Process trim – Rockwell Automation 20B PowerFlex 70, PowerFlex 700 Reference Manual User Manual

Page 136

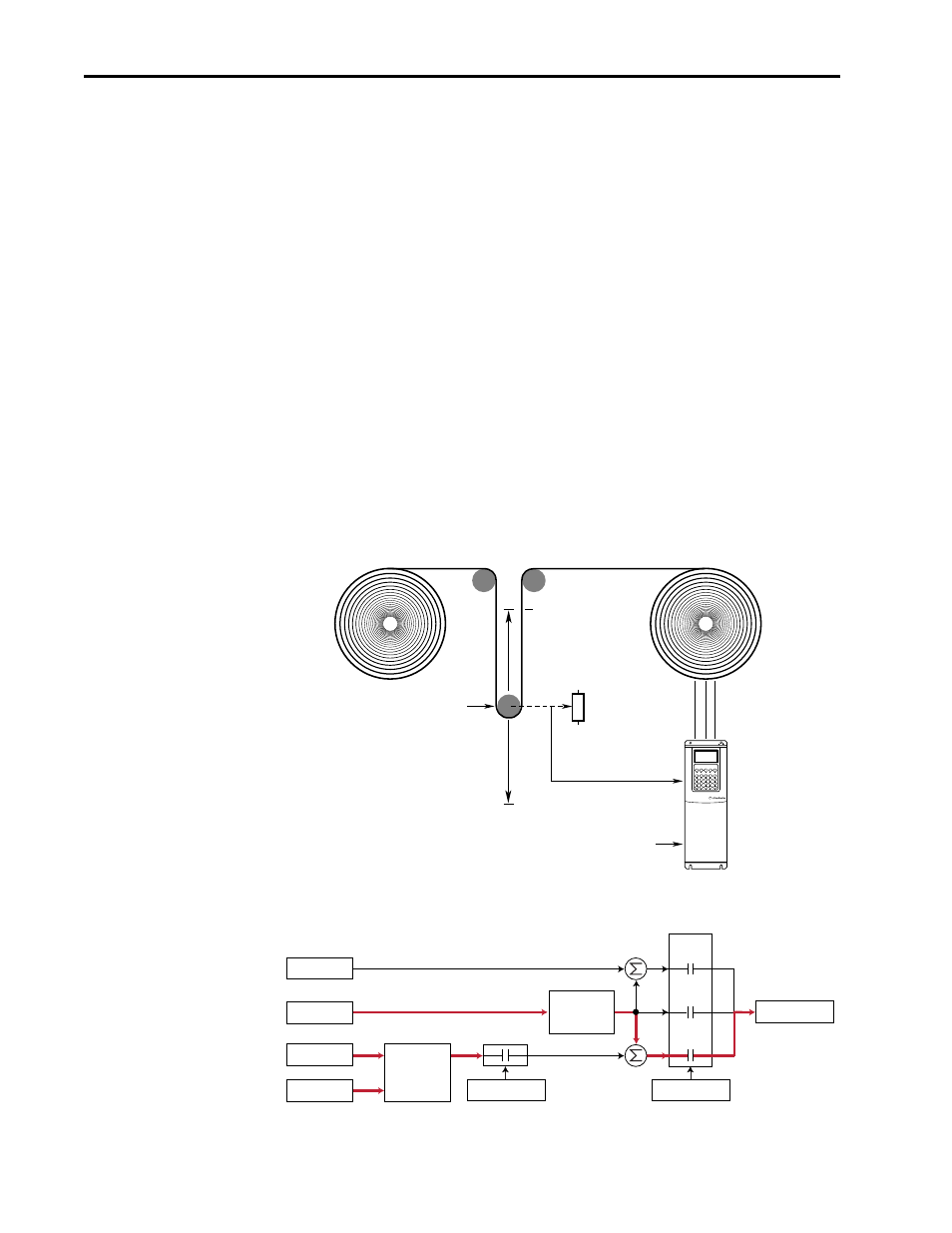

Process PI Loop

136

Rockwell Automation Publication PFLEX-RM001H-EN-P - June 2013

The PI function can perform a combination of proportional and integral control.

It does not perform derivative control, however, the accel / decel control of the

drive can be considered as providing derivative control.

There are two ways the PI Controller can be configured to modify the

commanded speed.

•

Process Trim - The PI Output can be added to the master speed reference

•

Process Control - PI can have exclusive control of the commanded speed.

The selection between these two modes of operation is done in the [PI

Configuration] parameter.

Process Trim

Process Trim takes the output of PI regulator and sums it with a master speed

reference to control the process. In the following example, the master speed

reference sets the wind/unwind speed and the dancer pot signal is used as a PI

Feedback to control the tension in the system. An equilibrium point is

programmed as PI Reference, and as the tension increases or decreases during

winding, the master speed is trimmed to compensate and maintain tension near

the equilibrium point.

When the PI is disabled the commanded speed is the ramped speed reference.

Master Speed Reference

10 Volts

0 Volts

Dancer Pot

[PI Feedback Sel]

Equilibrium Point

[PI Reference Sel]

+

Spd Cmd

Process PI

Controller

Linear Ramp

& S-Curve

+

+

+

PI Disabled

Speed Control

Spd Ref

PI Ref

PI Fbk

Slip Adder

Open

Loop

Slip

Comp

Process

PI