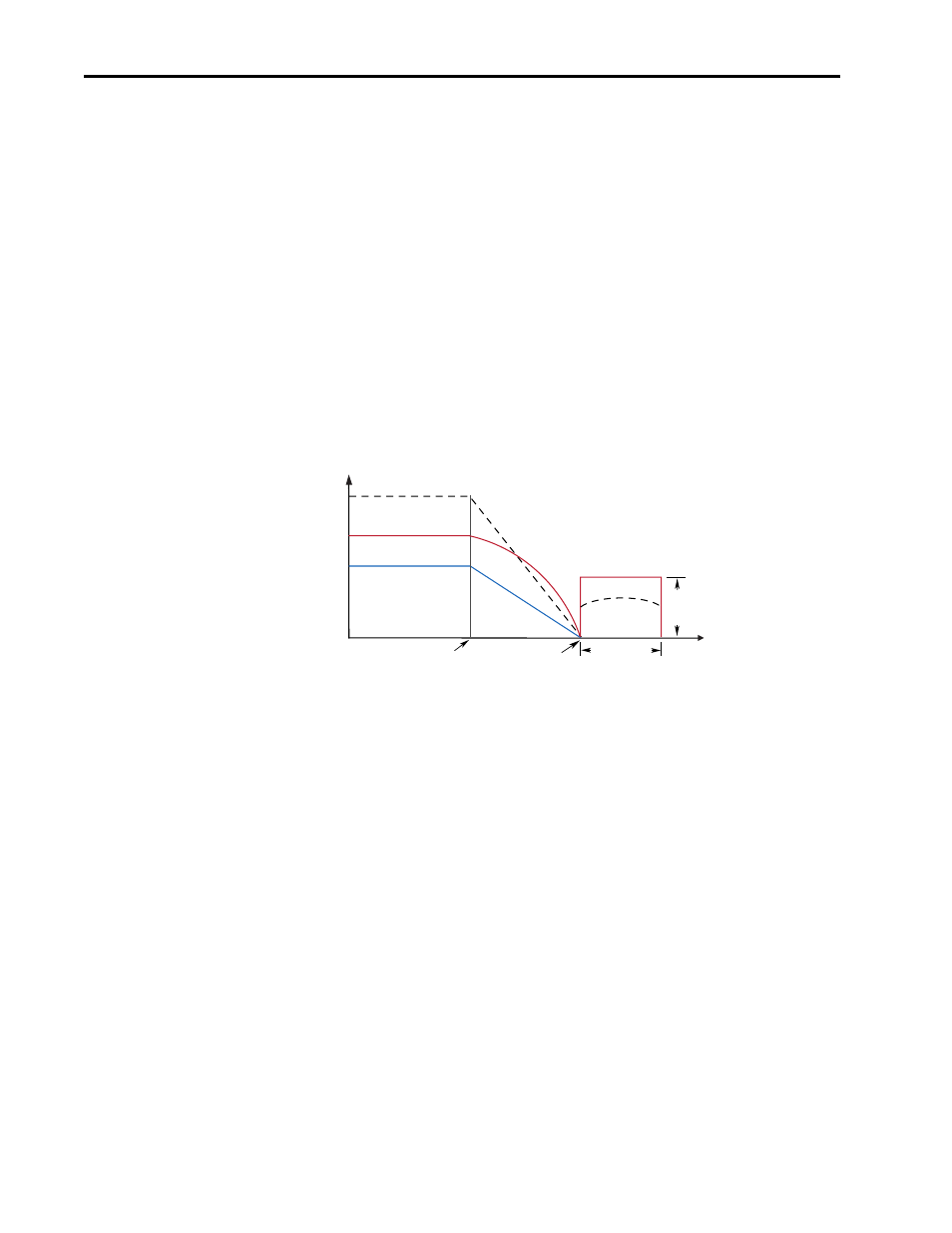

4. Ramp To Stop

is selected by setting [Stop Mode x]. The drive will ramp the

frequency to zero based on the deceleration time programmed into [Decel

Time 1/2]. The “normal” mode of machine operation can utilize [Decel Time

1]. If the “Machine Stop” mode requires a faster deceleration than desired for

normal mode, the “Machine Stop” can activate [Decel Time 2] with a faster

rate selected. When in Ramp to Stop, the drive acknowledges the Stop

command by decreasing or “ramping” the output voltage and frequency to

zero in a programmed period (Decel Time), maintaining control of the motor

until the drive output reaches zero. The output transistors are then shut off.

The load/motor should follow the decel ramp. Other factors such as bus

regulation and current limit can alter the decel time and modify the ramp

function.

Ramp mode can also include a “timed” hold brake. Once the drive has reached

zero output hertz on a Ramp-to-Stop and both parameters [DC Hold Time]

and [DC Hold Level] are not zero, the drive applies DC to the motor

producing current at the DC Hold Level for the DC Hold Time.

Motor speed during and after the application of DC depends upon the

combination of the these two parameter settings, and the mechanical system.

The drive output voltage will be zero when the hold time is finished.

The level and uniformity of the DC braking offered at zero speed may not be

suitably smooth for many applications. If this is an application requirement, a

vector control drive, motion control drive or mechanical brake should be

used.

The drive output voltage will be zero when the hold time is finished

DC Hold Time

DC

Hold

Level

Stop

Command

Time

Output Voltage

Output Current

Motor Speed

Output Voltage

Output Current

Zero

Command

Speed