Additional resources general precautions, General precautions – Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 10

Preface

10

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

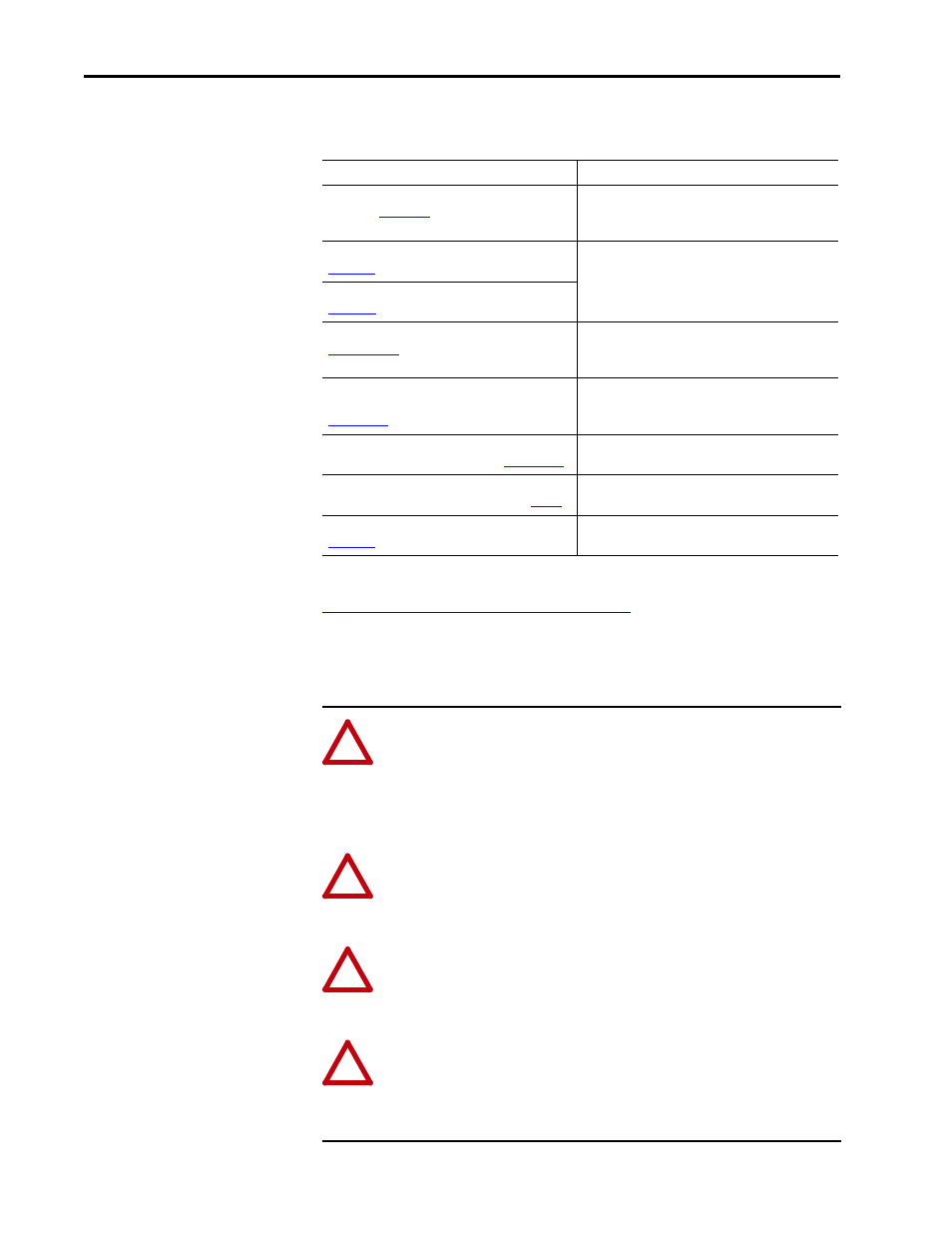

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

You can view or download publications at

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

General Precautions

Resource

Description

PowerFlex 700 Standard Control User Manual,

publication

Provides detailed information on:

• Parameters and programming

• Faults, alarms, and troubleshooting

PowerFlex 70 AC Drive Technical Data, publication

This publication provides detailed drive specifications,

option specifications and input protection device ratings.

PowerFlex 700 AC Drive Technical Data, publication

PowerFlex Comm Adapter Manuals, publication

20COMM-UM…

These publications provide information on configuring,

using, and troubleshooting PowerFlex communication

adapters.

PowerFlex 70 Enhanced Control and PowerFlex 700

Vector Control Reference Manual, publication

These publications provide detailed application specific

information for programming and configuring the

PowerFlex 700 drive.

Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives, publication

Provides basic information needed to properly wire and

ground PWM AC drives.

Safety Guidelines for the Application, Installation and

Maintenance of Solid State Control, publication

Provides general guidelines for the application,

installation, and maintenance of solid-state control.

Guarding Against Electrostatic Damage, publication

Provides practices for guarding against Electrostatic

damage (ESD)

!

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference A-B publication 8000-4.5.2, “Guarding Against

Electrostatic Damage” or any other applicable ESD protection handbook.

!

ATTENTION: An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors, such as,

undersizing the motor, incorrect or inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the system.

!

ATTENTION: Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation,

start-up and subsequent maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

!

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged before performing any work on the drive.

Measure the DC bus voltage at the +DC & –DC terminals of the Power Terminal

Block (refer to the Installation Instructions for location). The voltage must be

zero.