Pi setpoint, Pi output, Pi gains – Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 144

Process PI Loop

144

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

Configuration Example:

The PI reference meter and PI feedback meter should be displayed as positive and

negative values. Feedback from our dancer comes into Analog Input 2 as a 0-10V

DC signal.

•

[PI Reference Sel] = 0 “PI Setpoint”

•

[PI Setpoint] = 0 %

•

[PI Feedback Sel] = 2 “Analog In 2”

•

[PI Reference Hi] = 100 %

•

[PI Reference Lo] = –100 %

•

[PI Feedback Hi] = 100 %

•

[PI Feedback Lo] = –100 %

•

[Analog In 2 Hi] = 10V

•

[Analog In 2 Lo] = 0V

Now 5V corresponds to 0% on the PI Feedback, so we will try to maintain a PI

setpoint of 0% (5V). Now [PI Ref Meter] and [PI Fdback Meter] are displayed as

bipolar values.

PI Setpoint

This parameter can be used as an internal value for the setpoint or reference for

the process. If [PI Reference Sel] points to this Parameter, the value entered here

will become the equilibrium point for the process.

PI Output

The PI Error is then sent to the Proportional and Integral functions, which are

summed together.

PI Gains

The PI Proportional Gain and the PI Integral Gain parameters determine the

response of the PI.

The PI Proportional Gain is unitless and defaults to 1.00 for unit gain. With PI

Proportional Gain set to 1.00 and PI Error at 1.00% the PI output will be 1.00%

of maximum frequency.

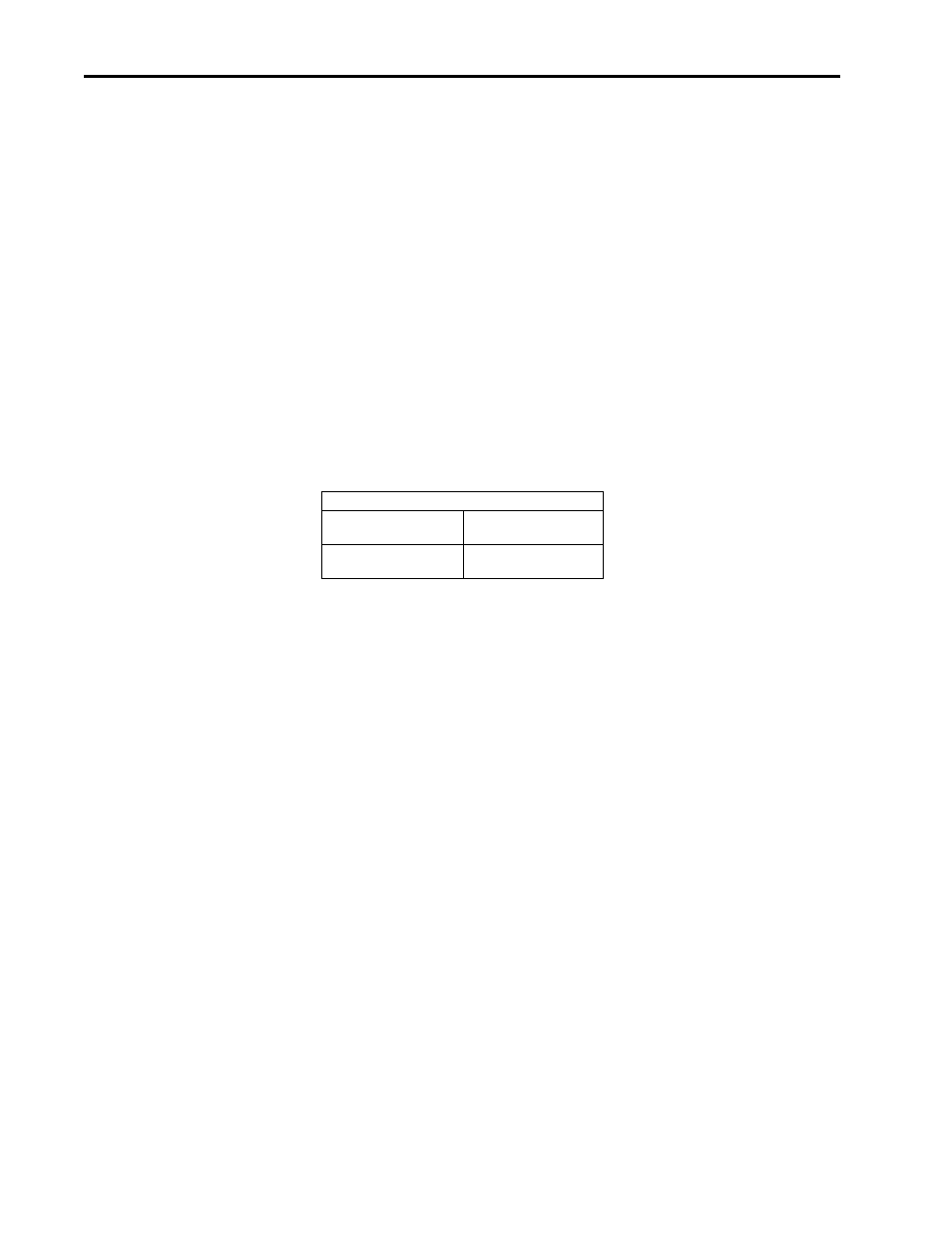

PI Feedback Scaling

[Torque Ref A Sel] = “Analog In 1”

[Analog In 2 Hi]

10 V

[PI Feedback Hi]

100 %

[Analog In 1 Lo]

0V

[PI Feedback Lo]

-100 %