Remote detector rccs3, option- code – Yokogawa RotaMASS 3-Series User Manual

Page 240

11. TECHNICAl dATA

11-18

IM 01R04B04-00E-E 8th edition March 01, 2011 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

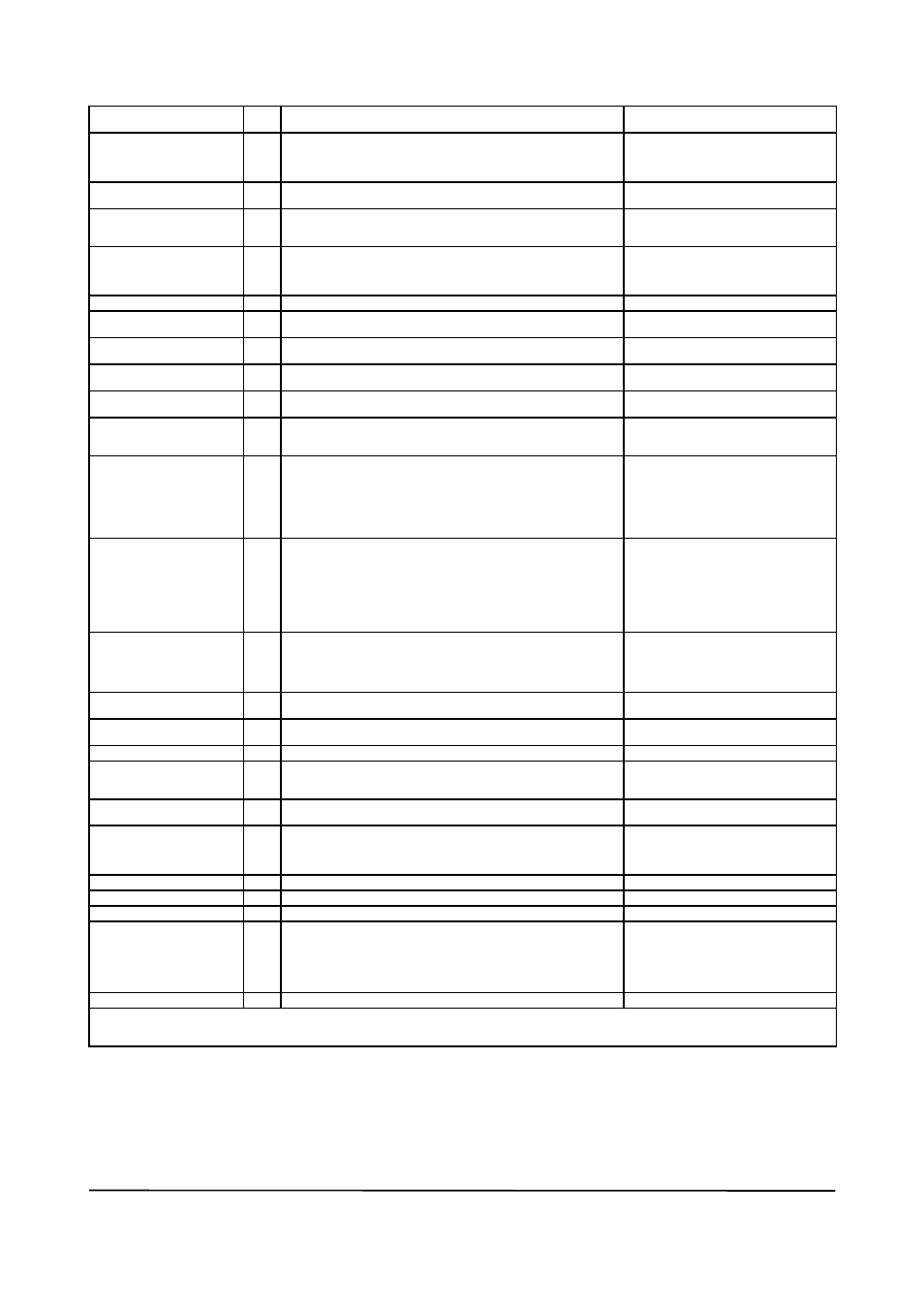

remote detector rCCS3, Option- Code :

Options

Option

code

description

restrictions

Hazardous Area Approvals

1)

/KS1

/FS1

/ES1

/US1

ATEX intrinsically safe approval

FM intrinsically safe approval for USA + Canada

IECEx intrinsically safe approval

INMETRO intrinsically safe approval for Brazil

only with cable conduit ´A´

Custody Transfer Measurement

acc. OIML R 117-1

/Q01

European MID Approval (fluids other than water) (refer to GS 01R04B07-00E)

GOST Approval

1)

/QR1

/QR2

/QR3

Russian GOST approval

Kazakh GOST approval

Uzbekistan GOST approval

see chapter 9.5; not with /LT

see chapter 9.5; not for RCCS39/XR; not with /LT

see chapter 9.5; not for RCCS39/XR; not with /LT

Dual Seal Approval

/DS

/RD

Dual Seal approval (conform with ANSI/ISA-12.27.01)

