Impeller maintenance – Rockwell Automation 7000 PowerFlex Medium Voltage AC Drive (B Frame) - Classic Control User Manual

Page 348

6-58

Component Definition and Maintenance

7000-UM150I-EN-P – June 2013

7000 “B” Frame

Fan Installation

Care must be taken in handling of the fan as its balance could be

affected by poor handling.

Fan installation is performed in the reverse order of its removal.

Upon completion of installation, rotate the impeller by hand to

ensure that there is no contact with the inlet ring.

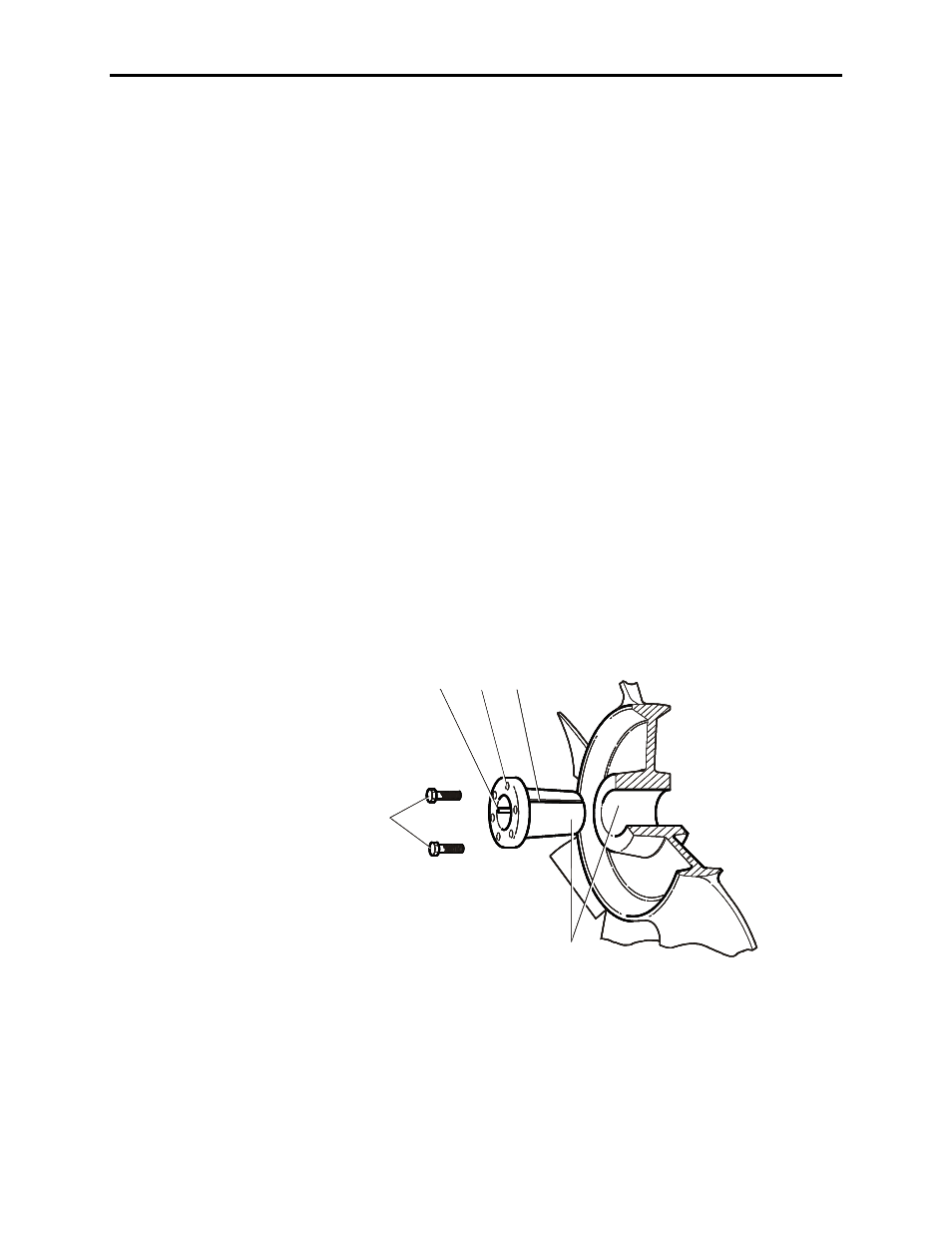

Impeller Maintenance

Impeller Removal from Motor Shaft

The fan impeller is held onto the motor shaft with a split tapered

bushing. This bushing is positioned on the motor shaft and through

the center of the impeller. Two capscrews, when tightened to

10.2 N-m (7.5 ft-lbs.), lock the bushing onto the motor shaft and

the impeller to the bushing.

Safety notes

The impeller is fragile. Do not allow the impeller to support the

weight of the motor.

If vertical, the impeller and bushing may fall when loosening

capscrews. Physical injury or component damage may result.

A

B

C

D

E

A – Taper surfaces

B – Capscrews

C – Split in Taper Bushing

D – Key

E – Threaded Hole for Separating Tapers

DO NOT LUBRICATE

CAPSCREWS, BORE

OR BUSHING BARREL

A

B

C

D

E

A

B

C

D

E

A – Taper surfaces

B – Capscrews

C – Split in Taper Bushing

D – Key

E – Threaded Hole for Separating Tapers

DO NOT LUBRICATE

CAPSCREWS, BORE

OR BUSHING BARREL

Figure 6.44 – Impeller Removal