Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - Classic Control User Manual

Page 462

7-40

Troubleshooting

7000-UM150I-EN-P – June 2013

7000 “B” Frame

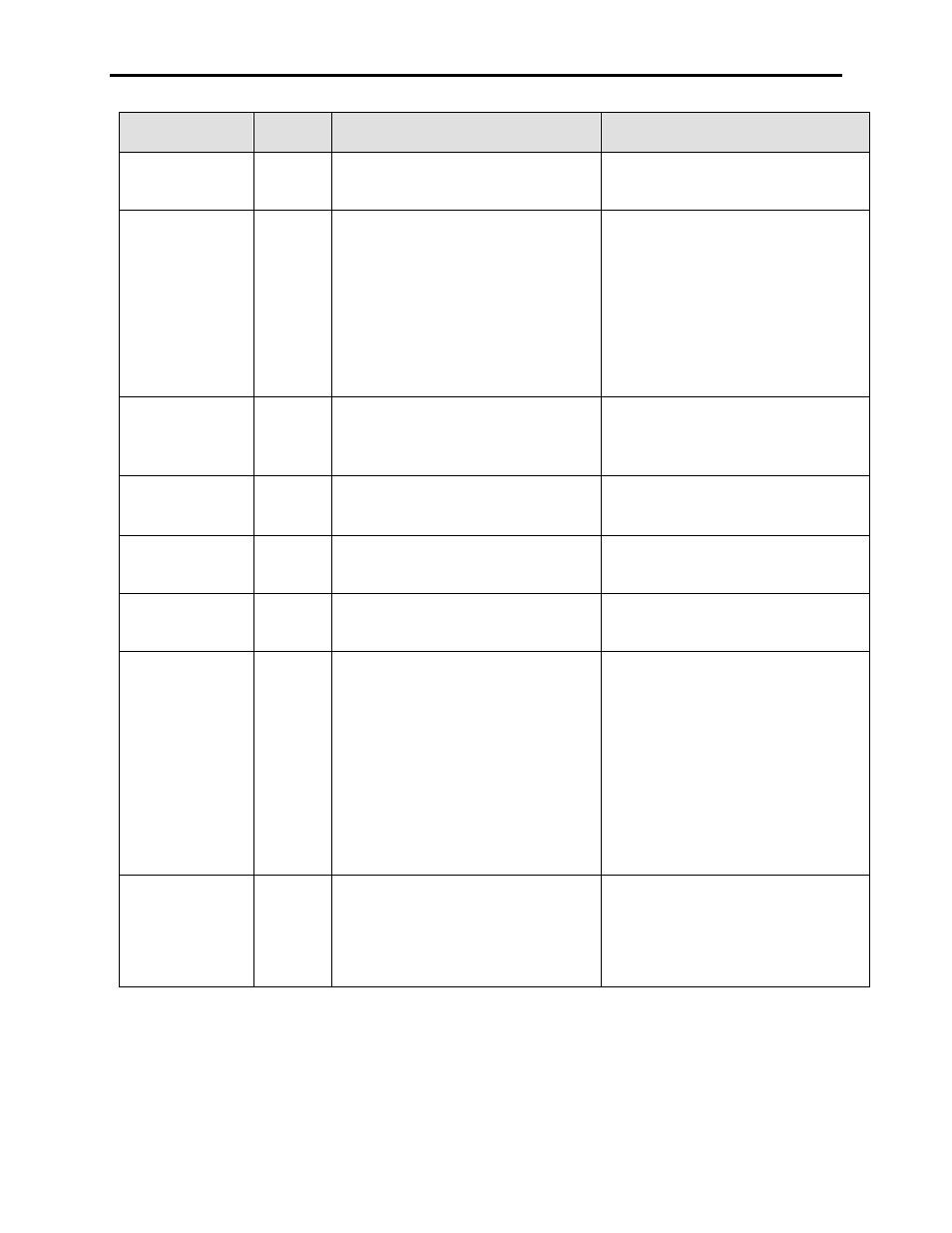

WARNING

MESSAGE

WARNING

CODE

DESCRIPTION

RECOMMENDED ACTIONS

Line DC Link OV

116

The measured Line DC voltage has

exceeded Line DC Overvoltage Trip (P173),

and instantaneously causes a warning.

– See associated Fault Description

Line Loss

120

The drive has detected a loss of input

voltage from losing the frequency (PLL) lock

on the input voltage. This is designed to be

a faster method of detecting an

undervoltage. The drive responds to this

warning as it does to a Master UV warning.

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm

integrity

– Check TSN fusing

– Check actual voltage values on the

Terminal for each bridge and the total

line voltage

– Check for possible source voltage

supply problems

Liq IO Config

(C-Frame Only)

131

The XIO card which was being assigned to

the Liquid Cooling System Faults Input is

not a card which can be used for this

purpose

– Select the proper slot containing the XIO

card which is compatible for Liquid

Cooling System Faults usage.

Liq IO Conflict

(C-Frame Only)

132

The XIO card previously being used for

Liquid Cooling System Faults has been

reassigned for another purpose.

– Check the configuration of all XIO slots

and reassign if necessary.

Logx IO Config

133

The XIO card which was being assigned to

Logix IO (basic PLC functionality) is not a

card which can be used for this purpose

– Select the proper slot containing the XIO

card which is compatible for Logix IO

usage.

Logx IO Conflict

134

The XIO card previously being used for

Logix IO (basic PLC functionality) has been

reassigned for another purpose.

– Check the configuration of all XIO slots

and reassign if necessary.

Master UV

112

The measured value V Master Average

(P136) is less than Line Undervoltage Trip

(P167) with respect to 1/3 Rated Line

Voltage (P18) [for 18-pulse drives], and

Rated Line Voltage (P18) [for 6-pulse and

PWM drives] for the period set by Line

Undervoltage Delay (P168).

– Verify the VSB connections and tap

settings, and check resistance of VSB

board – Megger board to confirm

integrity

– Check TSN fusing

– Check actual voltage values on the

Terminal for each bridge and the total

line voltage

– Check for possible source voltage

supply problems

– Use Multimeter and Oscilloscope to

check voltages on the drive test points

Motor Cap Range

23

The calculated per unit value of the Motor

Filter Capacitor (P128), based on the values

entered for Motor Capacitor kVAR (P20),

Motor Capacitor Volts (P21), and Motor

Capacitor Frequency (P28) is outside of the

normal range of 0.26-0.55 pu.

– Verify capacitor nameplate data and

compare with information entered in

drive

– Contact factory