Rockwell Automation 1440-VSE02-01RA XM-122 gSE Vibration Module User Manual

Page 164

Publication GMSI10-UM013D-EN-P - May 2010

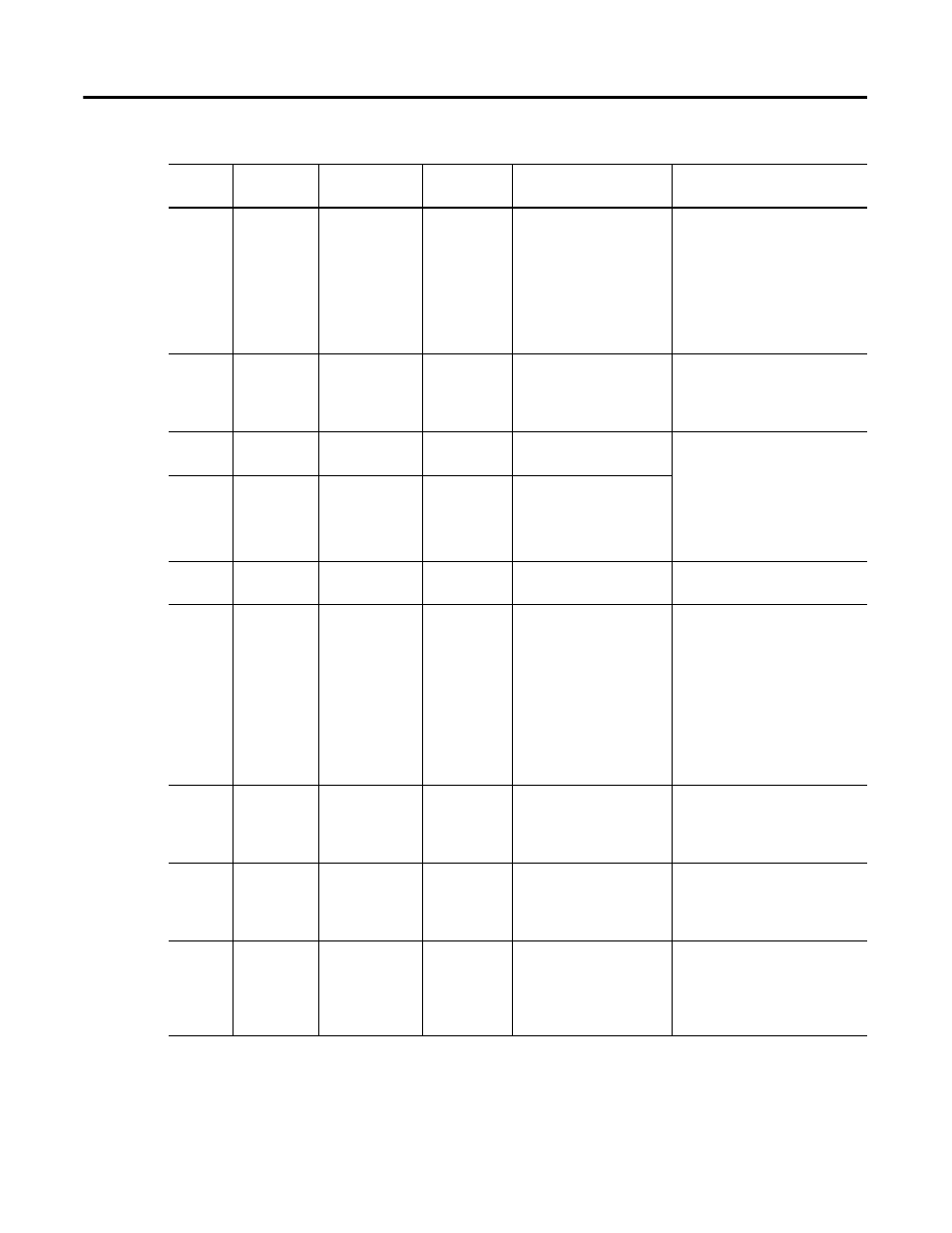

154 DeviceNet Objects

5

Get/Set

Low Cutoff

Frequency

USINT

The effective high pass

filter (low frequency

corner) selection.

0 = Very low

1 = Low

2 = Medium

3 = High

4 = Very high

5 = Bypass

See attributes 100 to 104.

6

Get/Set

Synchronous

BOOL

Indicates whether this

channel is synchronized

with the tachometer

signal.

0 = Asynchronous

1 = Synchronous

For instances 3 and 4, this value

is fixed at 0 = Asynchronous.

7

Get/Set

Internal Gear

Teeth

UINT

The number of gear teeth

on the shaft of interest.

The Internal/External Gear

Teeth values are used when

synchronous operation is

selected but there is a known

speed difference between the

shaft of interest and the shaft

used as the tachometer source.

8

Get/Set

External Gear

Teeth

UINT

The number of gear teeth

on the shaft used as the

tachometer source.

9

Get/Set

Name

STRING2

A name to help identify

this channel.

10

Get/Set

Full Scale

REAL

The maximum signal

expected to be processed

by the channel.

Volts peak

Setting the Full Scale to a

greater value allows the

channel to handle greater input

signals without saturating or

clipping. Setting the Full Scale

to a lesser value allows the

signal to be measured with

greater resolution.

100

Get

Very Low HPF

Corner

Frequency

REAL

The frequency, in Hz, of

the "Very low" Low

Cutoff Frequency option

for attribute 5.

Hz

101

Get

Low HPF Corner

Frequency

REAL

The frequency, in Hz, of

the "Low" Low Cutoff

Frequency option for

attribute 5.

Hz

102

Get

Medium HPF

Corner

Frequency

REAL

The frequency, in Hz, of

the "Medium" Low

Cutoff Frequency (low

frequency corner) option

for attribute 5.

Hz

Table C.41 Channel Object Instance Attributes

Attr ID

Access

Rule

Name Data

Type

Description

Semantics