3 model, suffix and option codes, 3 model, suffix and option codes -15, Integral type rcct3, modell- and suffix- code – Yokogawa RotaMASS 3-Series User Manual

Page 237: Integral type rcct3, option- code

11. TECHNICAl dATA

11-15

IM 01R04B04-00E-E 8th edition March 01, 2011 -00

All Rights Reserved. Copyright © 2003, Rota Yokogawa

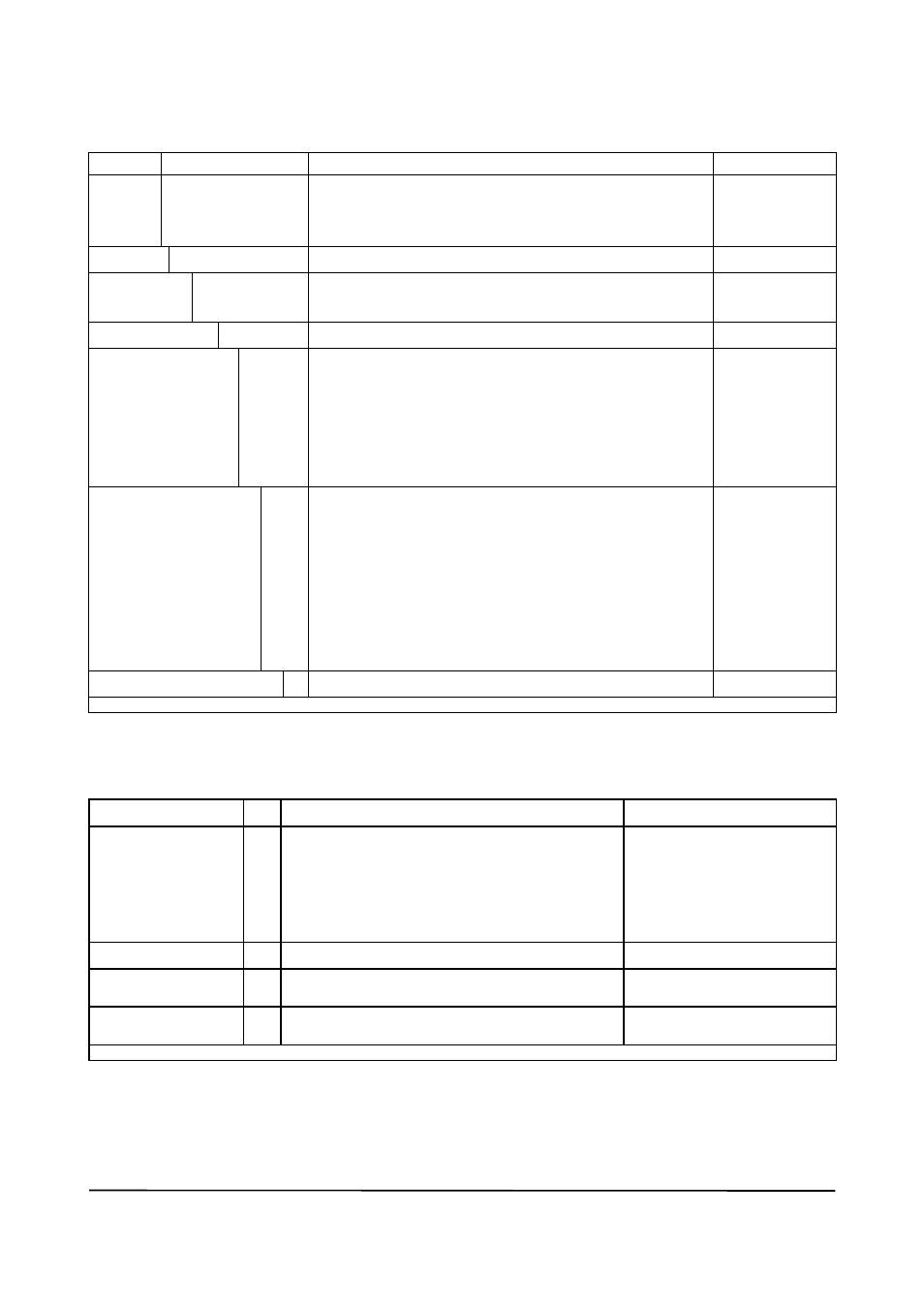

11.3 Model, Suffix and Option Codes

Integral type rCCT3, Modell- and Suffix- Code :

