Using hmi, Hmi connected via an ethernet/ip network – Rockwell Automation 1756-RMxx ControlLogix Enhanced Redundancy System User Manual User Manual

Page 46

46

Rockwell Automation Publication 1756-UM535D-EN-P - November 2012

Chapter 2

Design an Enhanced Redundancy System

Using HMI

Depending on the network used to connect the redundant system to HMIs, plan

for certain placement and configuration requirements. You can connect an HMI

to a primary chassis over either of these networks:

• EtherNet/IP

• ControlNet

HMI Connected via an EtherNet/IP Network

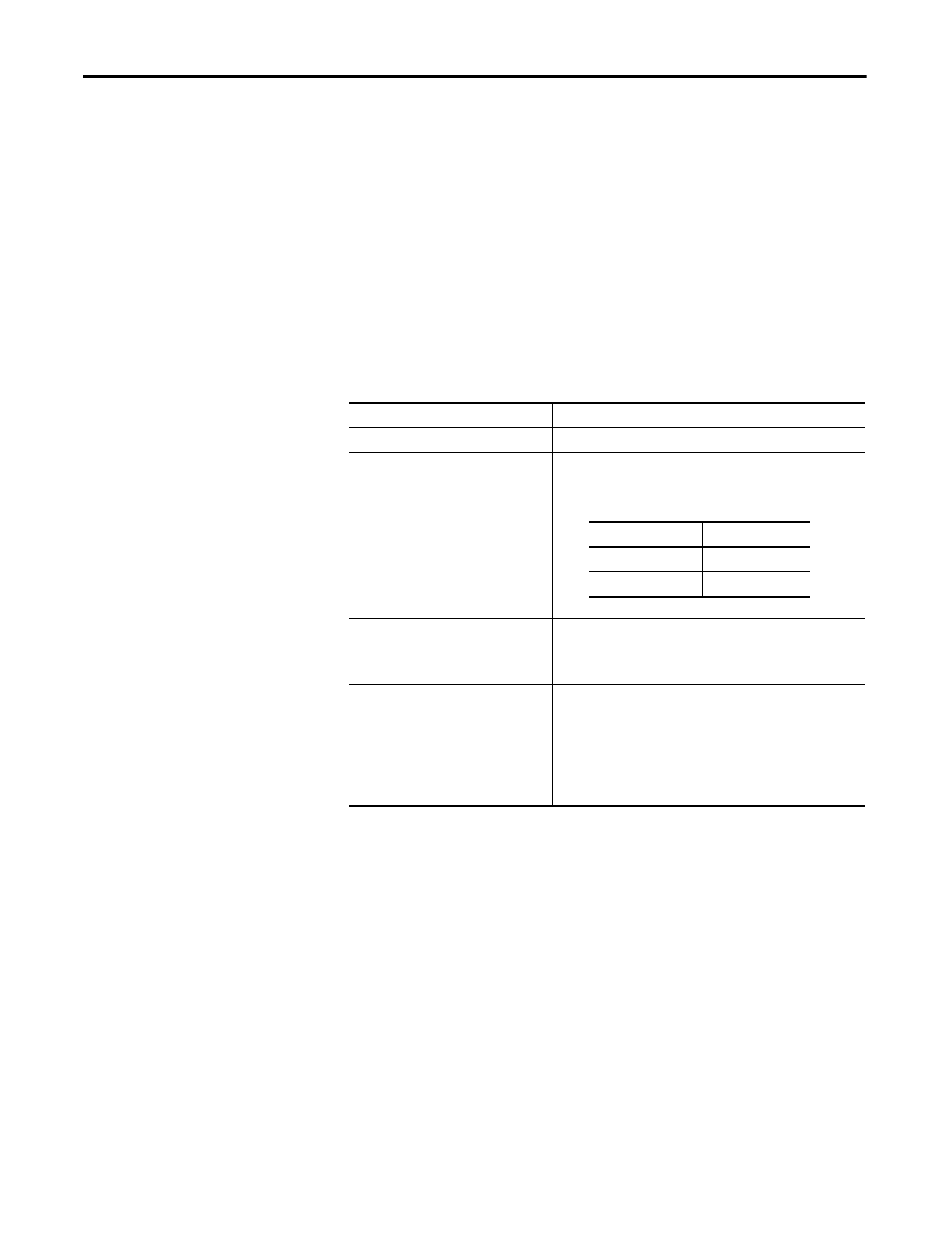

This table describes redundant system considerations specific to the HMI being

used on the EtherNet/IP network.

HMI connected to a redundant chassis pair exclusively over an EtherNet/IP

network can briefly drop the connection when a switchover occurs. The

connection is re-established, however, after the switchover is complete.

Type of HMI Used

Considerations

PanelView Standard terminal

Same as a nonredundant system.

• PanelView Plus terminal

• VersaView® industrial computer running

a Windows CE operating system

• Use RSLinx Enterprise software, version 5.0 or later.

• Set aside connections for each PanelView Plus or VersaView CE

terminal as indicated in this table.

FactoryTalk View Supervisory Edition

software with RSLinx Enterprise software

• Use RSLinx Enterprise communication software, version 5.0 or later.

• Keep the HMI and both redundant chassis on the same subnet.

• Configure the network to use IP swapping.

• FactoryTalk View Supervisory Edition

software with RSLinx Classic software,

version 2.52 or later

• RSView®32 software

• Any other HMI client software that uses

RSLinx Classic software, version 2.52 or

later

Limit the number of RSLinx servers that a controller uses to 1…3

servers, where the use of 1 server is ideal.

In this module

Reserve

Controller

5 connections

1756-EN2T

5 connections