After designation, Table 13 - qualification status interpretation – Rockwell Automation 1756-RMxx ControlLogix Enhanced Redundancy System User Manual User Manual

Page 73

Rockwell Automation Publication 1756-UM535D-EN-P - November 2012

73

Install the Enhanced Redundancy System

Chapter 3

After Designation

When you first apply power to the designated primary and secondary chassis,

compatibility checks are carried-out between the redundant chassis. Then,

because the default Auto-Synchronization parameter is set at Always,

qualification begins.

Use this table as a reference when interpreting the qualification status of the

modules displayed on the module status display.

.

Conversion from a Nonredundant to a Redundant System

You can upgrade the standalone chassis to a redundant chassis pair, by inserting a

redundancy module in the standalone chassis and setting up an identical chassis

with compatible modules (including the redundancy module) in the same slot as

the standalone chassis.

If the partnered chassis, containing nonredundant modules or nonredundancy

compliant firmware, is designated as the secondary chassis, it will stop

functioning.

For detail information, see

Convert from a Nonredundant System on page 265

TIP

While the qualification occurs, the module status display transitions from

DISQ (disqualified) to QFNG (qualifying) to SYNC (synchronized). The

qualification s completes in 1…3 minutes and then module status

display indicates the qualification status.

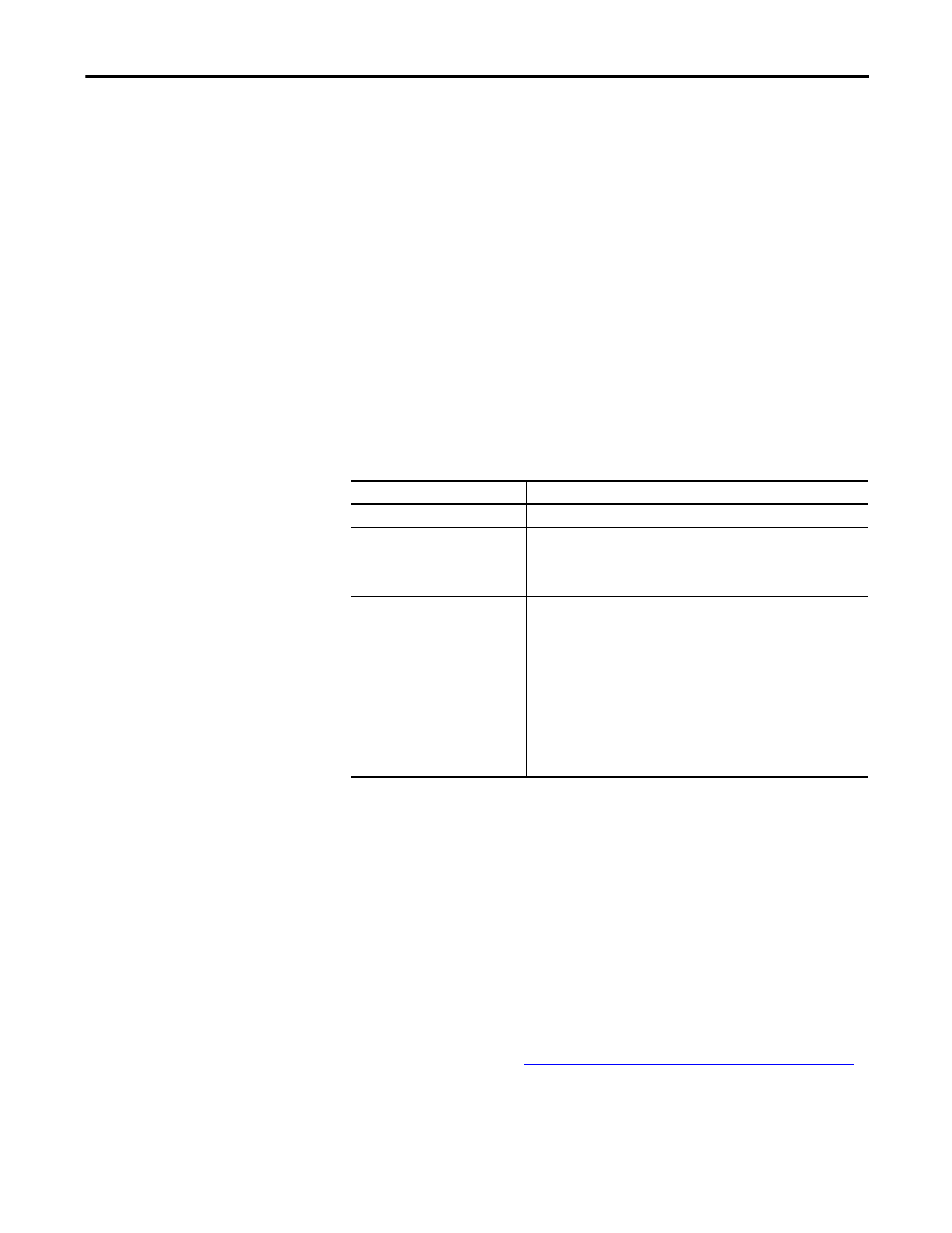

Table 13 - Qualification Status Interpretation

Module Status Display

Interpretation

QFNG

Qualification processes are in progress.

SYNC

SYNC displays after qualification processes are complete.

This indicates that chassis configuration and the firmware revision levels are

compatible and that the secondary chassis is ready to assume control in the

event of a major fault in the primary chassis.

DISQ…QFNG…DISQ

If DISQ continues to display after about three minutes, one of these anomalies

exists:

• Incorrect chassis configuration. That is, incompatible hardware is used.

• Incompatible firmware revisions are used between the primary and

secondary modules.

• Keeper parameters between ControlNet module partners are not the

same.

• The partnered ControlNet modules are not set to the same node address.

• The Auto-Sychronization parameter within the Redundancy Module

Configuration Tool is set to Never.