Pulsafeeder Pulsar DLC User Manual

Page 92

87

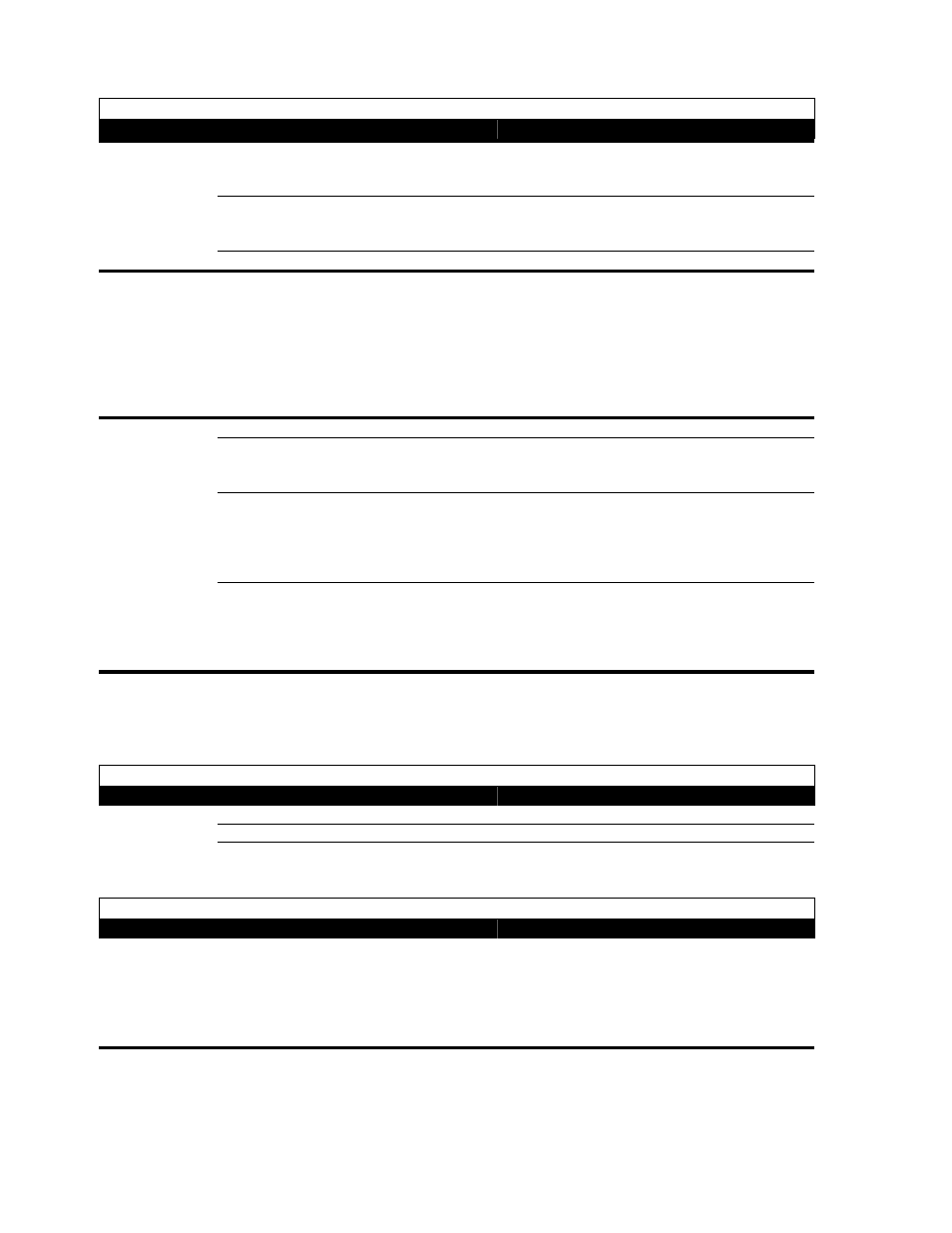

MANUAL ADJUSTMENT KNOB / DLC INTERNAL DRIVE MOTOR

Symptom

Probable Cause

Possible Solution

PULSAR Stroke Adjustment jammed on

mechanical stop at 0%.

Remove DLC. Turn shaft counter-clockwise

with crescent wrench on flats to free.

Re-install DLC. Re-calibrate flow.

PULSAR Stroke Adjustment jammed on

mechanical stop at 100%.

Remove DLC. Turn shaft clockwise with

crescent wrench on flats to free. Re-install

DLC. Re-calibrate flow.

Knob will not

turn under DLC

control or by

hand.

DLC gearing worn.

Contact Technical Services.

Knob will not

turn under DLC

control.

Display shows

{DUTY

CYCLE}.

Internal DLC Synchronous motor has

achieved its duty cycle limit of 50% ON

time (based on a 20 minute interval).

Rapidly cycling batches and wildly

swinging analog inputs will cause this

motor to run continuously.

Eliminate batches that are cycling too rapidly

(e.g., changing stroke from 0 to 100% one

minute and 100 to 0% the next - the internal

drive motor runs all the time). Condition

analog input signal. Cycle Power.

Wait for 'cool-down' period.

Refer to Section 5 – Installation: High

Voltage Connections, PULSAR MOTOR.

Motor Starter wired incorrectly.

Motor starter must be wired through the DLC.

The Stroke Position encoder is bad.

Cycle power and attempt re-calibration. If

Encoder diagnostics appears, contact

Technical Services.

The Stroke Position gear train has failed.

Cycle power. Use [UP] and/or [DOWN] to set

stroke to 50% while the DLC stroke motor is

running. Adjust knob by hand. Feel for

smooth operation and “Catching”. Contact

Technical Services.

Know will not

turn under DLC

control.

Display shows

{POSITION

ERROR}. The

DLC has

attempted to

move the stroke

adjustment for

at leat 10

minutes with no

movement

determined.

The Stroke Adjustment is jammed.

Rotate adjustment in the direction opposite to

the current position (i.e., at 100% rotate

clockwise, at 0% rotate counter clockwise.

Knob turns at

power-up.

Normal Zero Calibration . Display should

read {PLEASE WAIT / CALIBRATING

ZERO}.

Do not turn knob by hand while DLC's power

is off.

KEYPAD

Symptom

Probable Cause

Possible Solution

Display does

Software did not initiate properly.

Cycle power.

Not respond

Memory Corrupted.

Cycle power. Perform Factory Re-Initialize.

To keypad

Keypad connector loose.

Contact Technical Services.

Entry.

BATCH OPERATION

Symptom

Probable Cause

Possible Solution

Activated batch

appears to be

running through

batches rapidly.

Repeating Batch activated with Old Start

Date. For example, today is 1/22/01, You

have a repeating batch programmed to start

on 1/5/01). The display will show the 'run-

through' of all batches between the start

day and time and today.

Change Batch start-time/date to current or

future date/time.

Repeating

Batch will not

start.

Batch duration is set to 0 hours and 0

minutes.

Duration must be greater than 0 minutes for

batch to activate.