Hall effect currentsensor replacement, Hall effect current sensor replacement – Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - Classic Control User Manual

Page 303

Component Definition and Maintenance 6-13

7000 “B” Frame

7000-UM150I-EN-P – June 2013

1. Ensure there is no power to the equipment.

A T T E N T I O N

A T T E N T I O N

To prevent electrical shock, ensure the main

power has been disconnected before working on

the Hall Effect current sensor. Verify that all

circuits are voltage free using a hot stick or

appropriate voltage-measuring device. Failure to

do so may result in injury or death.

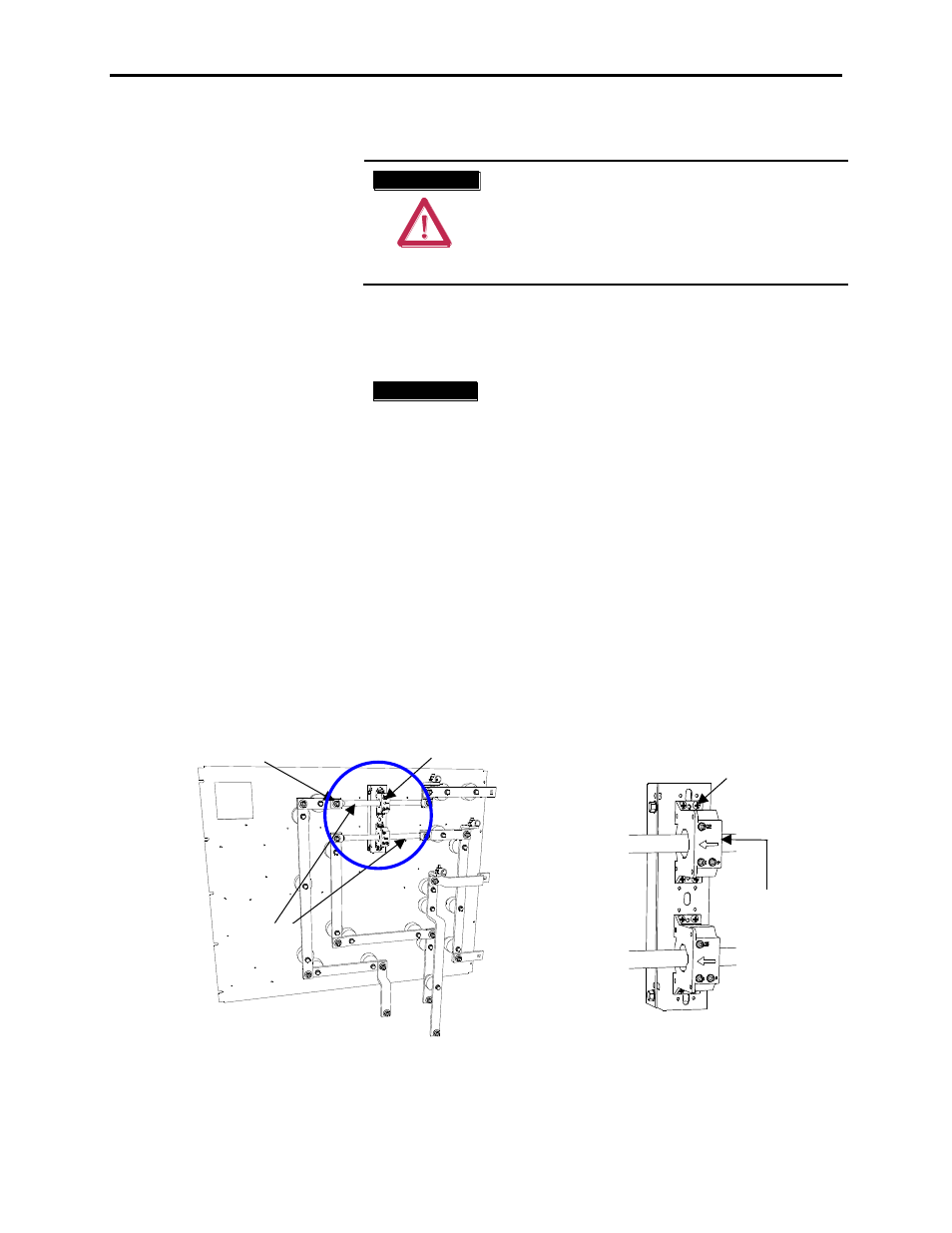

2. Note the location of all wires and the orientation of the Hall Effect

current sensor. For quick reference when checking the orientation

of the Hall Effect current sensor, look for the white arrow.

I M P O R T A N T

I M P O R T A N T

The Hall Effect current sensor and wires must be

in the proper orientation. Note the position before

disassembly.

3. The round bus bar must be removed. Remove the M10 hardware

and slide the bar out.

4. Remove the screws from the three terminals to allow removal of

the ring lugs.

5. Remove the four screws on the base of the Hall Effect current

sensor.

6. Replace the Hall Effect current sensor. Note the arrow must be

oriented as shown in the illustration below.

7. Slide the bus bar back into place and secure with the M10 hardware.

8. Fasten the ring lugs on the wires back into place in the correct

position. Do not overtighten or you will break the threaded stud.

Detail:

LEM

Base hardware

M10 hardware

Bus Bar

Arrow must be

oriented

properly.

Arrows must

be oriented

properly.

Hall Effect Sensor

Hall Effect Current Sensor

Figure 6.11 – Hall Effect Current Sensor located within cabinet with detail

Hall Effect Current

Sensor Replacement