Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - Classic Control User Manual

Page 466

7-44

Troubleshooting

7000-UM150I-EN-P – June 2013

7000 “B” Frame

WARNING

MESSAGE

WARNING

CODE

DESCRIPTION

RECOMMENDED ACTIONS

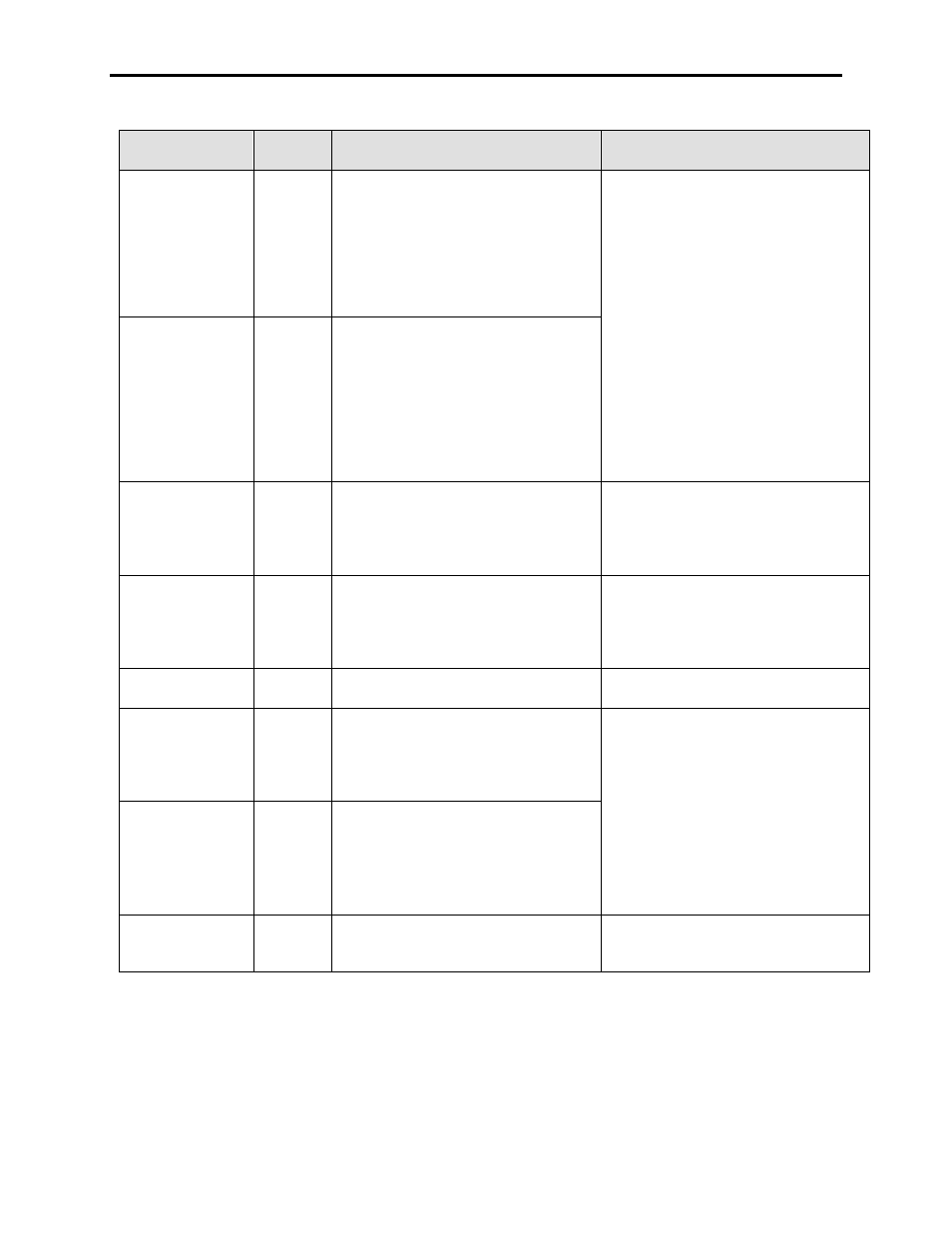

Rec HS Sensor

201

While Running, the drive has detected a

missing temperature sensor connected to

the TFB on the rectifier heatsink. A missing

sensor can result in either a Fiber Optic

Loss fault or a Sensor fault because a

missing sensor can be interpreted as either

0°C or over 100°C, and both are unrealistic

values.

– Verify sensor is completely seated

properly on TFB.

– Measure sensor resistance.

– Replace if necessary.

– NOTE: This is a warning because the

drive should not fault on the loss of the

signal while running. There is no

imminent danger to the drive, but the

user needs to be aware that there is a

temperature feedback signal missing.

Rec ChB Sensor

202

Not normally used: While Running, the

drive has detected a missing temperature

sensor connected to the optional TFB

connected to the fiber optic receiver RX7 on

FOI-L-B. A missing sensor can result in

either a Fiber Optic Loss fault or a Sensor

fault because a missing sensor can be

interpreted as either 0°C or over 100°C, and

both are unrealistic values.

Reg in Limit

51

Either the Speed Regulator or the Flux

Regulator autotune test hit the regulator limit

and the results of the test are not valid.

– REFER TO THE POWERFLEX 7000

SERIES B MANUAL (CHAPTER 4 –

COMMISSIONING) ON AUTOTUNE

PROCEDURES, RESULTS, AND

ACTIONS

Slip Range

189

This warning appears when unusual values

for slip appear, indicating there is either an

error in data or an unusual motor. The rated

slip for this warning has to be > 10%, or <

0.01%

– Verify Motor Nameplate Data

– Contact the factory with the motor data

and the application information

Slave 0-7 OffL

348-355

Slave (0-7) DAN Communication Loss-

Master only

– Slave is Off line.

Slave1 UV

113

The measured value V Slave1 Average

(P137) is less than Line Undervoltage Trip

(P167) as a percentage of 1/3 Rated Line

Voltage (P18), for the period set by Line

Undervoltage Delay (P168).

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm integrity

– Check TSN fusing

– Check actual voltage values on the

Terminal for each bridge and the total

line voltage

– Check for possible source voltage

supply problems

– Use Multimeter and Oscilloscope to

check voltages on the drive test points

Slave2 UV

114

The measured value V Slave2 Average

(P138) is less than Line Undervoltage Trip

(P167) as a percentage of 1/3 Rated Line

Voltage (P18), for the period set by Line

Undervoltage Delay (P168).

Slv RfsdMstr

343

Slave refused Master-master only

– Slave has lost communication with hub

PLC, or slave is masked off in parameter

Master Mask