Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 164

Speed Control, Mode, Regulation & Vector Speed Feedback

164

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

original speed. Conversely, when the load is removed, the rotor speed increases

momentarily until the slip compensation decays to zero.

Motor nameplate data must be entered by the user in order for the drive to

correctly calculate the proper amount of slip compensation. The motor

nameplate reflects slip in the rated speed value at rated load. The user can enter

the Motor Nameplate RPM, Motor Nameplate Frequency, the Motor Nameplate

Current, Motor Nameplate Voltage, and Motor Nameplate HP/kW and during

commissioning the drive calculates the motor rated slip frequency and displays it

in [Slip RPM @ FLA]. The user can adjust the slip compensation for more

accurate speed regulation, by increasing or decreasing [Slip RPM @ FLA] value.

Internally, the drive converts the rated slip in RPM to rated slip in frequency. To

more accurately determine the rated slip frequency in hertz, an estimate of flux

current is necessary. This parameter is either a default value based on motor

nameplate data or the auto tune value. The drive scales the amount of slip

compensation to the motor rated current. The amount of slip frequency added to

the frequency command is then scaled by the sensed torque current (indirect

measurement of the load) and displayed.

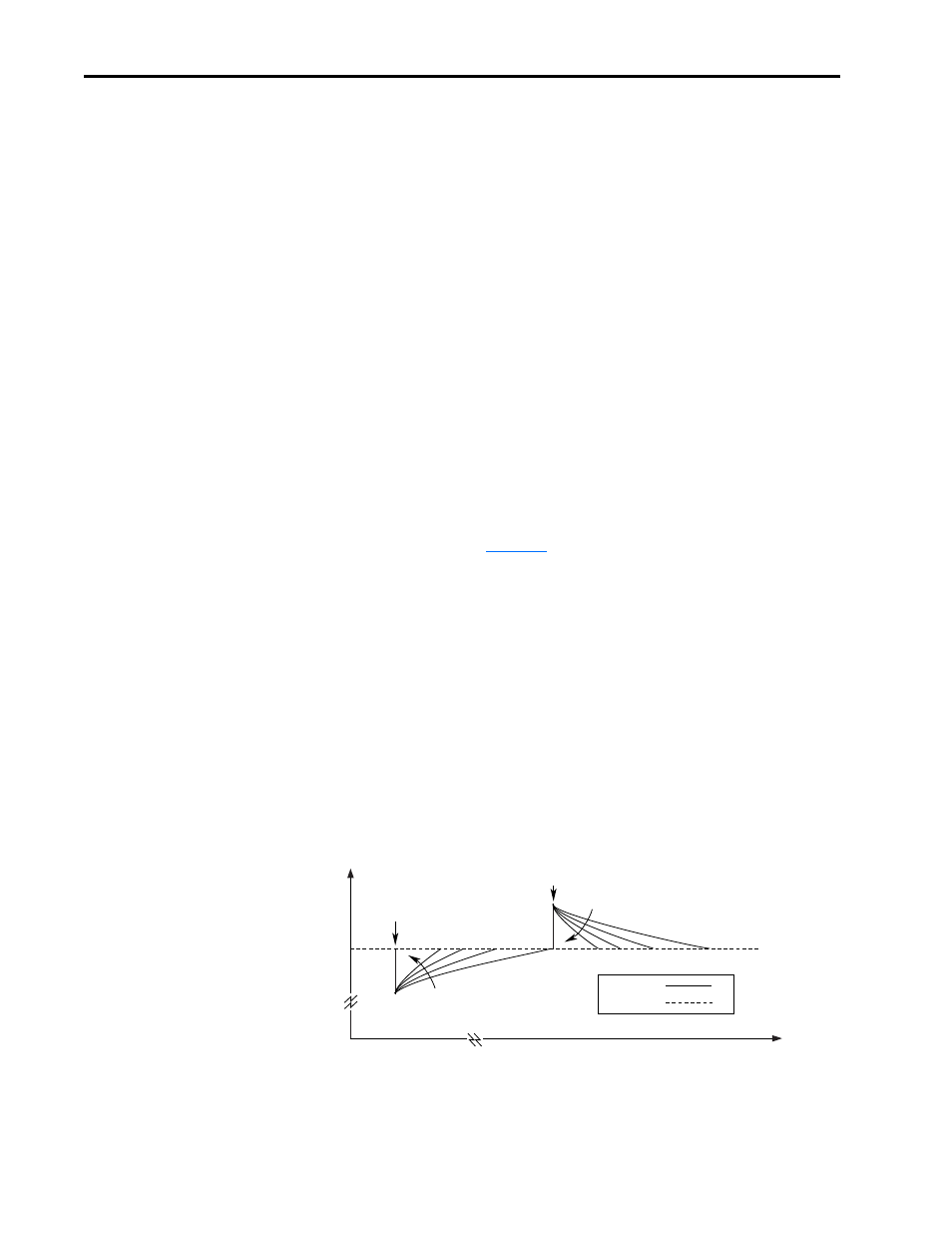

Slip compensation also affects the dynamic speed accuracy (ability to maintain

speed during “shock” loading). The effect of slip compensation during transient

operation is illustrated in

. Initially, the motor is operating at some

speed and no load. At some time later, an impact load is applied to the motor and

the rotor speed decreases as a function of load and inertia. And finally, the impact

load is removed and the rotor speed increases momentarily until the slip

compensation is reduced based on the applied load.

When slip compensation is enabled the dynamic speed accuracy is dependent on

the filtering applied to the torque current. The filtering delays the speed response

of the motor/drive to the impact load and reduces the dynamic speed accuracy.

Reducing the amount of filtering applied to the torque current can increase the

dynamic speed accuracy of the system. However, minimizing the amount of

filtering can result in an unstable motor/drive. The user can adjust the Slip Comp

Gain parameter to decrease or increase the filtering applied to the torque current

and improve the system performance.

Figure 34 Rotor Speed Response Due to Impact Load and Slip Com Gain

Time

Speed

0

0

Impact Load

Applied

Impact Load

Removed

Increasing Slip

Comp Gain

Increasing Slip

Comp Gain

Rotor Speed

Reference