Information of potential hazardous situations – Yokogawa RotaMASS 3-Series User Manual

Page 222

10. pEd (prESSUrE EqUIpMENT dIrECTIvE)

10-4

IM 01R04B04-00E-E 8th edition March 01, 2011 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

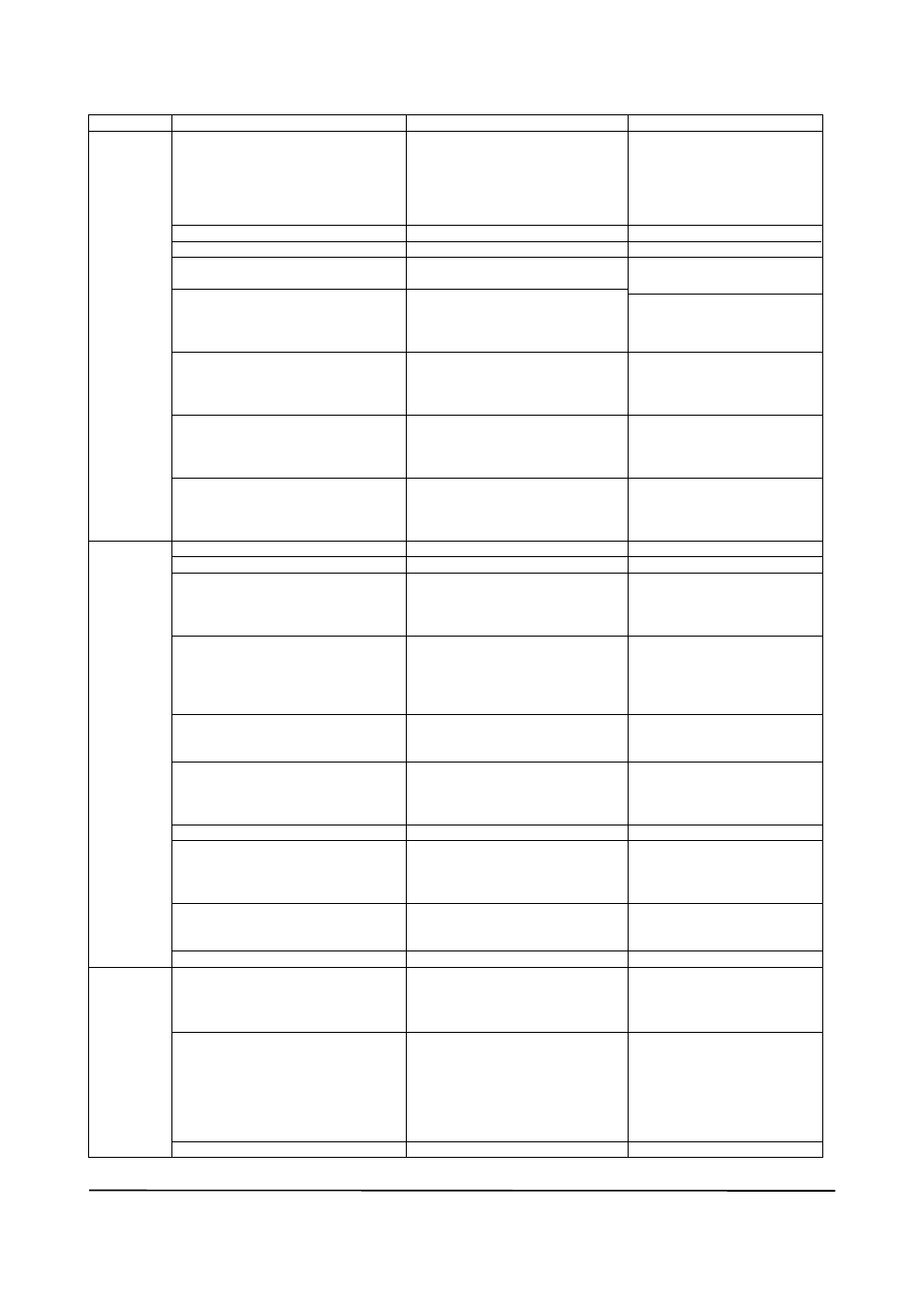

Information of potential hazardous situations:

Endangering by:

Description

Remarks

Surface temperature

Surface temperature is hot in case of

high process temperature. It is the

sole responsibility of the user to

establish proper means to prevent

touching of the detector (see also

chapter 11.1).

Max. / Min process temperature

See chapter 11.1

Max. process pressure

See chapter 11.1

Tightness of the wetted, PED relevant

volume

A factory test is done before delivery

Corrosion and erosion effects

It is the sole responsibility of the

user to select proper wetted

materials for the medium intended

to use (see chapter 10).

Life time evaluation

Experience shows that the lifetime of

the detector within the allowed

operation conditions is more than 10

years.

Without erosion and corrosion.

Temperature shock

Permanent temperature cycles of

more than 100°C temp. difference

have to be avoided. Tube failure can

occur because of material wearing.

Medium

Instable fluids

If instable fluids are transported it is

the sole responsibility of the user

that in case of decomposition the

design limits are not exceeded.

Process pressure/temp. relation

See chapter 10

Piping and support forces

See chapter 4.3

Choice of gaskets and pre- stress of the

process connections

It is the sole responsibility of the

user to select suitable gaskets and

to screw the process connections

with the necessary torques.

Refer to EN 1591-1

Use of closing and openings

Do not open the ¼ NPT plugs in the

body after tube failure before it is

ensured that the housing is pressure

free and free of hazardous

substances.

Pressure shock, water hammer and

pressure surges

Dynamical exceeding of the given

max. pressure at process temp. has

to be avoided.

Water hammer can lead to tube

failures.

Filling and emptying of the pipe work

The detector is part of a pipe work. It

has to be taken into account that

fluid can remain in the measuring

tubes.

Disposal, cleaning and return

See chapter 1.5

Flow direction of the unit

See chapter 4.1 and marking on the

detector.

After installation with wrong flow

direction only indication error

(wrong sign, can be corrected via

software)

Installation position of the unit

See chapter 4.3

A wrong installation position gives

only measuring disturbances

Installation

Pipe stress by weight of the instrument

See chapter 4.3

Permitted ambient conditions

(temperature, humidity)

See chapter 11.1

External fire

External fire can result in

- Rise in pressure by temperature

- Damage of gaskets

It is in the sole responsibility of the

user to implement suitable means to

prevent large damage in the case of

fire.

The instrument itself does not

contain flammable materials.

Outer

influence

Earthquake resistance

Damage of the mounting screws

Check by user

T101.EPS