7 tachometer input (optional), 3 digital output – Pulsafeeder Pulsar DLC User Manual

Page 22

17

5.6.3 Digital Output

The Digital Output can be configured through software to indicate one of the following:

a) Pump Motor status – (on or off).

b) Pump stroke (generates a pulse with every pump stroke for use with an external stroke counter).

The Stroke output is not in phase with the pump stroke but has a 50% duty cycle (e.g., the output is

ON for half of the stroke and OFF for the other half).

c) Mode Indication (Manual, Analog, or MODBUS)

An opto-coupler is used to achieve total isolation of this output. As such, the external control

equipment must generate the supply on the positive output and detect the return of that signal from the

DLC. In a typical application, use 0.32mm

2

– 0.52mm

2

(22-20 AWG) wire to attach the terminal

labeled '5-STATUS(+)' – the collector terminal – to the external equipment's logic supply. Connect the

terminal labeled '6-STATUS(-)' – the emitter terminal – to the positive input of the equipment. The

negative input of the equipment should be connected to its isolated ground. A series resistance of 400

ohms is recommended – especially when sinking current (e.g., a photo-diode of an opto-isolator).

There is also an internal stroke counter that is re-settable. Refer to Section 7.2 - Menu –

Diagnostics – Diag. Menu 11/11.

5.7

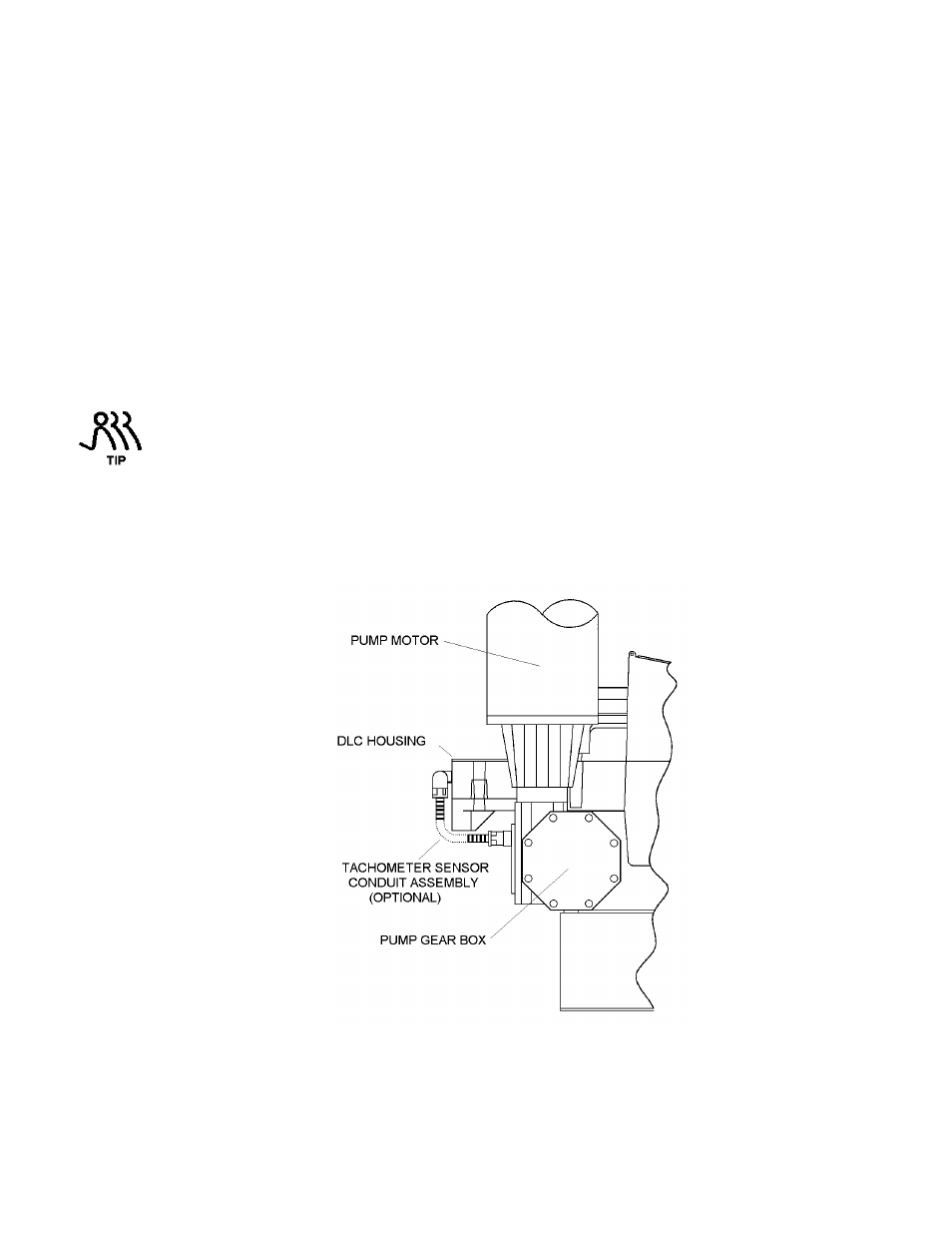

Tachometer Input (optional)

The Tachometer Sensor is connected to the Tachometer Input. It senses motor rotation. This input allows

the DLC to count pump strokes if so equipped.

Figure 7 – Tachometer Sensor Conduit Assembly