Torque reference, Torque reference input – Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 204

Torque Reference

204

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

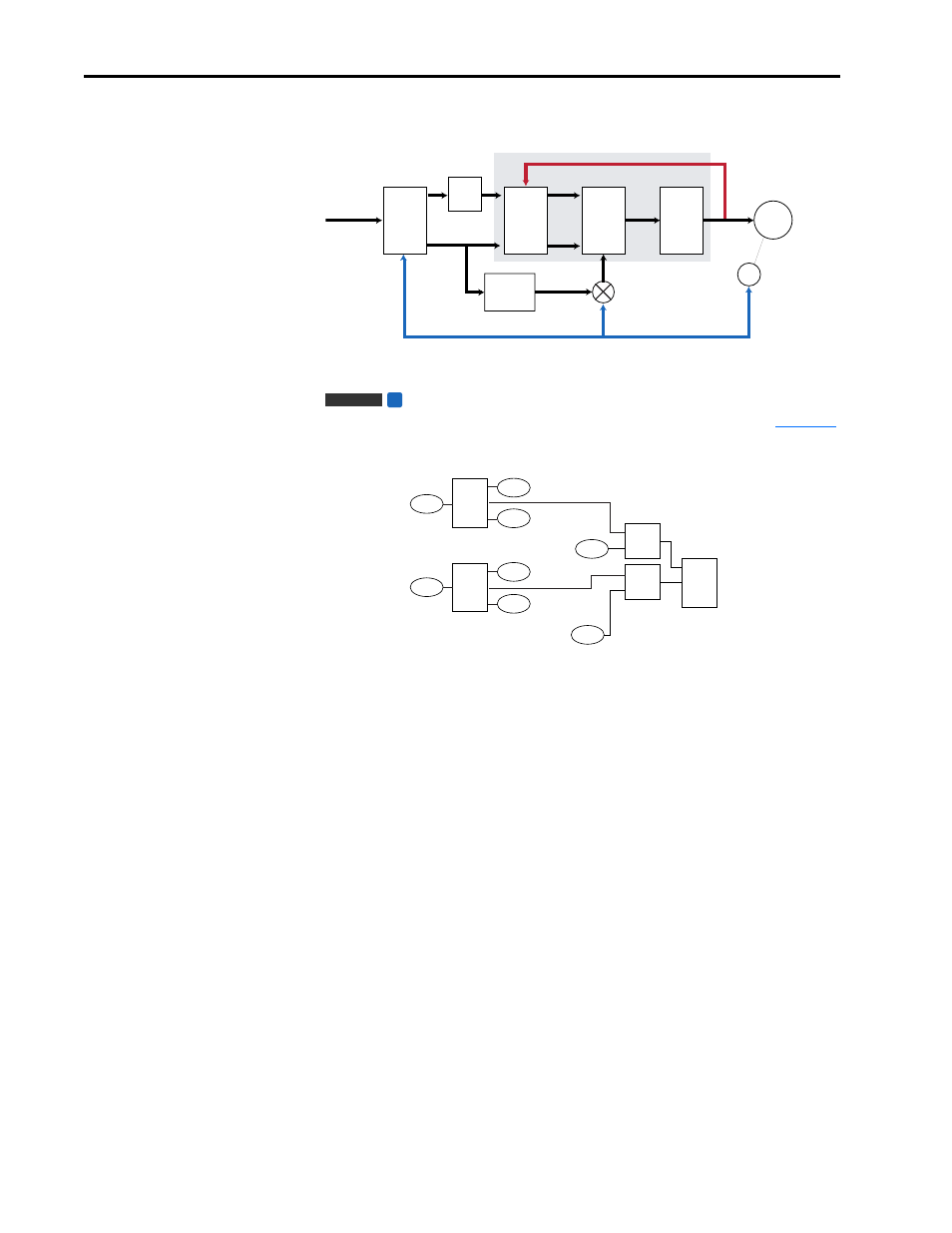

Figure 59 Flux Vector

Torque Reference

When the PowerFlex 700 Vector Control drive is operated in

Torque mode, an external signal is used for a Torque reference. Refer to

.

Figure 60

Torque Reference Input

[Torque Ref A], parameter 427 is used to supply an external reference for how

much torque is desired. The scaling of this parameter is from –800 to +800, via

[Torq Ref A Hi] and [Torq Ref A Lo].

Torque Ref 1 is then divided by [Torq Ref A Div], parameter 430. This defines

the scaled Torque Ref A.

[Torque Ref B], parameter 431 is used to supply an external reference for how

much torque is desired. The scaling of this parameter is from –800 to +800, via

[Torq Ref B Hi] and [Torq Ref B Lo].

The Torque Ref B is then multiplied by [Torq Ref B Mul], parameter 434. This

defines the scaled Torque Ref B.

Once the scaling is complete on both Torque Ref A and Torque Ref B, the output

is summed to create the external torque reference

This can be utilized when a master/slave multi-drive system is configured. The

torque reference into the “slave” can be scaled to create the proper torque output.

Keep in mind that the motors may be different ratings and this function is used

to help the “system” share the load.

Adaptive

Controller

High Bandwidth Current Regulator

SPEED REF.

TORQUE REF.

SLIP

SPEED FEEDBACK

CURRENT FEEDBACK

AUTOTUNE PARAMETERS

V mag

V ang

Current

Reg.

Speed

Reg.

Flux

Reg.

Voltage

Control

Inverter

Motor

Encoder

Vector

FV

431

Scale

Scale

433

432

429

428

434

430

/

x

+

Ref A Hi

Ref A Lo

Ref B Hi

Torq Ref A Div

Torq Ref B Mult

Ref B Lo

Torque Ref B Sel

427

Torque Ref A Sel