Rupture disk

only RCCS34 to 39/XR; only with /FS1; not with

process connection A5

only RCCS34 to 39/IR, preferable with /GA, not

with /Tx, mandatory if /DS + /GA is selected

Tag Number

/BG

With customer specified tag number on name plate

max. 16 digits

Flange Facing

/DN

/RJ

Flange with safety grooves acc. to EN 1092-1 form D

Ring Type Joint Flanges

only for D2 to D6; not HC

only for A3, A4, A5; not HC

Gas Measurement

/GA

Gas measurement, special factory adjustments and settings

select affiliated RCCF31 or RCCR31 with /GA;

to be conform with ANSI/ISA-12.27.01 select /RD

Low temperature version

/LT

-200°C < T

medium

< 150°C

not RCCS30 to 33; not with /KS1, /FS1, /ES1,

/US1, /MT, /HT, /T1, /T2, /T3, /QR1, /QR2, /QR3

Extended temperature range

/MT

-70°C < T

medium

< 230°C

not RCCS30 to 33; always with /S2 or /Tx;

remote cable RCCY033/034 recommended

High temperature version

/HT

T

medium

up to 350°C

only with /Tx or /S2 (customer insulation required);

only RCCS34 to 39/IR;

remote cable RCCY033/034 recommended

Special Calibration

/K2

2)

/K4

/K5

2)

/K6

Custom 5 pts mass-/volume-flow calibration using water with factory certificate

(traceable to German national standards)

Density adjustment + thermal treatment; (accuracy: 0.001 g/cm³)

Custom 10 pts mass-/volume-flow calibration using water with DKD certificate

(according EN-17025:2005)

Density calibration with 3 different fluids incl. individual temperature compensation

with certificate (accuracy: 0.0005 g/cm³)

only RCCS31 to 39; not with /GA

only RCCS32 to 39; not with /GA; only available if

converter is also ordered

Certificates

/P2

/P3

/P6

/P8

/H1

/WP

Certificate of compliance with the order acc. to EN 1024:2004 -2.1

As /P2 + Test report acc to EN 1024: 2004 -2.2 (QIC)

Material certificate acc to EN 1024: 2004 -3.1

Pressure test report measuring system

Oil and fat free for wetted surface acc. to ASTM G93-03 level C

WPS acc. DIN EN ISO 15609-1 (Welding Procedure Specification)

WPQR acc. DIN EN ISO 15614-1 (Welder Performance Qualification Record)

WQC acc. DIN EN 287-1 (Welder Qualification Certificate)

only for butt weld between process connection

and flow divider; not for HC

Sanitary Type

/SF1

/SF2

/SA

/SE

Surface roughness Ra = 0.8 µm

As /SF1 + Test report roughness of wetted parts

As /SF2 + 3A- declaration of conformity and 3A- mark

As /SF2 + EHEDG- certificate

only RCCS34 to 39/IR; only process connections

S2, S4, S8; see also restrictions in table 11-10

not with process connection S2

not with process connection S2

Mounting set

/PD

2 inch pipe mounting set

only RCCS30 to 33; not with /Tx; recommended

for RCCS30

Housing Pressure Test

/J1

Rupture pressure proof test and certificate:

60 bar (RCCS34, RCCS36), 40 bar (RCCS38), 10 bar (RCCS39, RCCS39/IR)

not for RCCS30 to 33 + RCCS39/XR

Customer insulation / Heating

/S2

Terminal box on extension for high or low process temperature

not with /T1 ... /T3

Factory Insulating / Heating

/T1

/T2

/T3

Insulation

Insulation + Heat carrier heating

Insulation + Heat carrier heating with ventilation (purge)

not for RCCS39/XR

not for RCCS39/XR

not for RCCS39/XR

X-Ray Examination

/RT

X-ray examination of flange welding

RCCS30 to 33 and RCCS34 with /K4, /K6 or /LT

only one-sided

PMI Examination

/PM4

/PM6

PAMI test (4 test points: process connection inlet + outlet, flow divider inlet +

outlet)

3)

PAMI test (6 test points: process connection inlet + outlet, measuring tubes, flow

divider inlet + outlet)

3)

only RCCS30 to 33

not RCCS30 to 33

Dye Penetration Test

/PT

Dye penetration test of flange welding

Stainless steel cable gland

/BS

Cable gland stainless steel

Delivery to Japan

/PJ

For meters which are delivered to Japan

Quick Delivery

/QD

Delivery within 24 hours from factory

only RCCS34 to 39

not with process connection size 23, 12,

only with process connection rating A1, A2, D4,

only material SL,

only for options /KS1, /FS1, /ES1, /US1, /BG,

/P2, /P3, /P8

Special order

/Z

Special design must be specification an extra sheet

1)

Select affiliated converter RCCF31/RCCR31 with the same approval type (e.g. ATEX).

2)

Calibration order sheet must be delivered with the order. This is available on the Flow Center Page at Coriolis/RCCx3/Technical Information.

3)

Measuring tube PAMI test is performed per delivery batch.