Model

Suffix Code

description

restrictions

RCCT34

RCCT36

RCCT38

RCCT39

RCCT39/IR

RCCT39/XR

Nominal Value : 3 t/h = 50 kg/min

Nominal Value : 10 t/h = 170 kg/min

Nominal Value : 32 t/h = 533 kg/min

Nominal Value : 100 t/h = 1670 kg/min

Nominal Value : 250 t/h = 4170 kg/min

Nominal Value : 500 t/h = 8340 kg/min

only with /HP

Power supply

-A

-D

90 - 264 V AC

24 V DC

Indicator direction

H1

H2

V0

N0

Detector installation horizontal, tubes down

Detector installation horizontal, tubes up

Detector installation vertical

Without indicator

recom. for liquid service

recom. for gas service /GA

Cable conduit connection

M

A

M20 x 1, female thread with cable glands

ANSI ½´´ NPT, female thread without cable glands

mandatory with /FF1, /FF3

Process connection size

1)

23

01

02

04

05

06

08

10

12

15

20

¾´´

DN 15, ½´´

DN 25, 1´´

DN 40, 1½´´

DN 50, 2´´

DN 65, 2½´´

DN 80, 3´´

DN 100, 4´´

DN 125, 5´´

DN 150, 6´´

DN 200, 8´´

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

Process connection rating and style

1)

A1

A2

A3

A4

A5

D2

D4

D5

D6

J1

J2

S2

S4

S8

G9

T9

ASME flange class 150, process connection dim. + facing acc. ASME B16.5

ASME flange class 300, process connection dim. + facing acc. ASME B16.5

ASME flange class 600, process connection dim. + facing acc. ASME B16.5

ASME flange class 900, process connection dim. + facing acc. ASME B16.5

ASME flange class 1500, process connection dim. + facing acc. ASME B16.5

EN flange PN 16, process connection dim. + facing acc. EN 1092-1 Form B1

EN flange PN 40, process connection dim. + facing acc. EN 1092-1 Form B1

EN flange PN 63, process connection dim. + facing acc. EN 1092-1 Form B2

EN flange PN 100, process connection dim. + facing acc. EN 1092-1 Form B2

JIS flange 10K, JIS B 2220

JIS flange 20K, JIS B 2220

Thread acc. DIN 11851

Clamp, process connection dimensions acc. DIN 32676

Clamp, process connection dim. acc. Tri-Clover (Tri-Clamp) and ½´´ Mini Clamp

G, female thread

NPT, female thread

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

see table 11-10

Material of wetted parts

1)

SL

HC

Stainless steel 316L (1.4404)

Hastelloy C-22 (2.4602)

only RCCT34 to 39/IR

1)

see selection table „Process connection and materials“ (table 11-10)

Integral type rCCT3, Option- Code :

Options

Option

code

description

restrictions

Hazardous Area Approvals

/KF1

/KF2

/FF1

/FF2

/EF1

/EF2

/UF1

/UF2

ATEX Flame proof converter + Intrinsic safe detector

ATEX Flame proof converter + Intrinsic safe detector + Intrinsic safe outputs

FM approval for USA+Canada, Flame proof converter + Intrinsic safe detector +

2 active analog outputs + 2 passive pulse outputs + 1 status input

FM approval for USA+Canada, Flame proof converter + Intrinsic safe detector +

1 passive analog output + 1 passive pulse output

IECEx Flame proof converter + Intrinsic safe detector

IECEx Flame proof converter + Intrinsic safe detector + Intrinsic safe outputs

INMETRO Flame proof converter + Intrinsic safe detector

INMETRO Flame proof converter + Intrinsic safe detector + Intrinsic safe outputs

with /HP for gas group IIB

with /HP for gas group IIB

only with cable conduit ´A´; with /HP not for

groups A and B

only with cable conduit ´A´; with /HP not for

groups A and B; not

with /HP for gas group IIB

with /HP for gas group IIB

with /HP for gas group IIB

with /HP for gas group IIB

Custody Transfer Measurement

acc. OIML R 117-1

/Q01

European MID Approval (fluids other than water) (refer to GS 01R04B07-00E)

GOST Approval

/QR1

/QR2

/QR3

Russian GOST approval

Kazakh GOST approval

Uzbekistan GOST approval

see chapter 9.5

see chapter 9.5; not for RCCT39/XR; not with /HP

see chapter 9.5; not for RCCT39/XR; not with /HP

Dual Seal Approval

/DS

/RD

Dual Seal approval (conform with ANSI/ISA-12.27.01)

Rupture disk

only with /FF1; not with process connection A5;

not wit RCCT39/XR, preferable with /GA,

mandatory if /DS+/GA is selected

1)

This is a flame proof device, not an intrinsic safe device!