Multiple pid sets, Burst fire, Burst fire (variable-time base) – Watlow Series F4P User Manual

Page 66

7 . 8

■

F e a t u r e s

Wa t l o w S e r i e s F 4 P

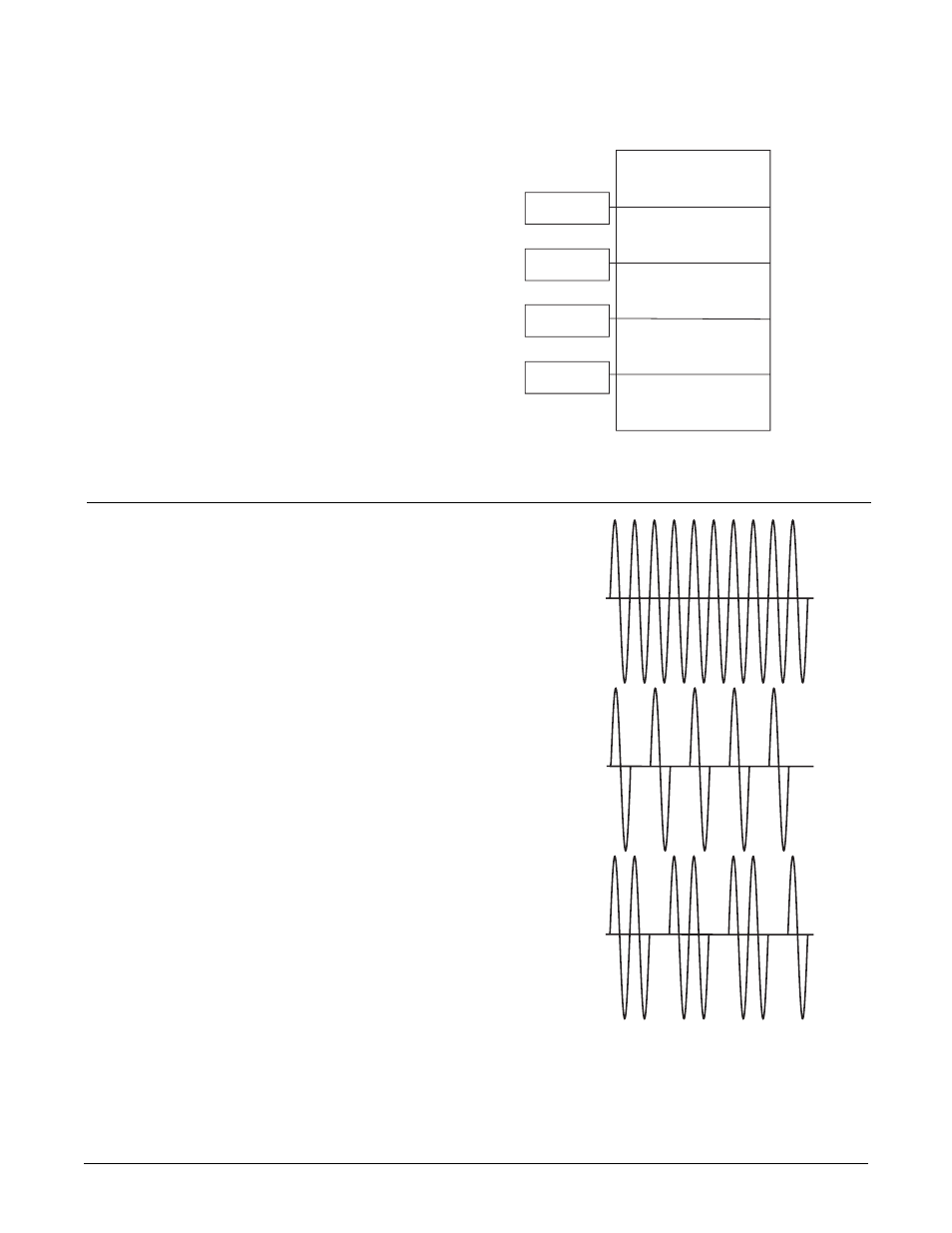

Multiple PID Sets

The Series F4P supports up to five heat/cool PID sets.

This feature is extremely valuable if the characteristics

of your thermal system vary over its operating range. All

PID sets can be auto tuned or manually tuned. PID sets

can be edited in the Operations Page. The Series F4P can

be programmed to operate using any of the five sets

based on crossover points of the set point or process val-

ue. These programming choices are made in the Opera-

tions Page > PID Crossover.

When the process or set point value crosses the crossover

point, the PID set designated for that region of the oper-

ating range is used to control the percent power being

supplied to the load.

There is a -1° hysteresis for each crossover. A rising tem-

perature will change PID sets at the crossover value. A

falling temperature will change PID sets at the crossover

value -1°.

Location in software: Operations Page > Edit PID > PID

Crossover x (1 to 4).

Figure 7.8a — Multiple PID Sets.

Range High = 1,500

°

F

Range Low = 32

°

F

Operating Range PID Set 5

Operating Range PID Set 4

Operating Range PID Set 3

Operating Range PID Set 2

Operating Range PID Set 1

PID Cross 4 to 5

1,250

°

F

PID Cross 3 to 4

1,000

°

F

PID Cross 2 to 3

600

°

F

PID Cross 1 to 2

300

°

F

Burst Fire (variable-time base)

Burst firing provides even output power with the lowest

level of noise generation (RFI). Burst fire is the preferred

method for controlling a resistive load, providing a very

short time base for longer heater life.

The controller determines when the ac sine wave will

cross the 0-volts point, then switches the load on or off

only at this point, minimizing RFI.

Location in software: Setup Page > Control Output x (1A

or 1B).

Figure 7.8b — Burst Fire.

66% output

2 ON, 1 OFF

50% output

1 ON, 1 OFF

100% output

10 ON, 0 OFF