Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - Classic Control User Manual

Page 428

7-6

Troubleshooting

7000-UM150I-EN-P – June 2013

7000 “B” Frame

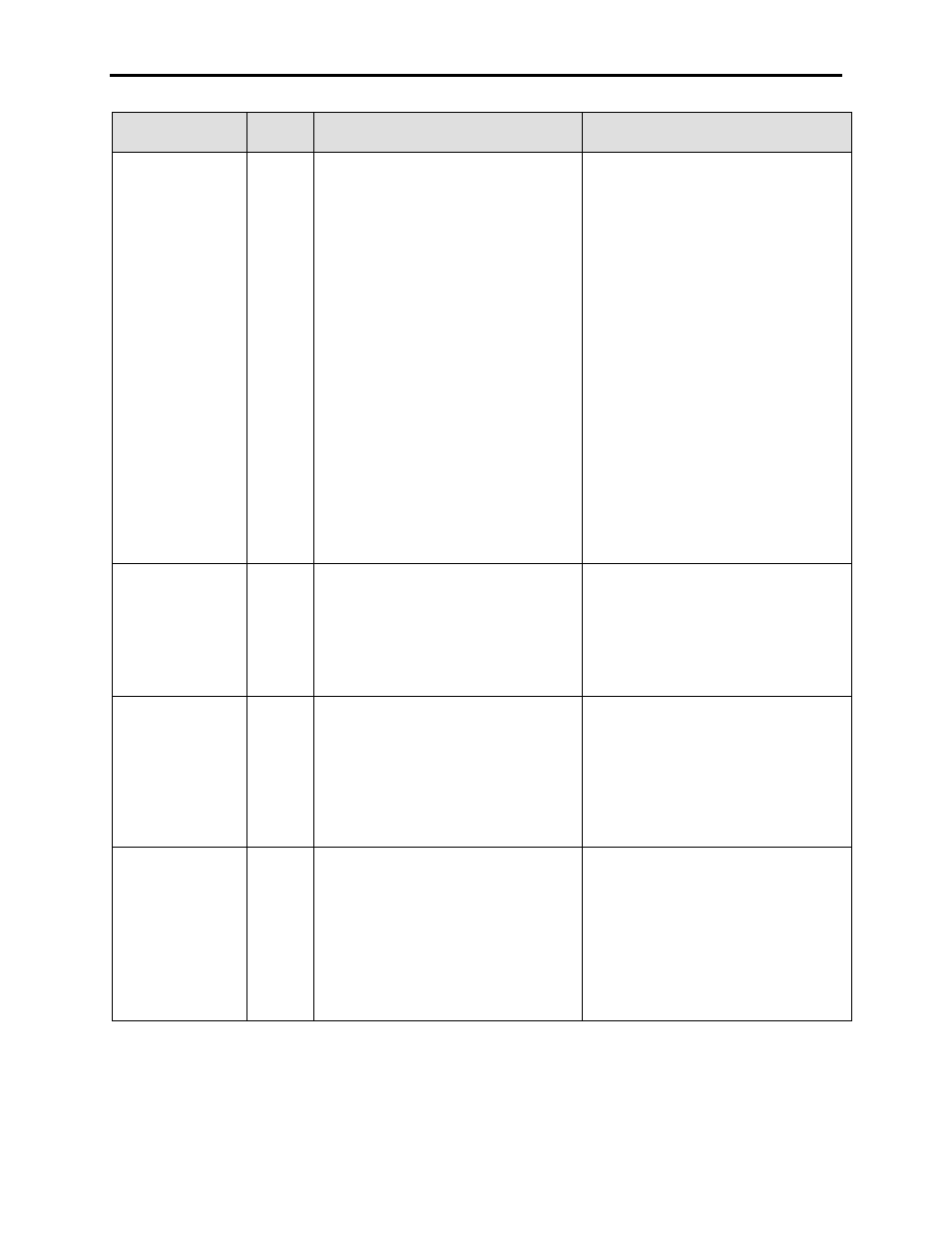

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION

RECOMMENDED ACTIONS

– If you have the Cap/CT Error code, this

only occurs for PWM rectifiers when

energized and not running. The line

current measured by the CTs does not

match the expected line current based

on the capacitor parameters and

measured voltage. Possible causes are

incorrect capacitor, CT or burden resistor

parameters, and in some cases, blown

TSN fuses.

– If you have the Motor HECS code, this

only occurs when running on the motor in

open loop mode. The drive compares the

motor current to the dc current, and flags

this fault if there is a significant difference.

If there were no Line HECS/CT codes,

then the likely cause of this fault in an

incorrectly programmed motor HECS

value or burden resistor. Other causes

could be a defective or unplugged motor

HECS.

DAN Comm

45

Drive Area network communication fault.

This is applicable to parallel drive only

– Check RS485/RS232 converter. Red

LED should be steady, and green and

yellow transmit and receive LEDs should

be flashing.

– Check RS485 cable between drives

– Check RS232 cable between Inverter

Drive Control Board and serial converter

DC Link Flow Low

(C-Frame Only)

231

The flow switch in the DC Link coolant path

has detected the flow is less than optimal,

indicating a problem with the flow path. This

is not designed to specifically measure flow.

This is a switch that differentiates between

flow and no flow.

– Verify pressure values in the cooling

system are nominal

– Verify the cooling path is not restricted

because of tube crimping

– Check flow switch for proper operation

– It may be required to disconnect cooling

path and complete a check on the DC

Link for blockages

DC Link OC HW

170

The measured I DC Link Feedback (P322)

has exceeded DC Overcurrent Trip (P169)

or 75% of the device rating, whichever is

lower. The drive faults instantaneously.

– Verify that the parameters for drive and

device ratings, and installed current

sensing components are set accordingly

– Verify that the DC Link LEM is wired

properly and properly powered

– Verify the Burden Resistor value

– Complete a DC Current Test to verify the

feedback corresponds to the IDC

Command