Tachometer signal processing parameters – Rockwell Automation 1440-VSE02-01RA XM-122 gSE Vibration Module User Manual

Page 82

Publication GMSI10-UM013D-EN-P - May 2010

72 Configuration Parameters

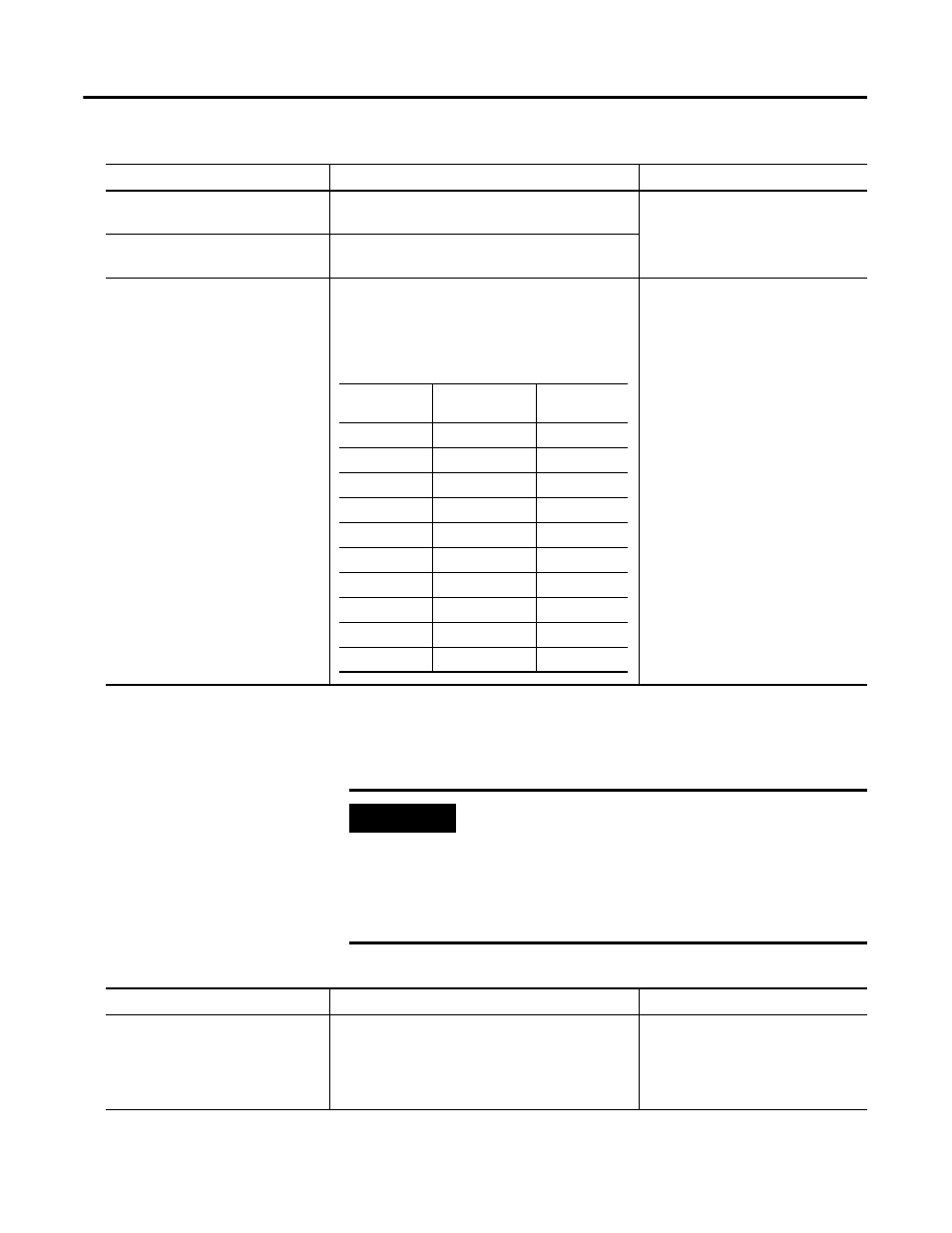

Tachometer Signal Processing Parameters

Fault Low

The minimum, or most negative, expected DC

voltage from the transducer.

Volts

Note: A voltage reading outside this

range constitutes a transducer fault.

Fault High

The maximum expected DC voltage from the

transducer.

DC Bias Time Constant

The time constant used for exponential averaging

(low pass filtering) of the transducer DC bias

measurement. The corner frequency for the low pass

filter is 1 / (2

π

x DC Bias Time Constant). See

example table below.

Seconds

Tachometer Transducer Parameters

Parameter Name

Description

Values/Comments

Time Constant

(seconds)

-3dB Frequency

(Hz)

Settling Time

(seconds)

1

0.159

2.2

2

0.080

4.4

3

0.053

6.6

4

0.040

8.8

5

0.032

11

6

0.027

13.2

7

0.023

15.4

8

0.020

17.6

9

0.018

19.8

10

0.016

22

IMPORTANT

The tachometer is required for synchronous sampling and

the speed measurement.

If you are not using the tachometer channel, set the Pulses

Per Revolution to zero. This will disable the tachometer

measurement, and prevent the module from indicating a

tachometer fault.

Tachometer Signal Processing Parameters

Parameter Name

Description

Values/Comments

Pulses Per Revolution

The number of tachometer signal pulses per

revolution of the shaft (number of gear teeth). This

setting is useful if a proximity probe located over a

gear or shaft with a multi-toothed speed sensing

surface is used to generate the input signal.

Enter zero if you are not using the

tachometer channel to disable the

tachometer measurement.